That’s what a New Jersey college student did, and its making that usual hefty price tag feel all the more painful…

One quick word of warning though, don’t try this at home!

To give a little context on what kind of orthodontic care we’re talking about, Twenty-three-year-old Amos Dudley used 3D printing to create his own sets of braces. Since the age of metal ‘train-tracks’, these contraptions fraught with ulcer making, food trapping edges and corners have made way for a new kind of brace which has really taken off in recent years. These ‘invisible’, clear plastic braces have helped to limit the pain, discomfort, staining problems associated with metal braces. They’re even removable, which is both a blessing and a curse, and also have some limitations in what they can do during treatment. These braces come at quite a cost, a cost Dudley couldn’t afford. He’d had braces in the past, though unfortunately neglected them, leaving him with a half-done job which soon reverted back to the crooked smile which bugged him so much.

“I felt bad about my teeth- in part because they were crooked, but also because they were a reminder that I had neglected them,” Dudley said to Buzzfeed in an interview. “I felt like I had wasted the money my parents spent on my braces.” he said.

However, as much as his college education limited his financial situation, it certainly didn’t limit the resources to solve the problem.

After lots of research, and seeing many failed attempts of ‘DIY Orthodontics’, Dudley set himself to work.

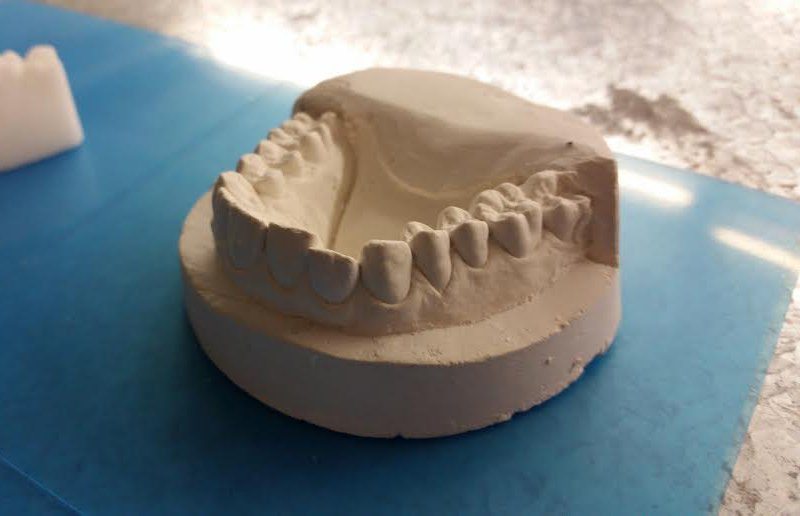

He first took an impression of his teeth using alginate, the same was a dentist takes impressions of a patients teeth.

Next he took a cast using the mold, and cleaned up any messy parts.

This is where 3D technology over.

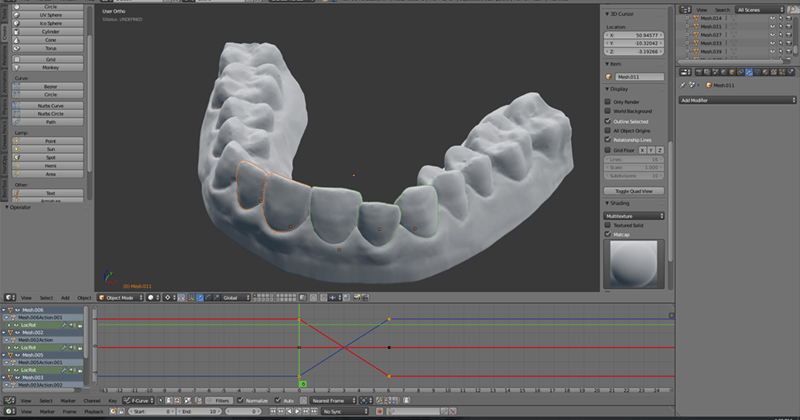

Using a NextEngine machine, Dudley was able to create an accurate 3D scan of the cast. There are now methods to scan teeth from a patients face, though in this case, it was easier to scan a cast.

