Californian metal 3D printer manufacturer VELO3D has released the VELO3D Assure Quality Assurance and Control System for its laser powder bed fusion (LPBF) Sapphire 3D printers. On demand 3D printing service Stratasys Direct Manufacturing is the first to implement the system, validating its value in charting the part quality needed for volume production.

Benny Buller, founder and CEO of VELO3D, explained, “Assure is a revolutionary quality-control system, an inherent part of the VELO3D end-to-end manufacturing solution for serial production.”

“Assure is part of our vision to provide an integrated solution to produce parts by additive manufacturing with successful outcomes.”

VELO3D and metal 3D printing

This year, VELO3D has made several moves to accelerate metal additive manufacturing in sectors such as aerospace and automotive. In February, the company enhanced its Flow print preparation software to determine predictable print outcomes using an integrated simulation engine and reduce print preparation time. Prior to this, VELO3D partnered with Connecticut’s Praxair Surface Technologies, Inc. (PST), to develop and qualify process parameters for its materials.

More recently, it began collaborating with Boom Supersonic, a Colorado-based aerospace company, to 3D print flight hardware for the XB-1 aircraft, as well as Australian automotive company PWR, to create new cooling technology.

Within this time, Stratasys Direct Manufacturing also began working with VELO3D. Following its installation of a Sapphire 3D printer, the Stratasys subsidiary started testing VELO3D Assure software.

