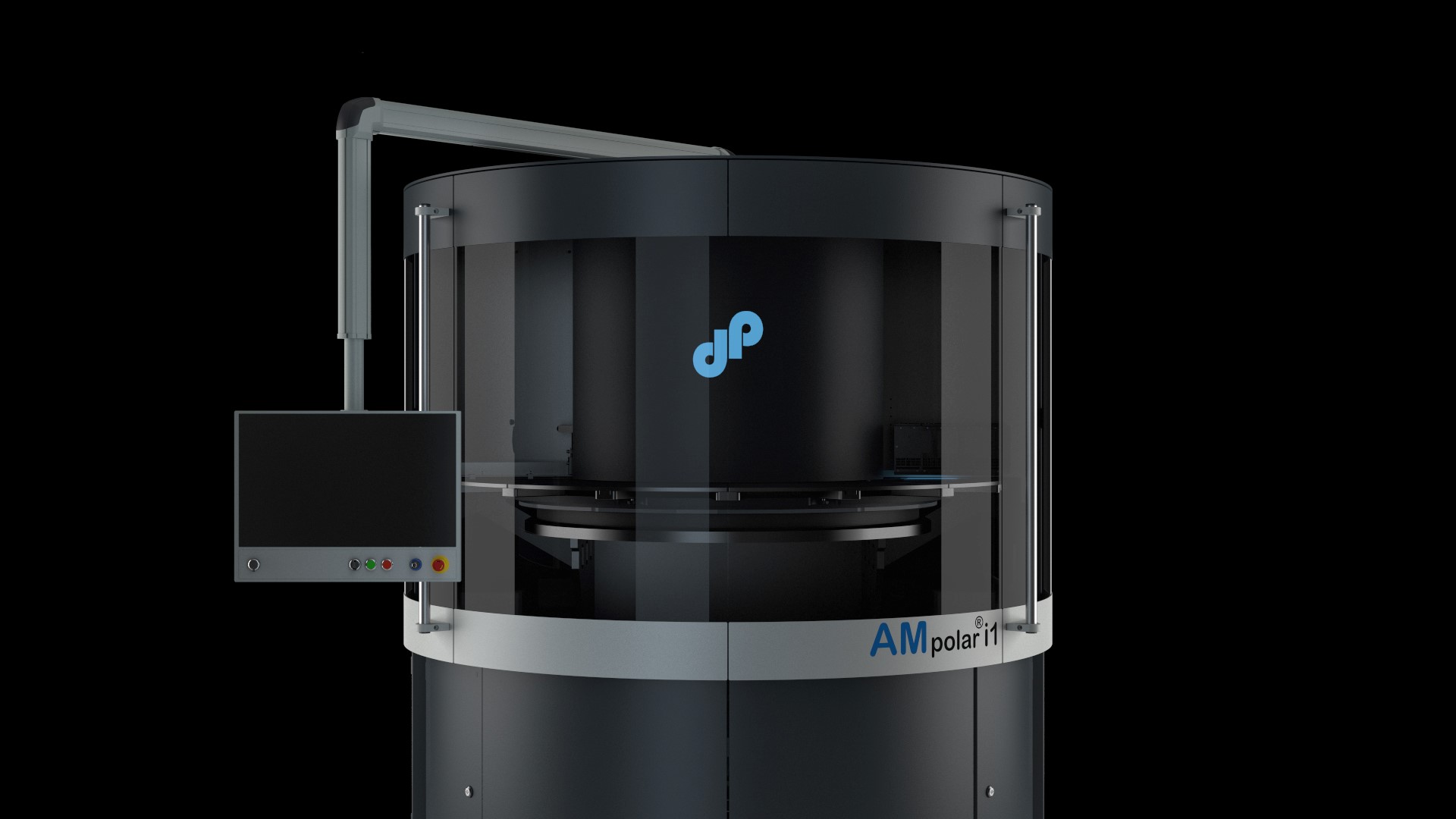

Industrial 3D printer manufacturer dp polar will unveil the latest addition to its range, the AMpolar i1, at Formnext 2021 next week.

The firm has once again opted for 1003 printheads from inkjet printhead developer Xaar to kit out its new machine and enable the mass production of 3D printed parts on an industrial scale.

