The 2019 3D Printing Industry Awards are now less than seven weeks away and we are still on the hunt for this years trophy.

If you think you have a winning design then submit your idea for the chance to see it become the official trophy given out at this years award ceremony. If successful you will win an Ultimaker 3 3D printer.

Sponsored by Protolabs and hosted by MyMiniFactory the competition will close at midnight (GMT) on May 1st 2019.

Highlighting designers

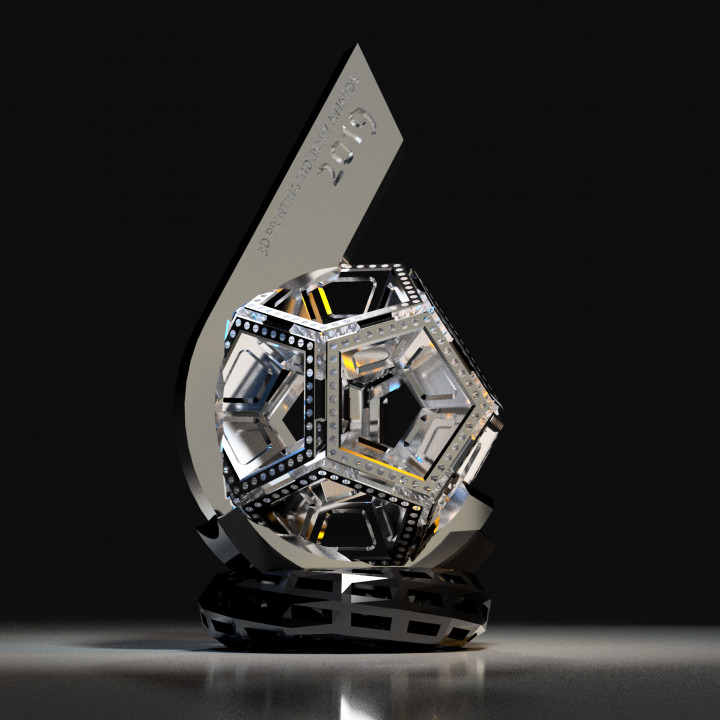

Clockspring’s Flame of Possibility design consists of a core of tapered pentagonal forms drawn through with internal features which are arrayed into a dodecahedron and fused together. A sleek slab curves from below and sweeps above, bearing the awards inscription, and providing space for any additional content. Underneath sits a faceted, wireframe Mobius-style torus, cradling the trophy body.

The trophy body is intended for SLA manufacture, and includes internal features to be revealed in translucent materials, whereas the trophy base is intended for MJF fabrication.

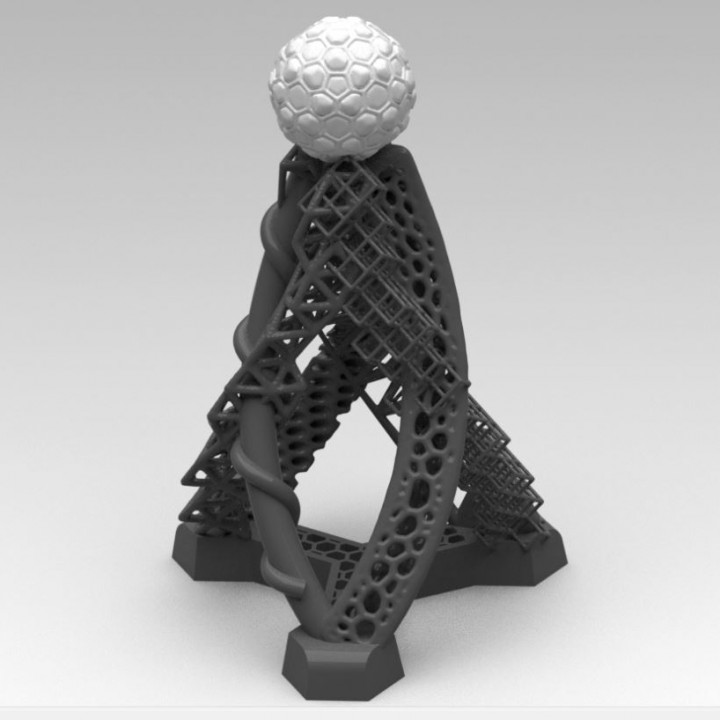

Colin’s Pillar trophy features 6 pillars of various styles which hold up a textured sphere that contains a double helix channel running through the centre. The complex base geometry with an intertwined assortment of lattices, internal helical channels and perforations demonstrates the design flexibility afforded by 3D printing.

The top textured sphere has tight internal corners that would be challenging to achieve via conventional means. An internal channel of a lattered double helix runs through the centre of sphere and is made visible by printing the sphere in a clear material.