VELO3D Assure

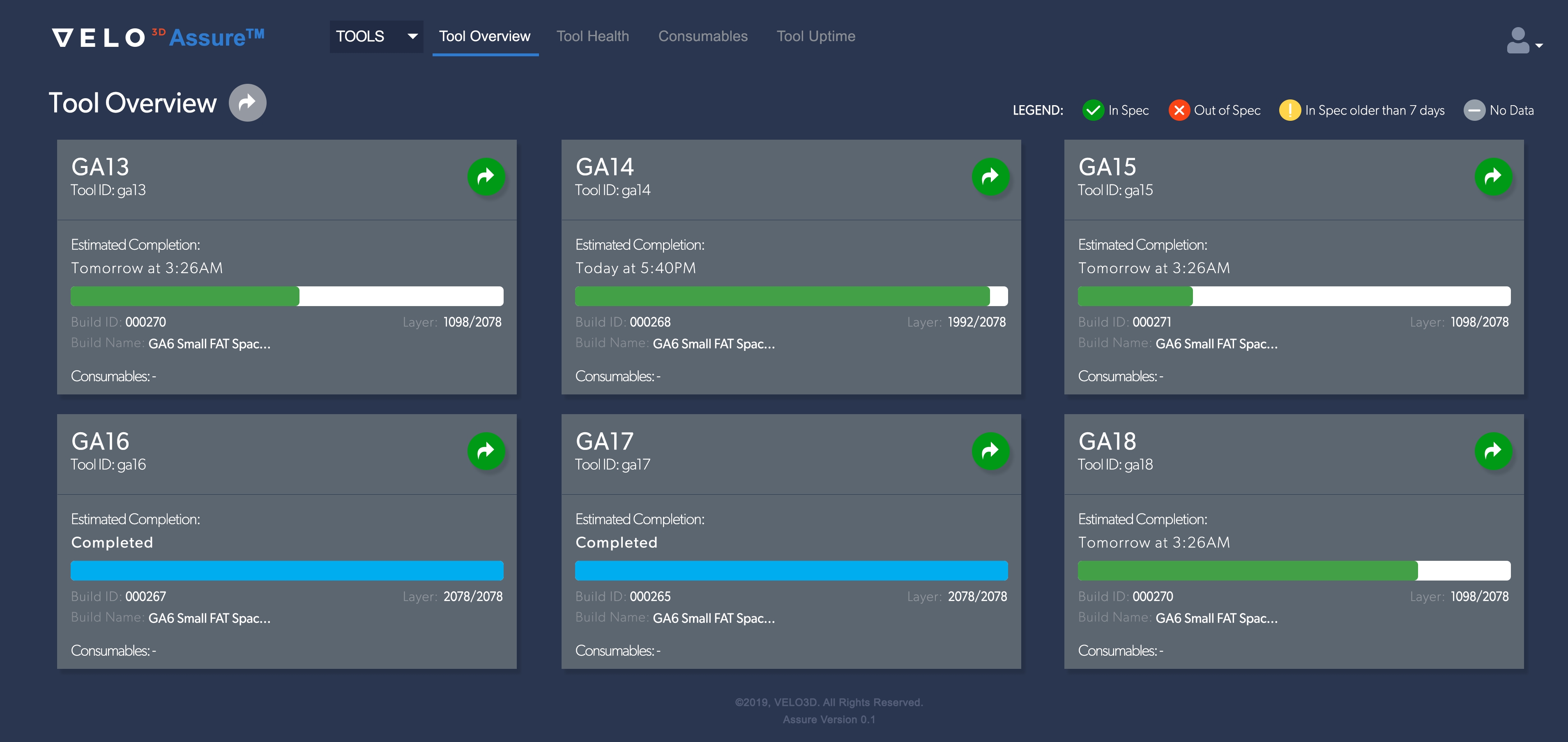

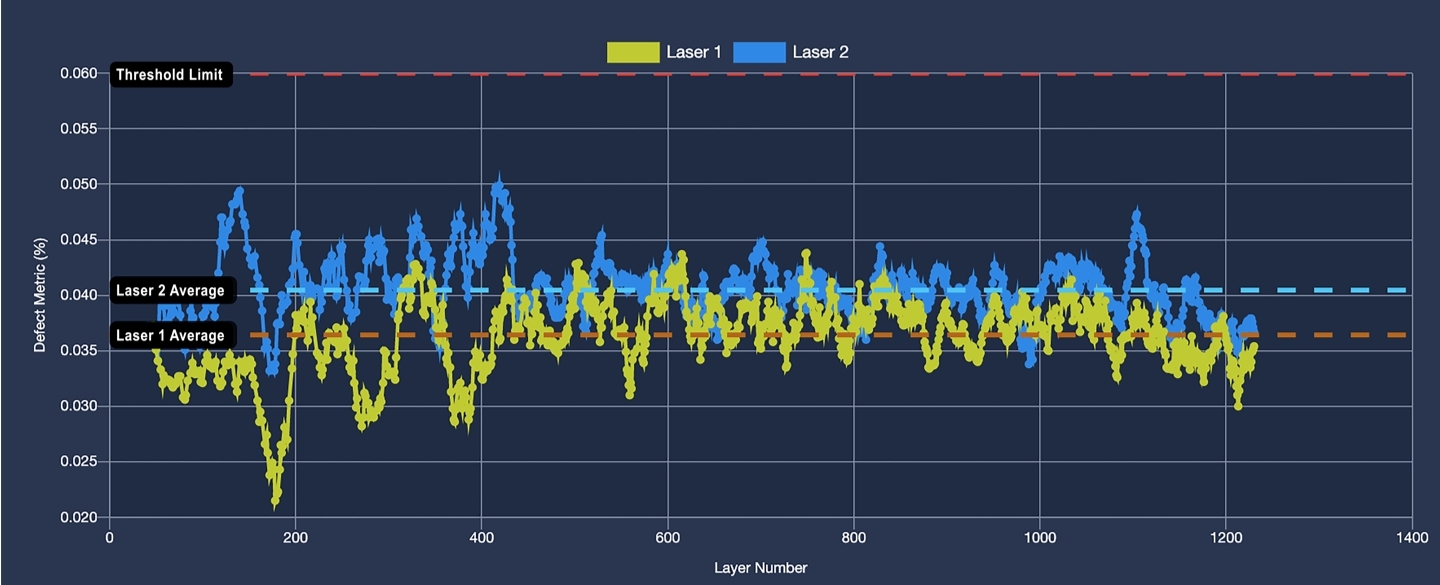

VELO3D Assure is capable of detecting process anomalies, flagging them and highlighting necessary corrective actions. Using real-time, multi-sensor, physics-based detection algorithms, the software can also trace part quality, decreasing variations for comprehensive documentation, thus streamlining 3D printed-part validation.

Stratasys Direct Manufacturing implemented Assure with these functions for the production of parts on several builds and assessed them in a recent whitepaper. Kent Firestone, CEO of Stratasys Direct Manufacturing, added, “Stratasys Direct has built a culture of continuous improvement that means we are continually setting new standards for our industry on quality.”

“We integrated Assure into our quality control workflow because it produces highly actionable insights. The user interface features intuitive graphs and charts that enable us to see and interpret the vast amount of data collected during builds.”

“This information helps our engineers verify the quality of the build each step of the way, and enables them to make quick decisions in the event of an issue. Assure helps us reduce production variation, improve yields, and circumvent anomalies to ensure consistent additive manufacturing.”

Stratasys Direct Manufacturing will host a webinar on November 14th at 10 am PST on VELO3D Assure. Those interested can register here. Both VELO3D (Hall 11, E79) and Stratasys (Hall 12.1, D61) will also be present at Formnext in Frankfurt, Germany, next week.

Subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter for all the latest 3D printing news comiing from Formnext and beyond. Visit 3D Printing Jobs for new opportunities in additive manufacturing.

Featured image shows VELO3D’s Assure predicting defectivity as a function of layer number. Image via VELO3D.