He then separated every tooth from the 3D model and worked out a pathway for each tooth, ending up with them all being straight. The distance for each tooth pathway was then broken down to a maximum tooth distance per aligner brace, and an stl file was created for each step.

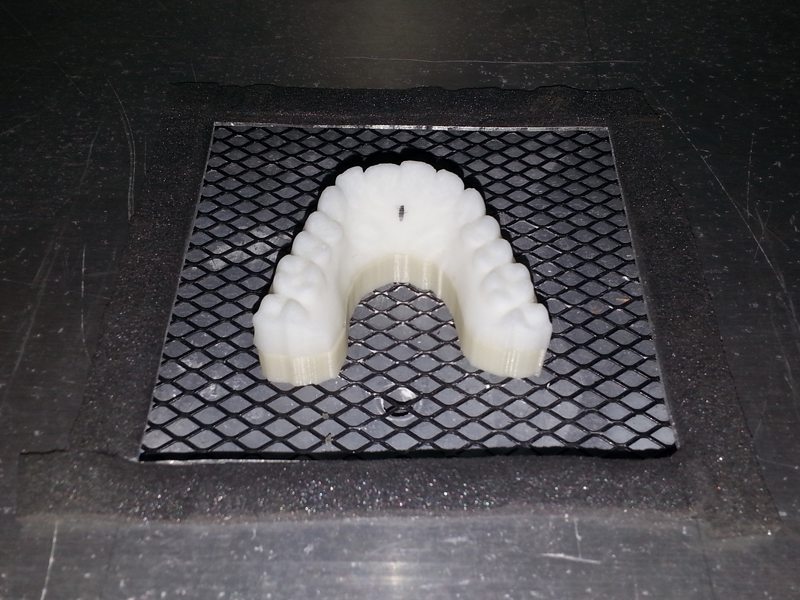

Each stl file was then printed to create physical models to form the aligner braces over.

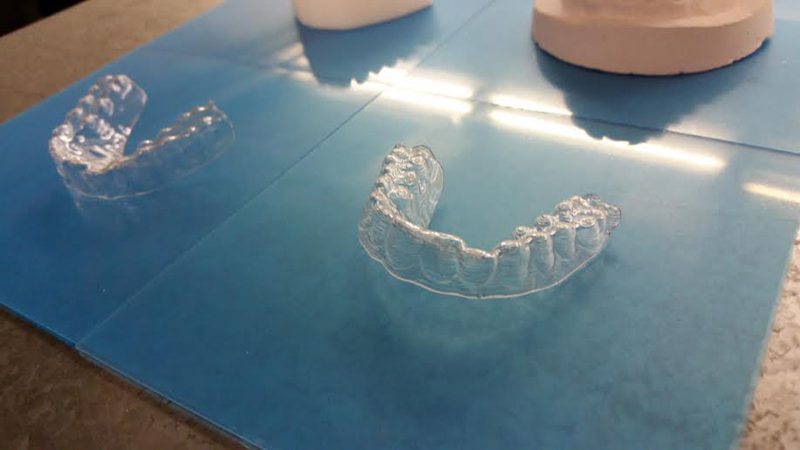

The aligners themselves were then vacuum formed over the 3D printed models in plastic that was sourced from ebay.

Excess plastic was then trimmed, and Dudley started using the aligners. And here’s the results!

Despite the amazing results, there is a reason why it takes so many years for an orthodontist to gain their qualifications. There are many risks when taking the plunge to fix things in an area where you don’t know every detail, and Dudley is one of very few that has managed with a success he is happy with.

So, unfortunately this doesn’t mean you can start off your own-brand of ortho-care products and treatments, though many, including some orthodonists will admit his project was rather impressive!