The trophy is intended to be manufactured using MJF (Black, Grey, or other) for the base & pillars and SLA (clear) for the textured sphere.

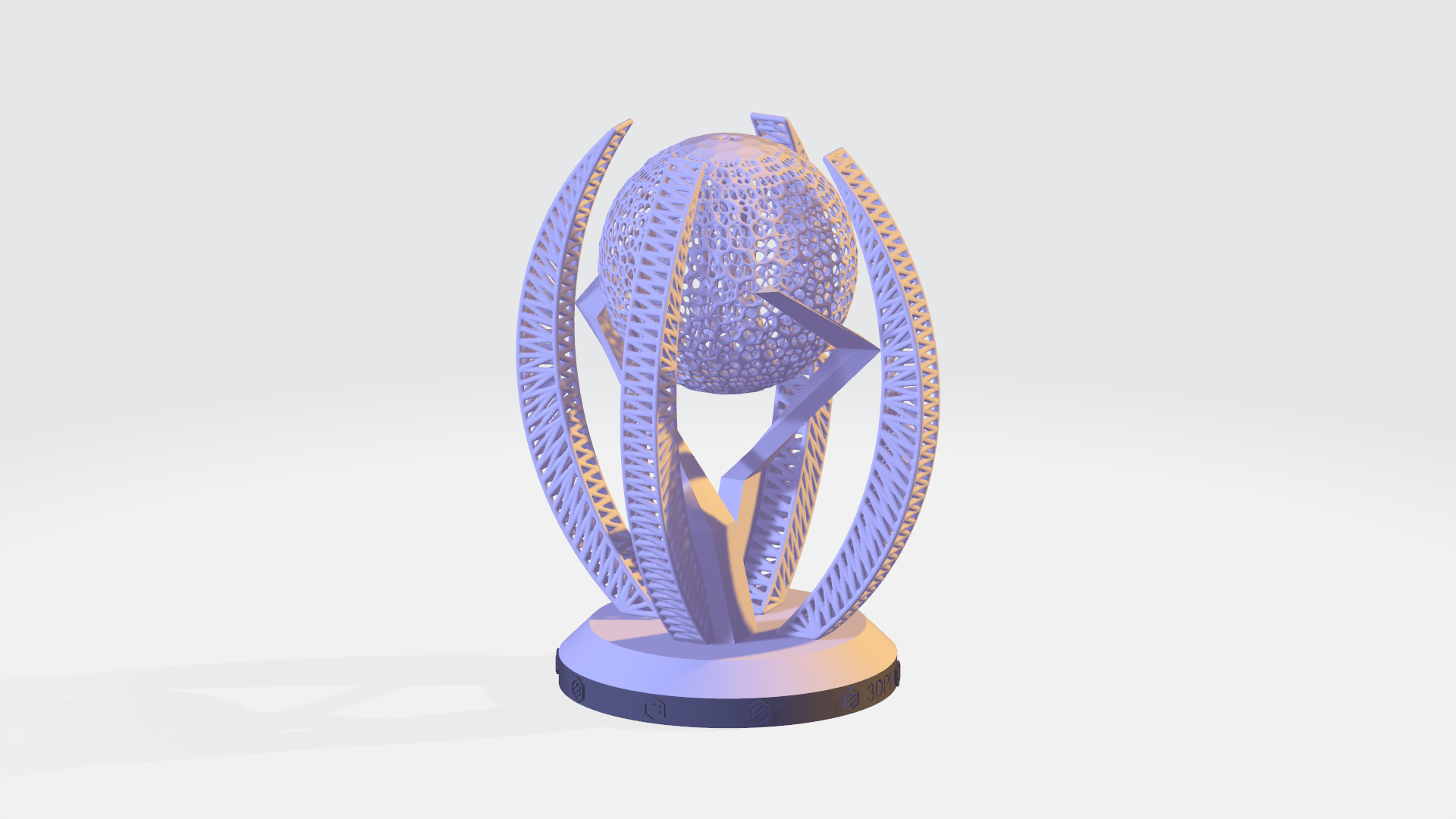

Lucas’s design aims to show the capabilities of today’s 3D printing. Features include a veronai pattern ball that will rotate inside the trophy body itself freely, creating an interesting feature only 3D printing can achieve.

Inside the ball Lucas includes even more complex geometry attempting to incorporate a vortex wormhole, symbolizing the speed at which 3D printing and manufacturing is accelerating.

In regards to it’s manufacture the the upper part can be printed in SLA, while the lower body will be printed in MJF giving the base a nice matte metal composite look with the Protolabs logo encapsulating it. The light bouncing from the matte grey MJF should bounce through the upper trophy part that will be printed in SLA as one piece.

The two bodies can be merged with a very thin paste of transparent epoxy glue.

