3D Systems has launched the NextDent 5100 3D printer, a Figure 4 powered additive manufacturing system for the dental market.

Just over a year has passed since 3D Systems acquired NextDent. Speaking at the time, the combination of NextDent’s specialist dental materials, and 3D Systems recently announced Figure 4 3D printing platform was described as, “a strategic foothold in the multi-billion dollar digital dentistry opportunity.”

During a conversation earlier today with Vyomesh Joshi (VJ), the President and CEO of 3D Systems explained that, “dentistry is the critical market for 3D Systems”. With the company’s share price currently around $10, investors will be hoping the CEO is right.

In the 3D Systems’ favor is the size of the global dental market, forecast to reach 37 billion U.S. dollars by 2021. Digital dentistry as a subset of this market could rise from $2.5 billion in 2018, to $4.6 billion in 2021 according to Smart Tech Markets. With an 18% CAGR, that market would be worth nearly $10 billion in 2027.

The key to accessing this opportunity, according to VJ, is offering dental professionals a full range of services. While a number of 3D printing enterprises can address stand-alone applications, for example denture frameworks or surgical guides, VJ says meeting the full spectrum of customer needs is key.

Rik Jacobs has over 20 years experience in dental, with the past 10 years also covering 3D printing. Previously employed at NextDent, Jacobs is now VP, General Manager Dental at 3D Systems. I asked him how 3D Systems differentiates itself from enterprises such as Carbon and Stratasys in the dental market. He explained that some of difference comes from having, “established an application team and a dedicated network of resellers,” in the dental sector. This ensures customers receive, “proper training, service and support.”

This experience does add an element of differentiation to the 3D Systems dental offering, however it is important to note that traditional dental providers are not standing still. For example, in June 2017 Straumann bought a 35% stake in German 3D printer manufacturer Rapid Shape.

3D Systems does also have the experience of producing 300,000 dental aligners on a daily basis – more than 100 million annually.

3D Systems launches NextDent 5100

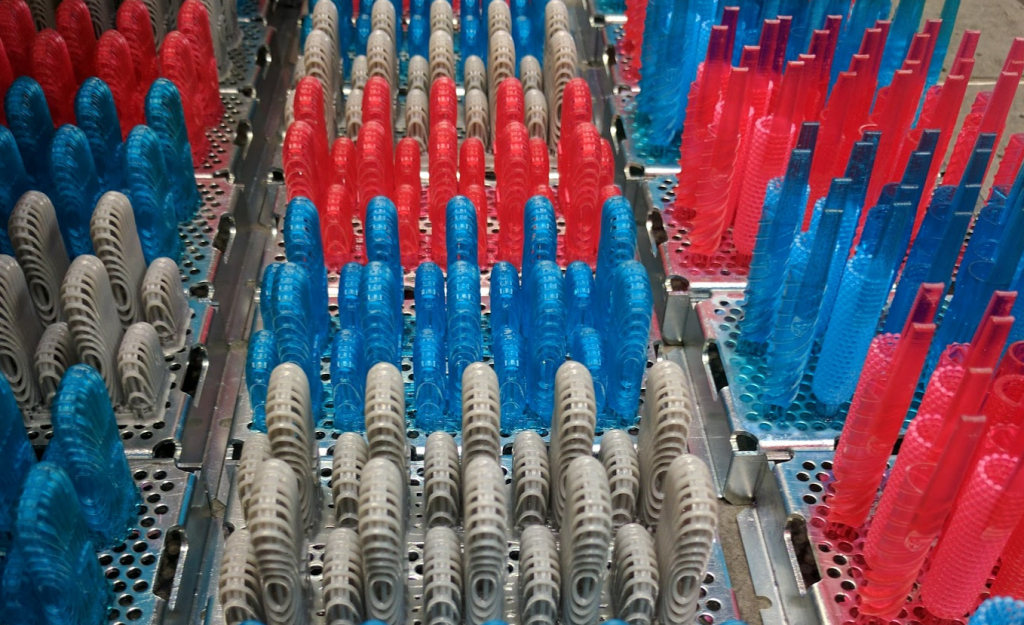

Speaking from LMT Lab Day Chicago 2018, 3D Systems revealed their latest 3D printer for digital dentistry, the NextDent 5100. Complementing the launch the company also announced 18 new NextDent resins, bringing the full portfolio to 30.

