St Georgen, Germany-based 3D-LABS is a rapid prototyping service founded in 2009, which has been one of the first to widely publicize its adoption of Prodways MOVINGlight (Scan LED) technology, along with its SLA and MJM manufacturing capabilities. Adoption of this SLT technology as early as 2011 allowed the company to build a significant experience in working with Prodways’ unique materials capabilities, so much so that 3D-LABS is now even producing and testing its own resins.

These currently include their own LED.A resin and are now in the process of adding a new LED.W resin which may be one of the most interesting resins materials yet. Thanks to Prodways’ unique capabilities, this new resin includes Shape Memory Alloy (SMA) particles, which enable it to do exactly what the name says: revert back to its initial shape whenever this is modified.

The definition of Shape Memory Materials includes several different products that differen significantly. Nylon is a shape memory polymer in that it flexes right back to its original shape, while shape memory alloys can be more surprising. In some cases, both Shape Memory Alloys and Shape Memory Polymers can retain more than one shape. In this case, the integration of a Shape Memory Alloy in a 3D printable photopolymer yields a very interesting effect.

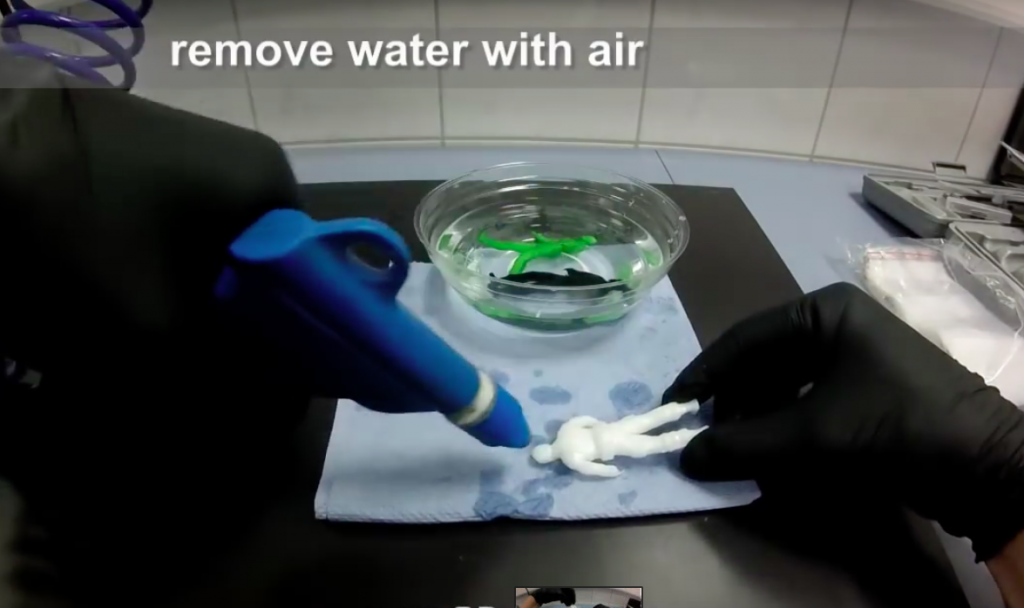

As the video shows, the resin 3D printed figures are heated and their shapes modified by a 3D-LABS team member. As the figures are cooled in water and dried, they now retain their new shape, with the legs twisted together or spread apart. When the figures are heated up again they revert back to their original shape and do so with extreme precision. In the video, the distance between the feet is compared and it is, once again, identical.

It is not entirely clear what the possible uses for this new material may be and 3D-LABS itself is asking the public to contribute ideas. Current uses for “traditional” Shape Memory Alloys include bone repair, fire prevention (valves that shut down in case of excessive heat), eyeglass frames, tubing, wiring, and ribbons. These are all very obvious fields for further 3D printing exploration.