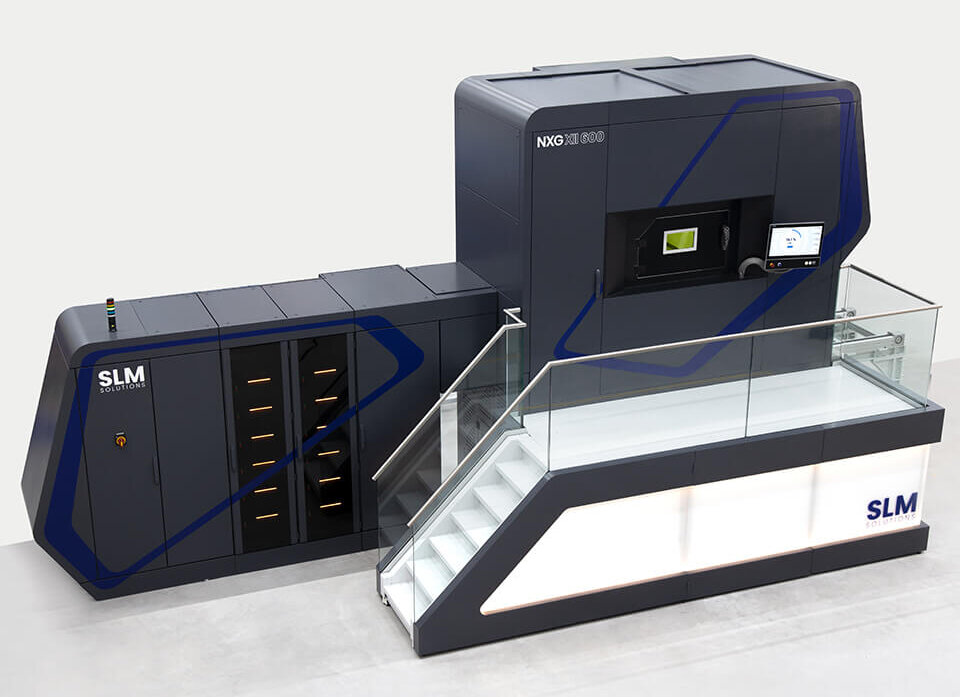

German metal 3D printer manufacturer SLM Solutions has launched a powerful new system called the NXG XII 600 at the Formnext Connect trade show.

SLM’s large-format machine comes equipped with twelve 1 KW lasers that can operate simultaneously, making it 20 times faster than the firm’s own single-laser SLM 280. The NXG XII 600 has been custom-designed to mass produce large parts, and its enhanced size and speed could open up serial production applications for the system in the automotive and aerospace sectors.

“What we deliver here with 12KW of installed laser power is truly ground-breaking and a major step forward, not just for additive manufacturing, but for manufacturing in general,” said Sam O’Leary, COO of SLM Solutions. “For the first time in the history of additive manufacturing, you can have true serial production fully integrated into your supply chain.”

“The NXG Xll 600 is a revolution in industrial manufacturing.”

SLM’s metal 3D printing solutions

Based in Luebeck, Germany, SLM Solutions is a specialist in developing and producing Selective Laser Melting (SLM) additive manufacturing systems. The company’s current machine portfolio includes the SLM 125, SLM 280, SLM 500, and SLM 800 systems, and it has now added the NXG XII to its commercial offering.

SLM had failed to hit its revenue targets until last year, but it has since rebounded and reported record growth in Q1 2020, followed by a 37 percent revenue increase in its most recent financials. The company’s sales successes can somewhat be attributed to the development contracts it has signed with a range of aviation and automotive manufacturers.

Working with the aerospace conglomerate Honeywell earlier this year, for instance, SLM produced a parameter set for 3D printing aluminum F357 with its systems. The firm has also partnered with the space-faring company Orbex, and French supercar manufacturer Bugatti, to develop critical components for their rocket engines and brakes respectively.

Building on the experience it has gained from working with its automotive and aerospace partners, SLM is now targeting these markets, with its new NXG XII 600 large-format rapid manufacturing system

The NXG XII 600 and mass manufacturing

SLM is aiming to “push productivity to the next level” with its latest 3D printer, which features twelve optimized 1 KW lasers, that enable it to provide users with “unrivaled” build-up rates. Designed from the ground up for mass production, the new system includes a whole new optics system that according to the company at least, makes it “the most compact on the market.”

The NXG XII 600’s optical setup is based around a laser scanning system that has been tailor-made to fit its build area and allows for a large amount of overlap during the printing process. Each of these twelve optics features a double lens system with ‘zoom functionality,’ which enables clients to choose between different spot sizes in the focal plane.

This enhanced lens system acts to not only boost the machine’s build-up rates to 1000 cc/h, but to yield a higher volume of parts from a single print job, which lowers the overall cost-per-part for users. SLM’s new system also features a large 600 x 600 x 600 mm build envelope, enabling the production of large-format parts, at faster speeds than were previously possible.

In addition to enhanced optics, the NXG XII 600 has been designed with a new thermal concept that minimizes drifts and enables users to print parts that are “stitched” together with all twelve lasers. Operating the machine has been made easier too, and its new UI software is focused on delivering productivity by reducing any initial training that may be required.

To facilitate the integration of the NXG XII 600 into existing setups, SLM has fitted it with an automatic build cylinder exchange and included both external preheating and depowdering stations. Clients can also choose between two tailored powder handling options in the form of gravity or vacuum-based system, to maximize throughput by reducing any downtime.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows SLM’s new NXG XII 600 3D printer. Image via SLM Solutions.