The World Economic Forum (WEF) and McKinsey & Company, a New York-based management consulting firm, are conducting a global search and assessment for “Fourth Industrial Revolution [4IR] production lighthouses”— facilities actively deploying 4IR technologies within manufacturing.

“The majority of [4IR] tools have been implemented at scale in select factories, and we are on a mission to find them, learn from them and improve the adoption and diffusion of 4IR technologies,” stated Helena Leurent, Head of Future of Production, Member of the Executive Committee, WEF.

Overcoming pilot purgatory

According to McKinsey & Company, 4IR, the digitization of manufacturing process, is expected to create up to $3.7 trillion in value to global manufacturing. With additive manufacturing, cyber-physical systems, the Internet of Things (IoT), and cloud and cognitive computing, manufacturers can streamline series production costs as well as overall output.

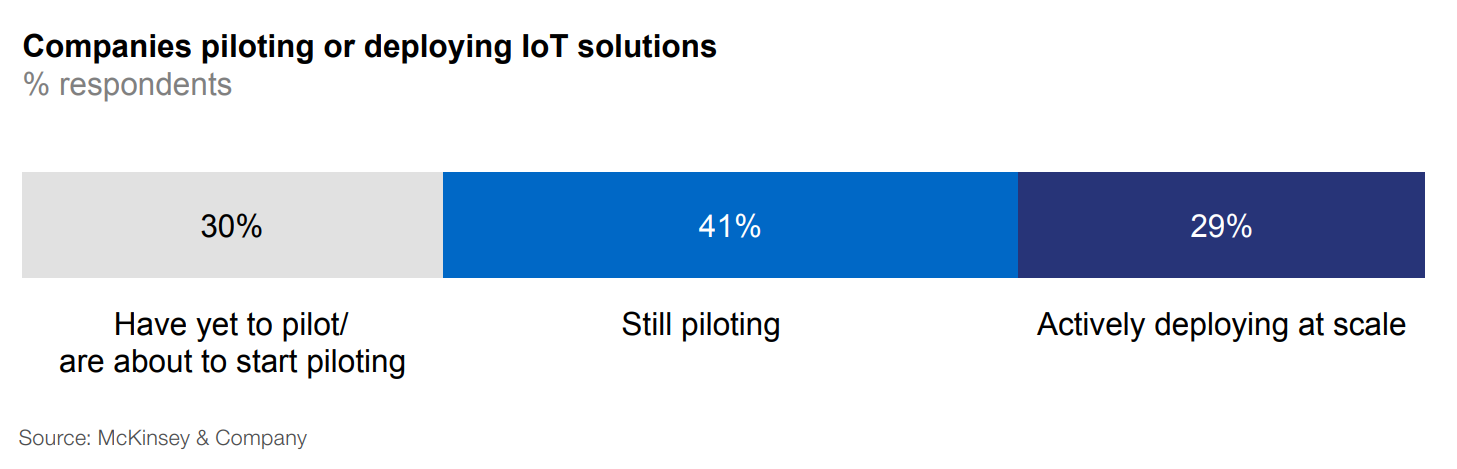

However, according to a recent McKinsey report, the adoption of such technologies remains somewhat stagnant due to pilot purgatory – where companies are trialing various digital manufacturing technologies but do not successfully roll them out at scale.

Thus, the long-term goal of this research is to create a global learning platform similar to the Toyota Production System (TPS), which will share selected 4IR lighthouse sites with the aim of informing the manufacturing community on the best practices for technology adoption of 4IR technologies.

The Lighthouse candidates

There are currently 30 undisclosed sites who have responded to this worldwide call to action. Within this amount, the current studies have revealed that the financial and operational impact achieved by at-scale deployment and the varying digital technologies integrated by the manufacturers are critical factors in the successful rollout of 4IR technologies.

WEF and McKinsey have highlighted three lighthouses where“4IR has truly been imbued into the ethos of the site” to overcome such hurdles. This included a French-headquartered global specialist in energy management, a Swiss-headquartered digital solutions company, and a US-based logistics company.

Nonetheless, one facility has been revealed as Johnson & Johnsons’ DePuy Synthes site in County Cork, Ireland. This lighthouse manufacturers 3D printed medical implants, such as the TRUMATCH Personalized Solutions Shoulder System. DePuy Synthes is using IoT technology to make old machines “talk to one another” which has resulted in a 10% reduction in operating costs, and a 5% drop in machine downtime.

The lighthouse candidates are also being studied to develop a library of best practices to be leveraged by the WEF members. Official recognition of the lighthouses is expected at the WEF Annual Meeting of New Champions held from 18-20 September in Tianjin, China.

The search for sites will continue through to the WEF 2019 annual meeting in Davos, Switzerland.

Catch more of the latest 3D printing news by subscribing to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the digitization of manufacturing processes. Image via Mckinsey & Company.