Refil, a Netherlands based startup founded by alumni from the Delft University of Technology and members of the Better Future Factory design studio, has launched its latest PLA filament, made from fully recycled yogurt pots.

The new PLA 3D printing material has the same qualities as newly manufactured “virgin” filament and is suitable for both beginners and professional users of 3D printing, according to the company.

A better world, one yoghurt at a time

Refil is attempting to address what it describes as “the plastic problem”. Plastic is made using vast quantities of oil and natural gas, which are limited natural resources that provide the raw monomers for plastic production. Much plastic also ends up in landfill or in “plastic soup” within oceans, interfering with animal ecosystems and contributing to climate change.

Each new spool of Refil’s new filament range is made from 750 grams of recycled plastic. The refinement process used in producing the spools of filament reduces noxious fumes when melting the filament. The spools holding the filament are made from recycled cardboard.

The filament

The 3D printer filament is available in a natural white colour, and it is suitable for printing at 210°C. The standard diameters available are 1.75mm and 2.85mm. Tests by Refil found minimal warping and easy print bed adhesion for the material.

Another ecosystem saved

Refil has previously created 3D printing filament from the dashboards of old cars. The project, launched following a successful Kickstarter in 2015, involves shredding the used car dashboards, melting them down, and then turning them into PLA filament also suitable for 3D printing via FFF.

In the same year, Refil received a boost after fellow Netherlands based OEM Ultimaker announced its support for the Perpetual Plastic Project.

Similar projects producing 3D printing filament from recycled plastics have been launched by The Plastic Bank, Filacycle, and Reflow.

For more on environmentally-friendly 3D printing projects, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

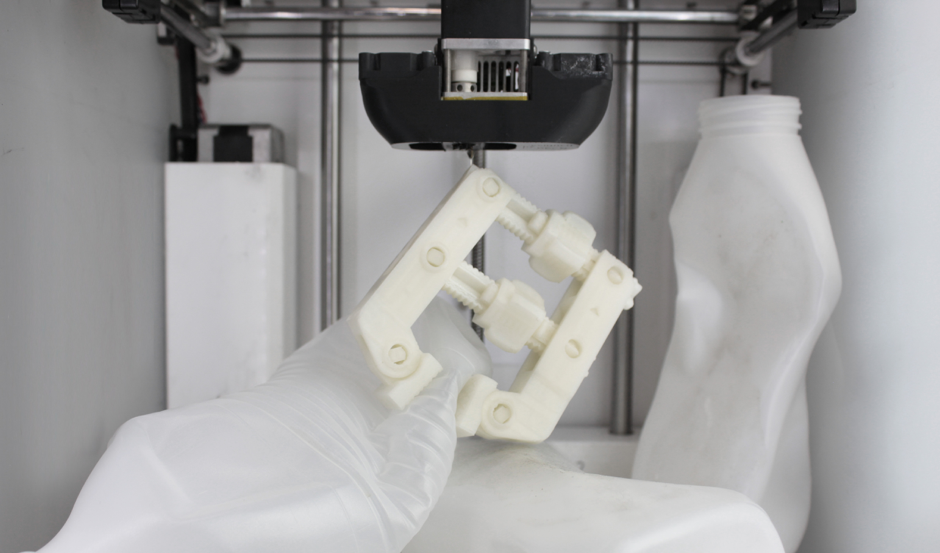

Featured image shows a recycled filament spool with empty yoghurt pots and examples of what can be printed from it them. Photo via Refil.