Today’s Q&A with a Formnext 2019 start-up challenge winner is with Matthias Kaiser, the CEO of Exponential Technologies Ltd.

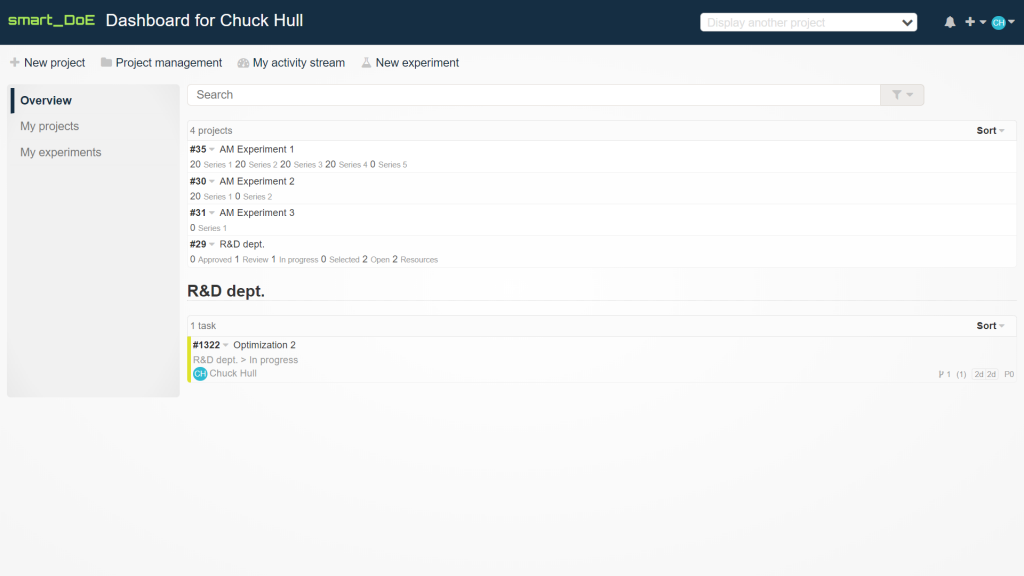

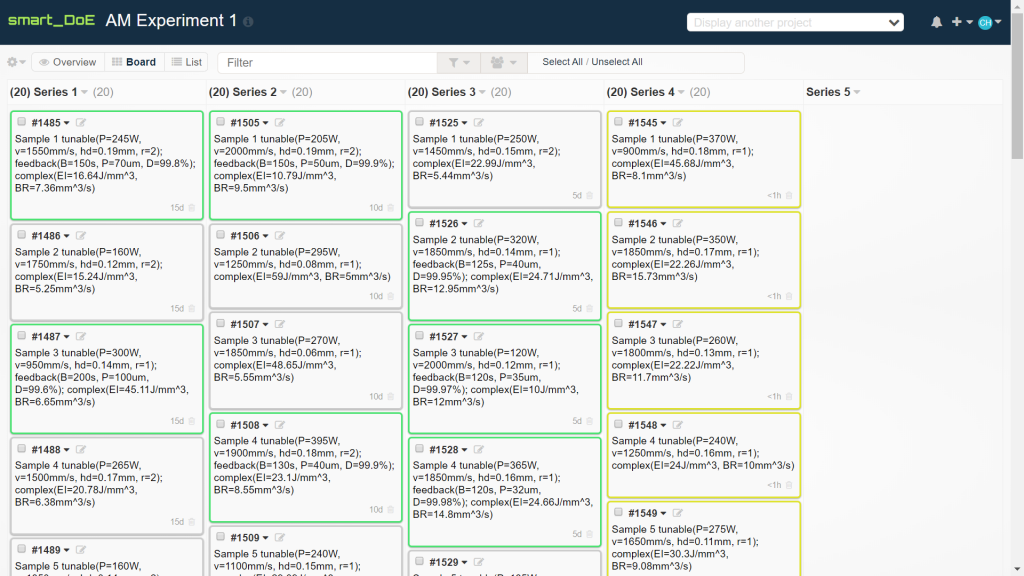

Exponential Technology provides a Research Management System (RMS) and an AI-driven Design of Experiment (DoE) software. The start-up aims to address challenges in additive manufacturing, including hastening the pace of material innovation.

3D Printing Industry: When was your company founded and where are operations based?

Exponential Technologies: Our company was founded in July 2019, however, the technology was developed over the course of the last 3 years. We are based in Latvian, one of the three Baltic states. This is a huge benefit as Latvia has a very good ICT infrastructure and many motivated and well-educated programmers and engineers.

3D Printing Industry: What does your company do?