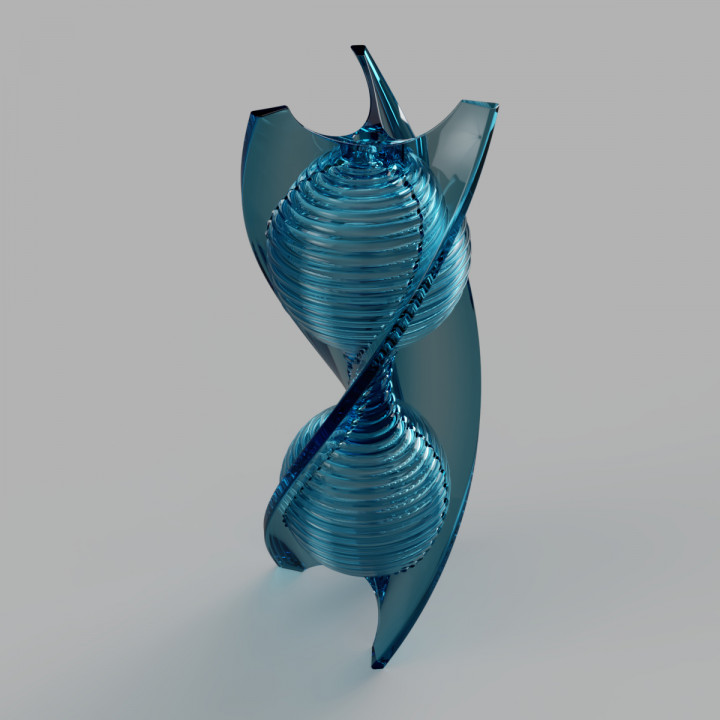

Albert Karlen’s Hourglass design is a twisting blue obelisk.

This inception style design by Jim Brown includes 3 3D printers inside of one another. This references self-replicating recursive 3D printing replication.

Chris Bobo’s trophy was designed using both Fusion 360 and Meshmixer and printed on an Anycubic photon.

Design brief recap

The task is to design a trophy that truly embodies the possibilities of 3D printing, and Protolabs’ state of the art manufacturing capabilities. The winner will have access to the full capabilities of Protolabs, state of the art, additive manufacturing machinery.

With this in mind, you should design a trophy that will celebrate the unique capabilities of 3D printing, whilst pushing Protolabs manufacturing capabilities to the limit.

You will also receive your design made using Protolabs advanced manufacturing technology.

Trophy design guidelines

Your submission to the 2019 design competition should:

– Be designed to be made in two different materials, one part SLA and one part MJF

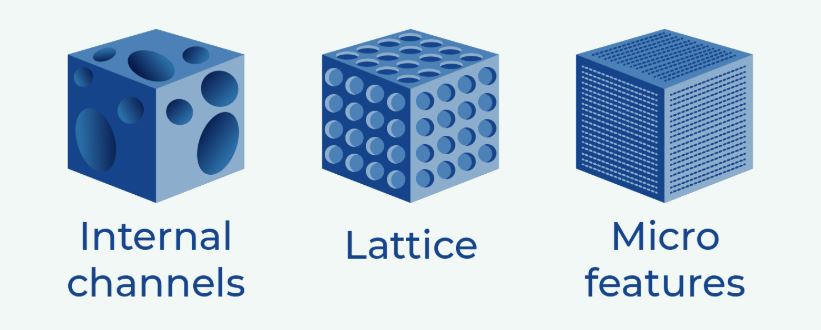

– Use internal channels

– Incorporate multiple features that are minimum 0.15-0.20mm in size (preferably in the same orientation) for SLA parts

– Have a minimum feature size for MJF parts of 0.75 mm

– Have a min/max trophy size of: 75x75x75mm/125x125x125mm

– Be optimised for SLA and HP’s MJF

Last year’s winner, Sruthi Venkatesh attended the Awards dinner and was a first time MMF designer, so the competition is really open to anyone.

Some final tips

– Think about your design(s) in relation to the brief and how best you might best optimise it for 3D printing.

– Make sure you read all the design constraints and download all designer resources so as to ensure you are on the right track.

– This year, the company is also looking for unique designs that incorporate both SLA and MJF 3D printing techniques

– Once your design is approved, post it on twitter with the tags #3DPIAwards, @MyMiniFactory, @3DPrintIndustry, @Protolabs

The 3D Printing Industry Awards will take place on June 6th 2019 in London.

Please also remember to vote in the 2019 3D Printing Industry Awards. For more information on the latest trends in additive manufacturing subscribe to our 3D printing newsletter and follow us Facebook and Twitter.

We also have jobs in the industry, visit our 3D Printing Jobs board to find out more.