David Graves and Greg Gruszecki, the two young entrepreneurs behind start-up OmnyDynamics want to get into the 3D printing market by launching Strooder, which is meant to be the first truly accessible plastic filament extruder, with the potential to make ready bought filament spools a thing of the past (at least for most plastic materials) and thus slash the cost of consumables in the 3D printing market. They have built it from the ground up and are going close to launching a Kickstarter campaign targeting a £249 retail price.

I caught up with the guys recently.

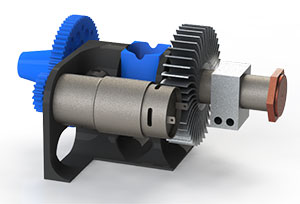

“We have the case and we have the internals,” says Graves, “they are being designed separately. What we aimed for is simplicity. the casing introduces a safety aspect so that there are no exposed heated or mechanical parts. But we also kept an eye out for aesthetics and tried to make it as compact as possibile.”

The team at OmniDynamics has no prior entrepreneurial experience but they seem to have a clear understanding of the market and the needs they want to cater for. Their main objective has been to make the Strooder easy to use without extensive experience and familiarity with the technical properties of thermoplastics.

As rapidly expanding as the desktop 3D printer market is, not enough attention seems to be directed toward products that act as a complement to it, enabling the processes that take place before and after the actual 3D printing. OmniDynamics’ idea is targeting one of these processes and, while there are some prosumer machines that turn pellets into filament, they do not yet come close to fully satisfying the market’s demand: that is where the Strooder, which promises to be an affordable and extremely easy to use filament extruder, comes in.

Furthermore, the guys are looking at eliminating the need to buy filament altogether by enabling rapid and effective recycling. “There are five main types of recyclable plastics – says Graves – they all melt at the temperature that our extruder is capable of achieving. We can’t wait to put failed prints back through the extruder and our theory suggests there would be no reason why we would not be able to use PET from plastic bottles as well”.

Some people point to the 3D printing industry following certain dynamics that characterized the 2D printing industry, such as the development of a home market alongside a professional printing store market. 3D printing, however, is so much more than 2D printing, and not just for the added dimension, or, actually, just for that. That added dimension means so much more than seeing the image of something on paper. In this late stage of the 2D printing industry most revenue and profits come from consumables. Eliminating a large part of consumables by allowing for effective recycling or home production will definitely set the 3D printing industry apart from its 2D ancestor. Will it be the Strooder that will make this happen? We’ll likely find out when it hits Kickstarter soon.