Exponential Technologies: We are a software company specialized in the application of artificial intelligence algorithms to challenges in industrial manufacturing. Currently, our main focus is to speed up the development of new materials in the field of additive manufacturing. This we achieve by using specially developed, small data AI algorithms to support R&D engineers in the development of new materials and in the development of machine configurations to print these materials. Our software does that typically 10x faster than any other solution on the market.

3D Printing Industry: How does your company fit into the additive manufacturing ecosystem?

Exponential Technologies: Finding new materials with specific properties for the use in additive manufacturing is one of the major challenges in the additive manufacturing market. Making these new materials and traditional materials printable is another very difficult task. So difficult in fact, that in additive manufacturing we have only around 100 materials available for manufacturing. In classical manufacturing, there are roughly 10,000. To assure future growth of the AM market, thousands of new materials have to be developed and made printable over the next years. We can add significant value here, as we allow our customers to reduce R&D costs and go-to-market times of new materials drastically. In the long run, the whole AM ecosystem will benefit from this.

3D Printing Industry: What are you hoping to gain from exhibiting at Formnext 2019?

Exponential Technologies: We will launch our two new products, xT smart_DoE and xT edge at formnext 2019, so we hope to meet many new customers there. We are also very much looking forward to many interesting meetings with potential partners to discuss how we can help to transform the AM market even further. Very important for us is also to meet our existing customers to get feedback to our product and discuss how we can improve our software.

3D Printing Industry: How would you describe the roadmap for your enterprise in the coming years?

Exponential Technologies: We have big plans for the next 2-3 years. At the current moment, I can’t give too many details, but we have planned some jaw dropping features for the next versions of our software. One future feature will be machine-to-machine translation of printer configurations between printers of different manufacturers. We are also working on material composition and printer configuration prediction. However, we are still searching for the right partners to move these innovations ahead.

3D Printing Industry: Is there anything else you would like our readers to know about?

Exponential Technologies: We are looking forward to meeting you at our booth 12.0-B81J and discuss how we can help you to overcome your most pressing challenges using our knowledge and experience in artificial intelligence and engineering.

More information about Exponential Technologies is available online.

The 3D Printing Industry team will be back in Frankfurt for formnext next week. Get in touch if you’d like to meet. If you can’t attend the show, then follow our social media accounts on Twitter, Facebook, and LinkedIn.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

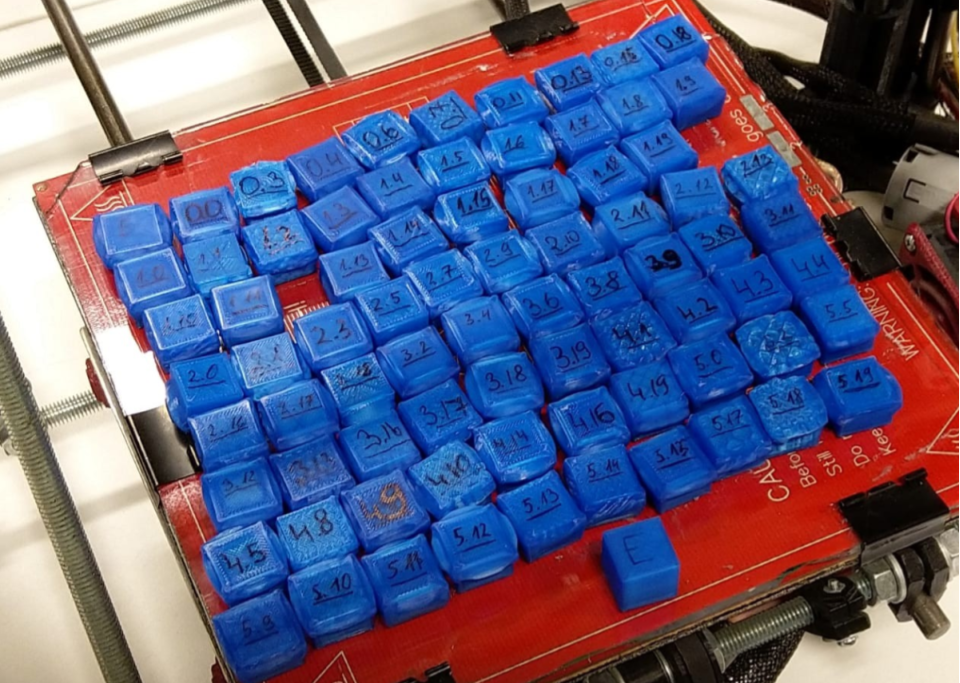

Featured image shows Optimization of SLM printing process, using a copper alloy, to maximize density and minimizing pore size and keeping print time at an acceptable level. Photo via Exponential Technologies Ltd.