The United States Department of Veterans Affairs (VA) for military healthcare is applying 3D printing to the development of artificial lungs.

Though still a very early proof-of-concept project, Dr. Joseph Potkay, a biomedical engineer at the VA Ann Arbor Health Care System, Michigan, hopes that minute, 3D printed chips, could one day be used to used to provide therapeutic support for failing organs.

Freedom to breathe

Dr. Potkay and the Ann Arbor team’s long term goal is to develop possible treatments for people affected with chronic obstructive pulmonary disease (COPD). Caused by the inhalation of toxic substances, e.g. diesel exhausts, industrial chemicals and smoke, COPD is a common condition affecting middle-aged or older adults and, according to VA, over 16% of the U.S. veteran population;

“Over 500,000 service-connected respiratory disabilities have been diagnosed in veterans and 6.5% of all Gulf War service-connected disabilities are respiratory system related.”

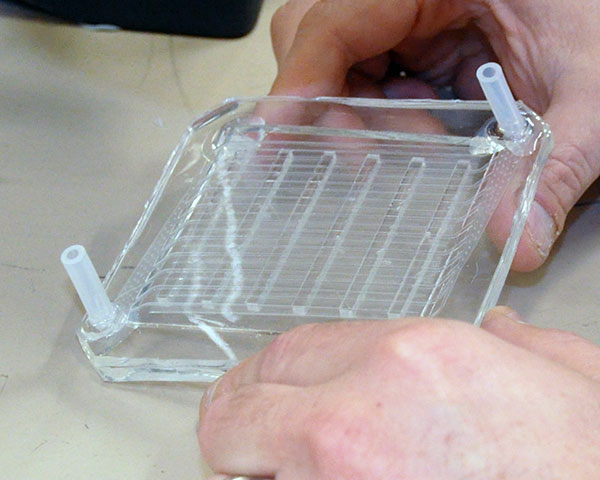

As a result of COPD, excess carbon dioxide is carried in the bloodstream. The Ann Arbor team’s first step towards its long term goal is to produce a device that can help regulate healthy CO2 content. Seven years ago, in 2011, the team advanced with the fabrication of a 2D plate containing microfluidic channels.

Through animal tests, this 2D plate has reportedly proven to achieve “the highest gas efficiency exchange of any artificial lung to date.”

In this next version, Dr. Potkay explains, “The flexibility in design afforded by 3D printing gives us more freedom and thus the ease to build artificial lungs with a small size and pressure drops that are compatible for operation with the body’s natural pressures.”

Can it last a lifetime?

Proving functionality is one thing however, and biocompatibilty will remain one of the greatest challenges to the artificial lung project. At present, the 2D device can last up to one week when implanted but, says Dr. Potkay, “We believe the 3D-printed device should be better than the 2D version but we don’t have proof yet.”

He adds, “Although the 3D artificial lung is more promising, it is earlier in development and still not guaranteed to work.” For now, the team plans to further preclinical testing of its 2D and a prototype 3D device with larger animal models.

Dr. Potkay concludes, “We’re further along in developing the 2D device, and we have plans to work around the challenges with that device.”

3D printed lungs

According to the World Health Organization COPD accounts for an estimated 6% of all deaths worldwide. As such, there are many projects around the globe searching for a solution. Most recently, additive manufacturing giant 3D Systems announced that it would be joining United Therapeutics Corporation in the development of 3D printed human lung treatments.

Wake Forest Institute for Regenerative Medicine‘s Body-on-a-Chip device is also linking microfluidic lung chips to the liver and the heart, working towards a more complete micro-model of the whole human body at work.

Keep up with the latest medical 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Seeking new professional opportunities? Search and post 3D Printing Jobs now.

Featured image shows biomedical engineer Dr. Joseph Potkay, with the VA Ann Arbor Health Care System, displays a 2D prototype of an artificial lung. A 3D version is in production. Photo by Brian Hayes/VA