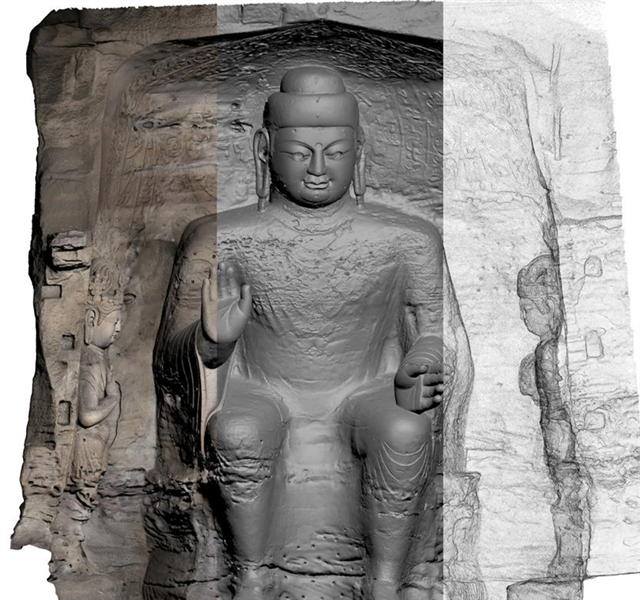

Conservationists from the Yungang Grottoes Research Institute and Zhejiang University (ZJU) have created movable replicas of its 3D printed ancient Buddhist statues.

The Yungang Grottoes, a UNESCO world heritage site located west of Beijing near the city of Datong, contains over 50,000 statues, carved into golden sandstone cliffs and displays the origins of Chinese Buddhist art.

The full-size reproduced grotto is 14 meters long, 11 meters wide, nine meters high and weighs less than 5 metric tons and is said to be the world’s largest movable grotto printed by 3D technology.

Conserving Chinese Buddhist art

Last year, replicas of the three statues from the Yungang Grottoes, measuring six, ten and six meters respectively, were scanned and 3D printed after they were determined to be at risk from weathering. Following this, the statues were displayed in the eastern coastal city of Qingdao.

Nonetheless, due to the time taken to install the displays and its weight, the replicas were not able to be moved. Recognizing this, a team from Zhejiang University, produced a lightweight version of the 3D printed statues that can be divided into various parts and assembled within a week.

The team collected high precision 3D data and kept error within two millimeters, then used additive manufacturing to print the pieces of the statutes in approximately six months. According to Zhang Zhuo, Head of the Yungang Grottoes Research Institute, the movable statues have “passed experts’ tests” and will be added to future exhibition tours along with the institute’s other cultural relics.

The three ancient Buddhist statues, which are depicted with Chinese and Western musical instruments, derive from the original cave No. 12, also called “Cave of Music,” in the Yungang Grottoes which represents the highest artistic level of Yungang.

“We plan to color it with mineral pigments before the end of this year. In this way, the replica will maintain its original size, texture, and color,” added Zhuo.

Zhejiang University and 3D printing

Zhejiang University has demonstrated its understanding of 3D printing technologies through its innovative research. Earlier this year, a group of researchers from the university proposed a new method of 3D nanofabrication by combining ice and electron beam technology to print large-scale metal parts.

Prior to this, Zhejiang University, in collaboration with the University of Birmingham and Stockholm University, identified ultra-mechanical properties in a popular 3D printable steel alloy which can potentially “program” steel molecules to make high-strength, ductile products, for use high-performance applications.

Catch up with the latest in additive manufacturing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the 3D printed Yungang Grottoes. Photo by Zhang Xingjian.