The Figure 4 SLA 3D printing engine powers this new NextDent 5100 dental 3D printer. According to 3D Systems, the 3D printer, “out-performs similar competitive offerings with 4x the speed [and] provides customers up to 90 percent cost savings.” Designed for high-speed 3D printing of dental devices and fixtures, the 3D printer can deliver more “precise results than conventional manual production techniques.”

3D Systems describes the enlarged portfolio of 30 NextDent dental materials as “clinically-validated” and says this is the “largest number of unique resins available, facilitating full customization of dental devices.” Rik Jacobs explained to me how the process for CE or FDA certification requires biocompatibility studies, the creation of technical files showing every step from scanning to final use and that substantial testing is conducted at their Netherlands’ R&D facility.

The company also works closely with academic experts in the dental education sector. Specifically the materials are “certified in accordance with medical device directive 93/42/EEC, [and] listed at the FDA.” Certification in other regions is also underway.

In terms of predictability and accuracy the, “end-to-end digital workflow also provides higher and more predictable uptime, with a significant reduction in risk for the operator.”

Regarding price, when the NextDent 5100 becomes generally available in the Summer of 2018 it will be priced below $10,000 (US)/€10.000 (EU Countries). VJ was quick to point out that the Carbon system is, “$40k per year.”

“We offer the industry’s widest range of regulatory-approved 3D printing materials and technologies that allow dental labs and clinics of every size to drive precision, productivity, and efficiency at a reduced cost for a wide range of dental applications,” said VJ.

Pre-orders for the NextDent 5100 will commence in the second quarter of 2018.

According to Jacobs a 3D Systems digital dentistry customer might be “a 1 or 2 person outfit, or an organization with thousands of employees,”

As part of the launch, 3D Systems provided feedback from 3 beta partners with experience of the new dental 3D printing systems.

Esteban Ponce, president, Danso Dental Lab (San Diego, CA), said “The new NextDent 5100 fits the size and workflow of our lab perfectly. Through the choice of materials, quality, and speed of the system, we can reduce our reliance on milling centers for manufacturing and reduce our costs. When we worked with a milling center to produce models, each one cost us $30. By employing the NextDent 5100 solution and producing the same model in-house, we realized a 90% reduction in cost.”

Sebastiaan Cornelissen, chief executive officer, Core3dcentres (Holland & Cordent, The Netherlands, said, “It’s the freedom to produce any shape in significantly less time and at a much lower cost than was possible with milling. With 3D Systems’ new NextDent solution which includes both the printer and materials, Core3dcentres Holland and Cordent will be able to improve productivity and patient care.”

In November 2017, 3D Printing Industry visited the 3D Systems Healthcare Technology Center in Littleton, CO where the FabPro 1000 3D printer was on display. Initially the FabPro 1000 was marketed for jewelry and engineering applications, but now has “expanded capabilities to address dental indications.”

General availability of the FabPro 1000 3D printer is planned for Spring 2018, with dental materials availability planned for Summer 2018. Pricing for the SLA 3D printer will be below $5,000 (US)/€5.000 (EU Countries). 3D Systems’ 3D Sprint software is included in the price. Currently the FabPro 1000 is undergoing optimization for, “compatibility with select NextDent biocompatible materials for specific dental applications, starting with surgical guides and orthodontic and denture models.”

Other components of the 3D Systems dental portfolio include, the ProJet MJP 2500 MultiJet solution for dental models using tan material for easy detail visualization; ProX® 800 stereolithography technology for dental models, patterns, and drill guides batch production; the ProX DMP 100 Dental and ProX DMP 200 Dental metal printers for manufacturing high quality, metal dental prostheses; and Dental Manufacturing and Design Services supported by the company’s Customer Innovation Center (Leuven, Belgium).

Accessing the substantial addressable market opportunity does of course come with challenges. Pressure points include proper training, an area Rik Jacobs says the industry is making progress in. Jacobs notes that in the Netherlands some 5th year dental students now receive training in how to implement 3D printing.

In concluding our interview for the day, VJ tells me, “this is just the beginning of a revolution”. What might the other key applications for the Figure 4 platform be? “Stay tuned,” he says.

Is 3D Systems’ Figure 4 platform a breakthrough 3D printing technology? Let us know and make your nomination in the 2018 3D Printing Industry Awards now. Nominations close in one week.

Subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Want to win a 3D printer? Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition, enter now.