The 2019 3D Printing Industry Awards are less than two months away and we are on the hunt for this years trophy.

If you think you have a winning design then submit your idea for the chance to see it become the official trophy given out at this years award ceremony. If successful you will win an Ultimaker 3 3D printer.

Sponsored by Protolabs and hosted by MyMiniFactory the competition will close at midnight (GMT) on May 1st 2019.

The task is to design a trophy that truly embodies the possibilities of 3D printing, and Protolabs’ state of the art manufacturing capabilities. The winner will have access to the full capabilities of Protolabs, state of the art, additive manufacturing machinery.

With this in mind, you should design a trophy that will celebrate the unique capabilities of 3D printing, whilst pushing Protolabs manufacturing capabilities to the limit.

You will also receive your design made using Protolabs advanced manufacturing technology.

2019 3D Printing Industry Awards trophy design brief and guidelines

– Be designed to be made in two different materials, one part SLA and one part MJF

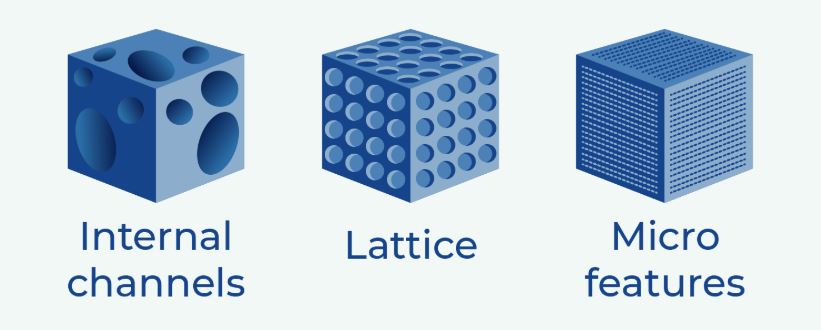

– Use internal channels

– Incorporate multiple features that are minimum 0.15-0.20mm in size (preferably in the same orientation) for SLA parts

– Have a minimum feature size for MJF parts of 0.75 mm

– Have a min/max trophy size of: 75x75x75mm/125x125x125mm

– Be optimised for SLA and HP’s MJF

Last year’s winner, Sruthi Venkatesh attended the Awards dinner and was a first time MMF designer, so the competition is really open to anyone.

Some tips

– Think about your design(s) in relation to the brief and how best you might best optimise it for 3D printing.

– Make sure you read all the design constraints and download all designer resources so as to ensure you are on the right track.

– This year, the company is also looking for unique designs that incorporate both SLA and MJF 3D printing techniques

– Once your design is approved, post it on twitter with the tags #3DPIAwards, @MyMiniFactory, @3DPrintIndustry, @Protolabs

Highlighting designers

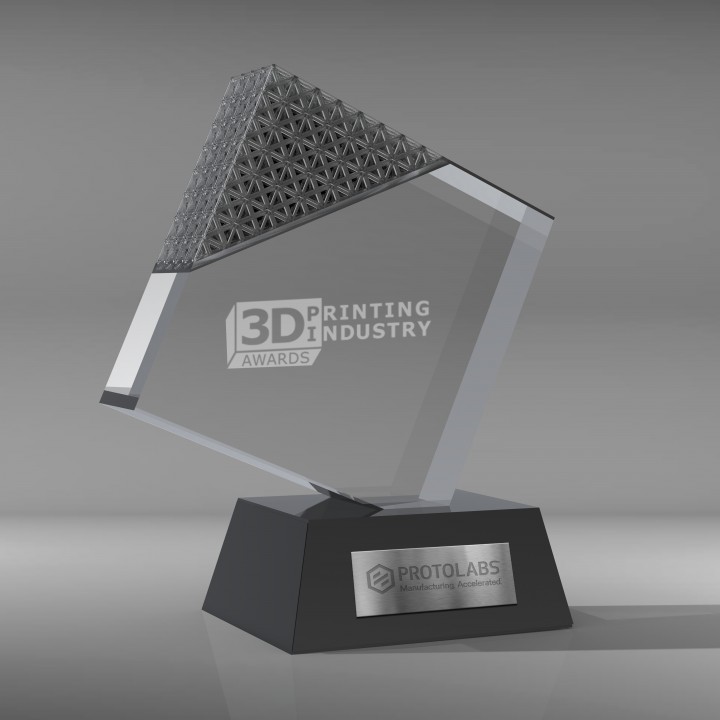

Levi Giesbrecht’s design that takes advantage of support-free powder-bed printing and the semi-translucent properties of MJF and SLA.

