Zortrax, a Polish 3D printers and materials manufacturer, has introduced biocompatible resins for dental applications, such as bridges, crowns, and surgical guides.

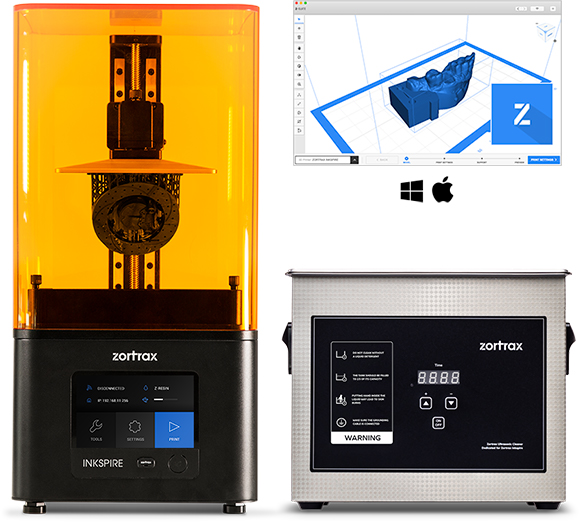

The newly released materials are compatible with Zortrax’s latest UV LCD 3D printer, Inkspire, which the company claims is eight times faster than SLA and DLP 3D printers available on the market.

From FDM to LCD

Founded in 2013, Zortrax manufacturers a range of extrusion-based 3D printers, which includes the award-winning M200, M300 Plus and M300 Dual. The Inkspire is a more recent expansion into resin based 3D printing.

According to the company, one of the barriers against the wider adoption of 3D printing is the difficulty of setting up 3D printers. For this reason, Zortrax emphasizes “plug in and play” philosophy. To simplify the 3D printing process for its users, Zortrax sells its machines as a full suite of hardware and software, for example, Zortrax machines process the 3D data in a ‘Z-CODE’ which is prepared in the company’s own slicing software.

In addition to FDM printers, Zortrax also manufacturers a wide range of filaments, which include PLA, ABS, and elastic materials.

After succeeding with FDM/FFF technology Zortrax introduced the Inkspire 3D printer, capable of producing models as small as 50 x 50 x 25 microns (XYZ). A helpful feature of the Inkspire system is the ‘on-the-fly’ print setting options. This allows a user to change the printing parameters of an in-progress job via Inkspire’s touch screen.

Although Zortrax produces its own range of materials for Inkspire, the UV LC 3D printer also supports third-party resins, provided they are curable at a wavelength of 405nm.

Digital dentistry

In the recent past 3D printing in the dental industry has grown to be a billion dollar market. Part of the reason for the popularity of resin printers in the dental sector is that they are able to capture details very precisely. Some of the 3D printers which have been successful in the dental arena are NextDent 5100 by 3D Systems, Form 2 by Formlabs, and the full-color polyjet 3D printer J720 by Stratasys.

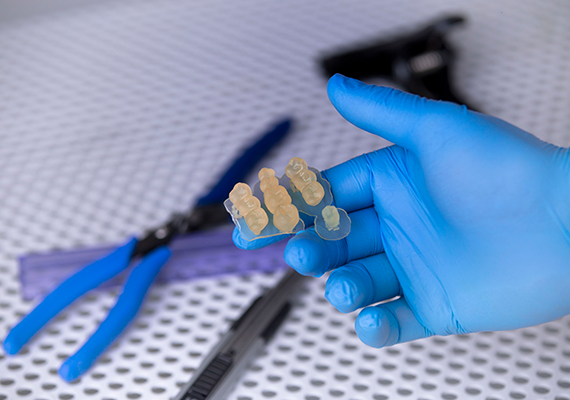

Zortrax hopes to make an impact on the dental and medical sector with the introduction of its new biocompatible materials named Raydent Crown & Bridge and Raydent Surgical Guide. The Raydent Crown & Bridge is an abrasion resistant Class II material, which is classified as safe for thirty-day contact with human tissue.

On the other hand, the translucent Raydent Surgical Guide is classified as Class I can be used for temporary tissue contact where temporary is defined as enough time for a surgical procedure to be carried out.

To learn more about how 3D printing is transforming the dental sector, subscribe to our 3D printing newsletter. For live updates follow us on Twitter and Facebook.

We also have jobs in the industry, visit 3D Printing Jobs to find out more.

Featured image shows dental samples 3D printed using Raydent Crown & Bridge Resin on Zortrax’s Inkspire. Image via Zortrax.