A Pancreatic Islet Cell Transplantation (PICT) 3D bio-printer has been developed by researchers from the University of Wollongong’s ARC Centre of Excellence for Electromaterials Science (ACES) and will be used to treat diabetes at the Royal Adelaide Hospital (RAH) in Australia.

The bio-printer, which is capable of producing pancreatic islets suitable for transplantation to diabetes sufferers via micro-valve ink jet dropping, was handed over to South Australian Minister for Health Peter Malinauskas by ACES Executive Director Prof. Gordon Wallace on 6 December.

It will now be developed further at RAH by Prof. Toby Coates and his team using the Australian Research Council’s Linkage, Infrastructure, Equipment and Facilities (LIEF) grant.

In August, Wallace revealed in 3D Printing Industry’s “The Future of 3D Printing” series that Coates’ team was capitalizing on 3D printed biomaterial scaffolds to facilitate islet cell transplantation.

The problem of type 1 diabetes

Type 1 diabetes is a condition resulting from the body’s inability to produce insulin, a hormone that is necessary to control the amount of glucose in the blood.

Insulin is normally produced in the pancreatic islets (or islets of Langerhans), a tissue region of the pancreas. Type 1 diabetes destroys the insulin-producing cells in the islets.

One way of treating type 1 diabetes is via the transplantation of islet cells from human donors, which restores the diabetes sufferer’s ability to produce insulin and regulate their blood sugar levels.

However, currently only the most severe cases of type 1 diabetes can be treated this way since it is an expensive and inefficient process dependent on the availability of pancreases for transplantation.

Coates announced in April this year that his team was looking for a solution in the form of 3D bio-printing.

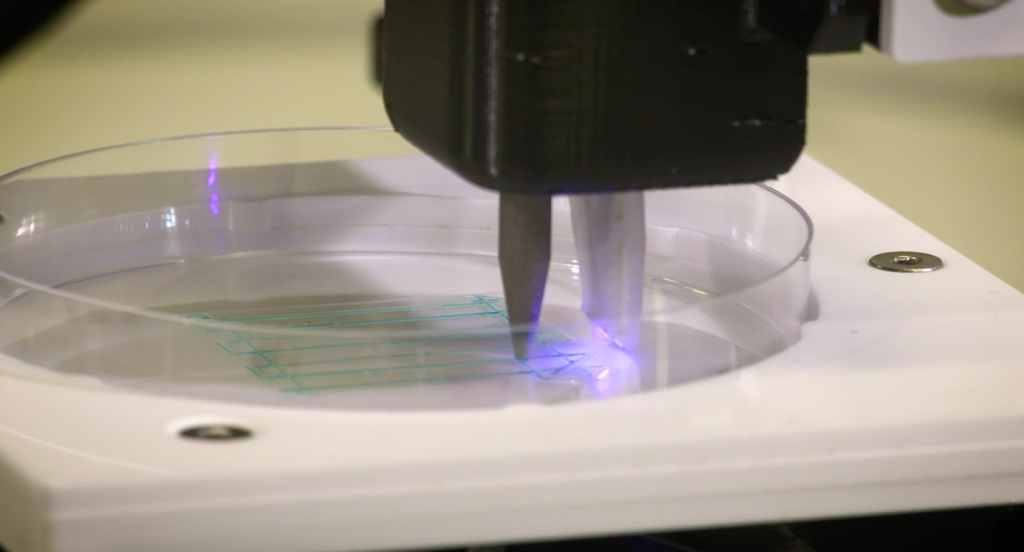

Micro-valve ink jet dropping to print scaffolds and cells

UOW’s Dr Stephen Beirne explained that using 3D printing would resolve this problem in two ways. It would firstly provide the “ability to precisely locate the cell that you want in an environment that you wish to make it” and secondly enable one to “modify that environment in the inks that you used to actually print it.”

In order to “build a structure that will retain the islet cells in place” and “discretely position other cells or growth factors within the scaffold structure itself,” a 3D bioprinting process called micro-valve ink jet dropping is required. This process allows the simultaneous deposition of multiple biological materials.

A bioprinting breakthrough

Consequently, the PICT 3D printer has enabled the development of “customized organs,” which combine “donor with recipient cells in a unique 3 Dimensional way to provide completely new composite “organoids” for experimental transplantation,” according to Coates.

The combination of donor and recipient cells is especially important as it reduces the likelihood of organ rejection. Endothelial cells can also be printed simultaneously, which ensures blood flow to the grafted islet cells.

‘’ACES at the University of Wollongong has built a collaborative clinical research network that enables us to tackle big clinical challenges and deliver practical solutions using 3D bioprinting,’’ Prof Wallace explained to the ACES news site.

“In collaboration with Professor Toby Coates’ team at Royal Adelaide Hospital, we plan to improve the effectiveness of islet cell transplants by encapsulating donated islet cells in a 3D printed structure, to protect them during and after transplantation,” he added.

UOW is currently building a dedicated 3D bio-printing facility following an AU$347,000 grant from the Australian Research Council. According to Wallace, the new bio-printing facility will be “a portal to global research and development activities in this area, as well as immediate commercialisation.”

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more information on world-changing 3D bioprinting breakthroughs, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

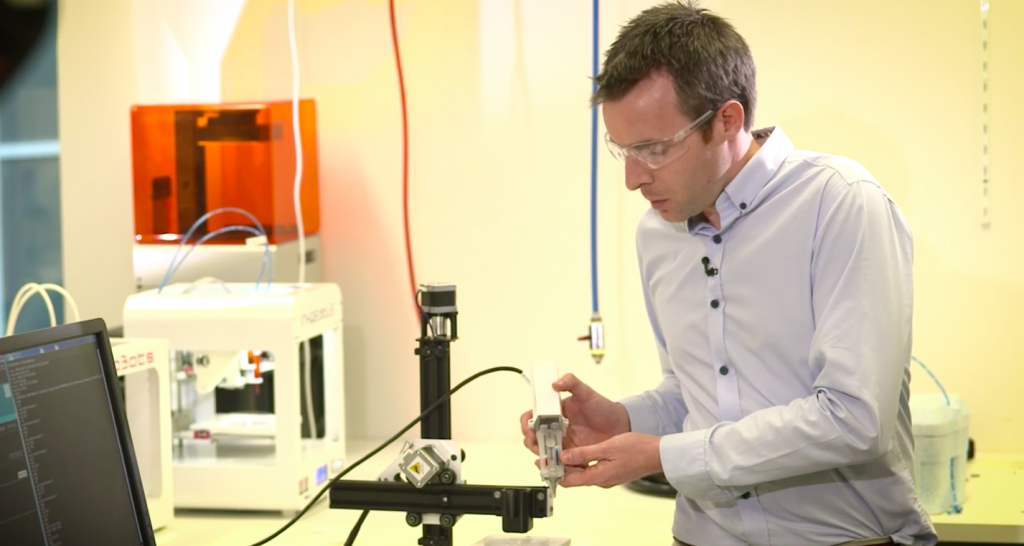

Featured image shows Gordon Wallace at the RAH launch of the PICT. Photo via ACES.