The 3 rings are actually 3 rotated stars, as to represent 3D printing. The central part, or as Levi calls it, the “support” is a pattern often generated by FDM slicers, another branch of 3D printing. The base has the general shape of a “D”. The letters on the front, “3DPI”, are the initials of the 3D Printing Industry.

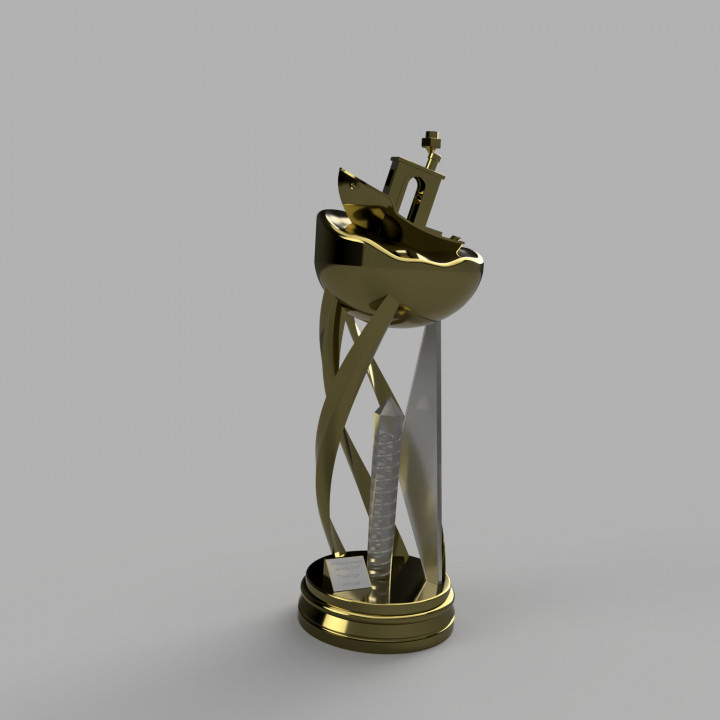

Tobias Reckinger’s Benchy themed design is made of multiple components. The main body will be printed with MJF while the other Parts are meant to be 3D printed using SLA. The SLA Parts will also be transparent.

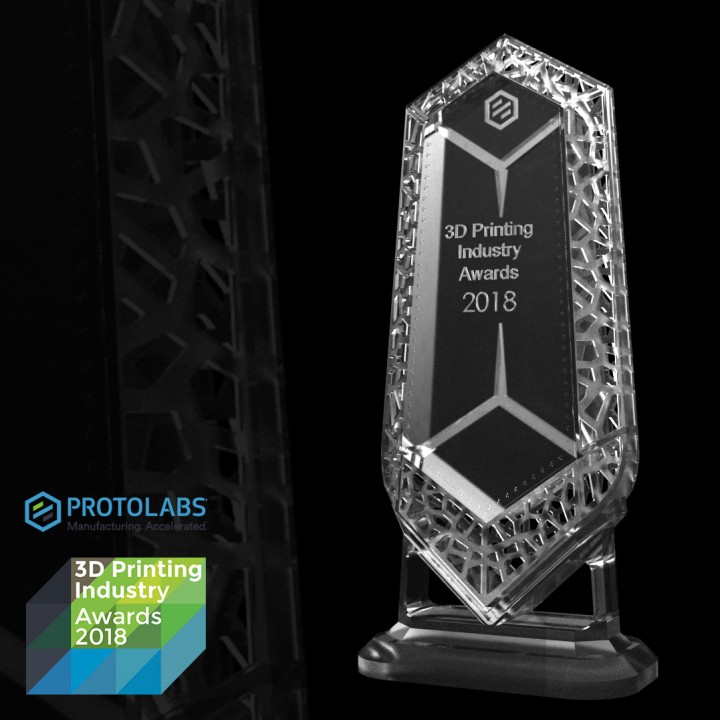

The evolution of the design competition

Here are some of the designs from last year we also admired.

The 3D Printing Industry Awards will take place on June 6th 2019 in London.

Please also remember to vote in the 2019 3D Printing Industry Awards. For more information on the latest trends in additive manufacturing subscribe to our 3D printing newsletter and follow us Facebook and Twitter.

We also have jobs in the industry, visit our 3D Printing Jobs board to find out more.