Inkjet 3D printer developer Xaar has claimed that its Ultra High Viscosity (UHV) technology “is opening up new possibilities” at product packaging facilities across multiple sectors.

Specifically, the firm believes the “unbeatable capability” of its UHV-driven ImagineX to jet fluids with viscosities of up to 100 centipoises (cPs) in a single pass, is allowing users in the packaging sector to “free their creativity.” According to Xaar, the large particle processing abilities of its machine make it ideal for producing high-opacity, wide-gamut parts, thus it now enables designers to give their labelling more zing.

“Whereas previously, inkjet printheads have typically only been able to jet fluids of around 8 to 12 cP, our technologies enable printers to jet much higher viscosities,” explains Graham Tweedale, GM of Xaar’s printhead business unit, “thus achieving a wider colour gamut and unparalleled opacity, [that] can be used to print an extensive range of special effects.”

Xaar’s printhead portfolio

Established in Cambridge, UK, Xaar prides itself on being the world’s leading independent manufacturer of piezo-based drop-on-demand inkjet technologies. The firm puts its inkjet expertise into practise by developing industrial printheads, with the ability to consistently deposit fluids in precise volumes, for customers in the industrial packaging, ceramic or glass decoration and outer case coding sectors.

In the past, the Xaar has also dipped its toe into the High Speed Sintering (HSS) market, setting up a dedicated 3D printing hub in 2016, before going on to found Xaar 3D alongside Stratasys. Until recently, Stratasys only held a 45% share in the venture, but it took full control of Xaar3D in October as part of its plans to integrate HSS into its new H Series 3D printers, having launched the H350 earlier this year.

Following its sale of Xaar3D, Xaar’s offering largely leans on its portfolio of printer add-ons, printheads, materials and related services, with its newest product being the ‘Irix’. Launched in September 2021, the firm’s latest printhead is capable of 3D printing and fluid dispensing inks ranging from solvent-based materials, to those needed for industrial manufacturing.

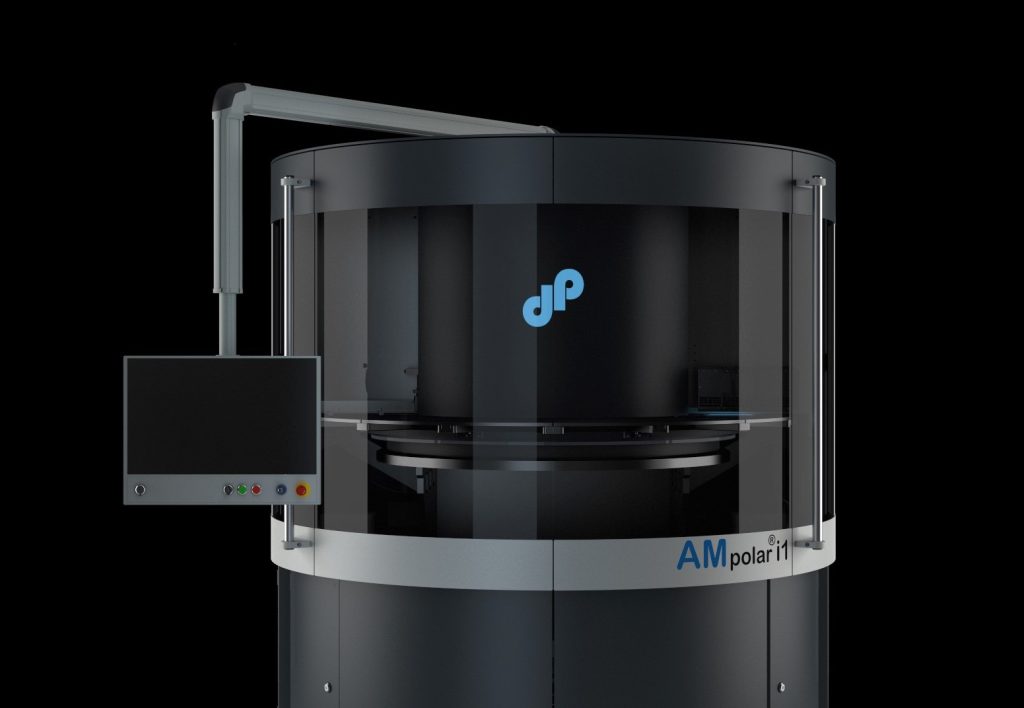

To bring its technologies to market, the company has often packaged them with third-party 3D printers such as the AMpolar i1, which comes fitted with Xaar 1003 printheads. The firm has also introduced a 5-step material evaluation service that’s designed to help those clients seeking to jet high-viscosity fluids, and given Xaar’s recent spike in use-cases, the initiative now appears to be paying dividends.

Ultra High Viscosity in-action

Launched in 2019, Xaar’s latest bulk printhead platform, ImagineX, is capable of printing all ink types at temperatures of up to 200oC, thus it’s designed to serve as a basis for the firm’s entry into new verticals for years to come. The system is powered by UHV, a technology in which inks can be jetted at an unprecedented level of viscosity to rapidly and efficiently create parts, often for promotional applications.

In effect, the ImagineX is able to achieve this by processing larger particles than ordinary inkjet systems, which contain higher amounts of pigment, and yield more vibrant colors as well as clearer blacks and whites. The machine is also capable of printing onto curved surfaces, making it perfect for direct-to-shape packaging production, while it can be used to add high-build varnish embellishments too.

Utilizing this feature, adopters are able to add textures to labels, whether that be for visual impact or functionality. For instance, UHV allows users to deploy inks that resist cracking to create flexible labels, while the technology enables braille and tactile warnings to be added to packaging as well, in effects that can only usually be achieved via screen printing.

Compatible with its Nitrox, 2002 and 50x series printheads, Xaar says that since launch, the technology has already “demonstrated the significant difference” inkjet-based production can have when used to create high-impact digital labelling and packaging at scale.

“We are already seeing how Ultra High Viscosity technology is opening up new possibilities for Xaar in a number of applications,” added Tweedale. “After many years of requests from clients to be able to print higher molecular weight photopolymers to increase resistance and flexibility for printed materials, our Ultra High Viscosity technology has realized this capability, truly unleashing the power of inkjet.”

Is inkjet 3D printing hotting up?

Although the multi-material inkjet space continues to be dominated by Stratasys’ PolyJet and 3D Systems’ MultiJet technologies, these are largely based on 2D inkjet printheads. As a result, machines powered by these technologies rely on relatively low viscosity resins, thus there remains a gap in the market for a system able to deposit high viscosity materials at an industrial throughput.

One such company seeking to break the inkjet 3D printing mold is Quantica, which launched its industrial-grade material jetting T1 Pro machine at Formnext 2021. Based around the firm’s Extreme Viscosity Jetting technology, the system is said to be capable of depositing liquids up to 15 times more viscous than existing multi-material jetting systems, enabling the fabrication of much higher-strength parts.

In more research-oriented applications, Zdalny Serwis is also looking to shake things up in the world of inkjet 3D printing, with its Duroplast Reactive Inkjet Printing or ‘DRIP’ approach. In essence, the technology involves colliding ink droplets in mid-air to form parts, and the company has now begun working on a means of integrating FDM printable supports into a fully-functional prototype DRIP 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a translucent print produced using Xaar’s Ultra High Viscosity technology. Photo via Xaar.