Based on dp polar’s patented single-pass 3D printing process, the AMpolar i1 will reportedly facilitate build volumes of up to 240 liters across its continuously rotating print platform, while achieving an output that traditionally would have required multiple conventional 3D printers.

“The AMpolar i1 delivers all the production benefits of the AMpolar i2, but at a scale and in a format that facilitates businesses in their early stages of exploring what is possible in mass production 3D printing,” said Florian Loebermann, dp polar’s Managing Director.

“Xaar’s printheads have proved invaluable in unlocking the full potential of our systems, and the openness of the Xaar team to support our innovations is helping to establish 3D printing and additive mass manufacturing as a practical reality in the volume production of parts for many businesses.”

dp polar’s single-pass printing technology

The AMpolar i1 leverages dp polar’s patented single-pass material jetting 3D printing process, which is based on a rotating print platform. The rotating platform allows the firm’s technology to work continuously to facilitate the uninterrupted printing of parts from the first to the last layer.

dp polar develops industrial 3D printing systems for use within a variety of industries, including the automotive, aerospace, mechanical engineering, and consumer sectors.

dp polar launched its first 3D printer at Formnext 2019, the AMpolar i2, in partnership with German chemical group ALTANA AG, which had previously acquired a stake in the company in 2017. The machine’s large build volume, rotating print platform and single-pass printing combination opened it up to industrial series production of additively manufactured parts.

The firm has worked with Xaar over several years for the use of its printheads, which are key to maximizing the scalability and productivity of its single-pass printing technology.

Achieving industrial-scale production with Xaar printheads

Best known as a manufacturer of inkjet technologies, Xaar also has a background in high-speed sintering (HSS), having opened a dedicated 3D printing hub in 2016. Just last month, industrial 3D printer manufacturer Stratasys took full control of Xaar after acquiring all remaining shares in the company. The two had worked together to integrate selective absorption fusion (SAF) technology into Stratasys’ H Series machines to accelerate production-scale 3D printing.

Xaar’s ultra high viscosity technology enables its printheads to jet fluids up to 100 centipoises (cP) in a single pass, a capability leveraged by dp polar’s new AMpolar i1 printing system. In particular, the printer is equipped with the Xaar 1003 printhead which combines speed and reliability with the capacity to jet a multitude of fluids at increasingly high viscosities.

The printhead therefore enables the AMpolar i1 to jet parts at volume and deliver 3D printed objects on an industrial scale, while opening up a range of new applications.

The AMpolar i1 is a more compact version of the AMpolar i2, enabling build volumes of up to 240 liters across its rotating print platform, with a build volume of just under one square meter. The machine prints layer of between 4-25µm and can achieve a resolution of up to 720 x 720 x 5.000 dpi.

According to dp polar, the combination of its single-pass printing technology and Xaar printheads delivers scalability, productivity and agility to its production process. The machine reportedly achieves an output that would require multiple conventional 3D printers, and significantly more capital investment, to match.

“The innovative and agile AMpolar i1 firmly establishes the use of resin jetting as a truly practical and commercially viable manufacturing process,” said Gareth Neal, Xaar’s Customer Applications Manager for Advanced Applications, Technologies and Fluids. “With Xaar’s range of printheads including our unique Ultra High Viscosity Technology providing the speed, flexibility and reliability demanded, functional inkjet applications have never been more accessible, affordable or productive.”

Visitors to Formnext will be able to see the AMpolar i1 for the first time at dp polar’s stand in Hall 12.1. To keep up with all the news and launches at the show, make sure to tune in to 3D Printing Industry’s livestreams, taking place each day of the event, by subscribing to our YouTube channel.

Technical specifications and pricing

| Application technology | Material jetting |

| Build width | max. 280 mm (11.0 in) |

| Build area | 0.96m2 (10.3ft2) |

| Build volume | 240 L (8.5ft3) |

| Layer thickness | 4-25µm |

| Resolution (xyz) | up to 720 x 720 x 5.000 dpi |

| Productivity | max. 7 L/h (0.25 ft3/h) |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the AMpolar i1 3D printer. Photo via Xaar.