An ever increasing range of items are being three dimensionally printed. Of those many items, there are some that people may anticipate more than others. Intricate sugar sweets, bioprinted human ears, whole printed houses, and awesome 3D printed guitars have streched our anticipation and what to expect from this innovative set of technologies. Perhaps it is not such a suprise then that 3D printed bow ties are already with us. Is this a gimmick or a real fashion innovation? Or maybe simply something more fun than that?

I’m going to share my complete lack of experience here. I’ve never worn a bow tie. Indeed bow ties aren’t something that I’ve particularly thought about before. The closest I’ve come to an appreciation of bow ties was probably the first time that I heard the sound of a Tie Fighter on a Star Wars movie. I mean, a bow tie is a bow tie isn’t it? My lack of experience shows and a question is raised. What happens when you put 3D printing together with something as relatively innocuous as a bow tie?

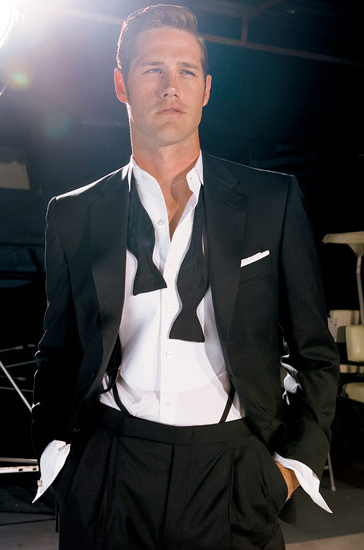

Or, if you are super cool:

FAB&DANDY

As Mr. Smith explains on the FAB&DANDY website: ‘After graduation, I returned my efforts to investigating 3D printing in the retail market, specifically wearable goods as it was clear that this transformative technology could redefine how we view fashion. Months of industry investigation and design run trials culminated in what you see before you, less ‘economically driven business’, but more ‘showcase of cutting edge design’ geared towards providing an explorative platform for those with an interest, budding or entrenched, in the cross section of ultra modern design concepts made physical by emerging high-tec fabrication. This is the goal of FAB&DANDY, and it is an ethos of explorative, innovative design that stimulates, educates and decorates.’

What 3D printing arguably does best is allow the creation of complex geometric forms that cannot be crafted by other means. Additive techniques have the capacity to take a form and hone it to an aesthetic and/or function in ways previously unseen. It is this capacity that has perhaps featured the most often in the applications of additive manufacturing technologies for clothing.

For bow ties, the same essential principle is true. What point 3D printing that which can be crafted by other means unless a genuine benefit emerges from novel features — or cost efficiency. The genuine benefit here is principle of the efficient creation of complex geometric forms that cannot be readily crafted by other means. Making stuff that looks difficult to make, but is not difficult to make. Showcasing possibilities for a new way of making. Doing something that is different, but the difference is worthwhile.

Fab & Dandy is not just innovating designs, they are also actually selling their bow ties. There is a market. This is a business. Oliver says that these intriguingly fashioned collar ornamentations are proving particularly popular in America.

There have been a couple of other companies and individuals who have designed and produced 3D printed bow ties, this is not a unique application or a world first. But what Fab & Dandy is showing is a good example of what happens when innovative concepts are pushed to a full exploration of their potential. And also something quite special about the ‘desktop factory’ implications of 3D printing. If you have an idea, a skill base, you can own the means of producing those ideas, and kickstart a business model. You can get those ideas out of your head and into reality.