Consolidation in the 3D printing industry continues, with news that 3D Hubs have acquired Romainian 3D model optimisation service Printivate. The details of the partnership have been kept private, but it sees Adrian Muresan, founder and CEO of Printivate, joining 3D Hubs team in its Netherlands office, in Amsterdam, as leader of Research & Development.

We’ve all been in that position where a print doesn’t turn out quite as expected. Ordering a poster from eBay finding it only to be printed on multiple sheets of paper from some desktop printer, or those promo stickers and business cards where the text is a little off. Printivate is a service that ensures such things don’t happen when 3D printing CAD models. Having just joined forces with the online 3D printing platform 3D Hubs, Printivate is to become integrated within 3D Hubs’ services, enhancing the quality control and turnaround time provided by the company.

“Our goal is to build the most efficient 3D print solution for professionals working in design and manufacturing,” said Bram de Zwart, CEO of 3D Hubs. Muresan of Printivate added that they have “developed advanced computational software that allows 3D Hubs to simplify and automate this process. The automation will lead to faster turnaround times, lower failure rates, less handling and higher quality prints throughout the platform.” The changes to 3D Hubs’ service are expected to be made before the year is out – presumably just in time for the festive season.

What are the benefits?

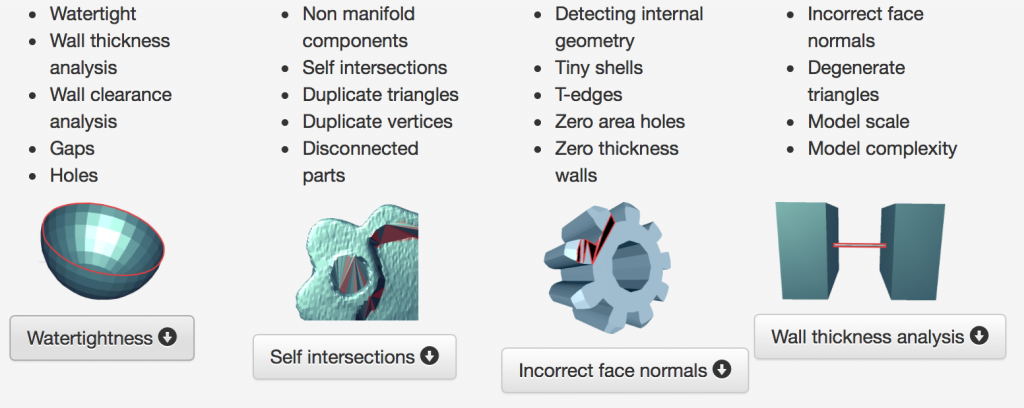

A Printivate 3D ‘printability check’ reviews 3D models for four main discrepancies:

- watertightness;

- self-intersections within the geometry of the design;

- incorrect face normals that cause holes in a 3D printed object;

- and wall thickness that determines the stability of an object.

The service can also reduce the complexity of a 3D model without compromising build quality, add hollows to products to save on material cost and the time taken to 3D print an object.

The products offered by 3D Hubs can be produced in all manner of additive manufacturing materials from basic PLA, to industrial standard metals, and has an average turnaround time of 48 hours. The way 3D Hubs does this is by outsourcing print requests to a database of people who own 3D printers. With a distance between the customer’s needs, the designer, and the 3D printer, having a Printivate system in place will serve to streamline these connections and take 3D Hubs’ service to the next level.

2016 has been a great year for 3D Hubs so far. In August they received a $7 million boost in Series B funding, and with this partnership, they are entering into a promising 2017. Coming up later today, 3DPI has an exclusive interview from 3D Hubs CEO Bram de Zwart giving further detail on the partnership.

Featured image is a screenshot from 3D Hubs’ Youtube video ‘Where 3D prints are made’. It shows a meshed globe produced via vat photopolymerisation.