Two universities are establishing new 3D printing facilities with the help of funding from significant public grants. In Australia, the University of Wollongong (UOW) in New South Wales is to establish a 3D bio-printing facility following a AU$347,000 grant from the Australian Research Council.

In the USA, the University of Maryland, College Park, has opened a 17,000 square metre engineering centre, incorporating bioengineering and 3D printing innovation facilities. The centre named A. James Clark hall, has been funded State of Maryland and a number of private donors.

Bioprinting at Univeristy of Wollongong

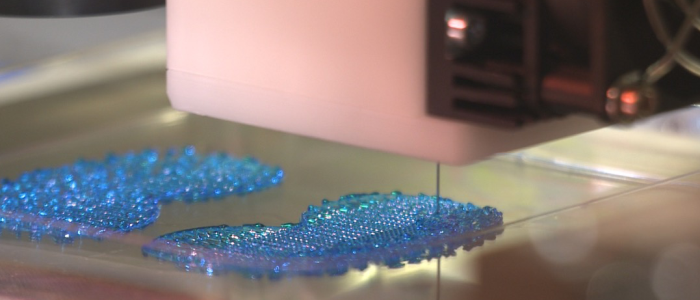

An AU$347,000 LIEF grant from the Australian research council has brought bio-printing one step closer to the University of Wollongong. The upcoming bio-printing facility will enable the development of bioinks and bioprinters for targeted clinical applications, and provide support to local bio-engineering enterprises like Venus Shell Systems, the iFixPen and the biopen.

The LIEF grant was awarded to the team of Prof. Gordon Wallace, director of the university’s Intelligent Polymer Research Institute. The 2017 New South Wales scientist of the year has led the bio-printing project together with the ARC Centre of Excellence for Electromaterials Science (ACES), and Australian National Fabrication Facility (ANFF).

Wallace stated that the new centre was“building upon earlier and current research activities in 3D bio-printing at UOW” and would provide “a portal to global research and development activities in this area, as well as immediate commercialisation.” Significant funding for the project has already been received from MTPConnect, the Medical Technologies and Pharmaceuticals Industry Growth Centre.

Wallace added that the the project would “address the current and future need for delivering 3D printing globally for research, applied science, medical devices and diagnostics and advanced therapeutics” and “enable production of relevant biomaterials, formulations of bio-inks and customised bio-printing systems.”

Bioengineering at Maryland

The University of Maryland’s new A. James Clark Hall is both a dedicated space for general engineering and bioengineering, and a hub for new regional partnerships and collaborations. University president Wallace D. Loh described it as a place where “great ideas will turn into life-changing devices and biomedical treatments.”

One way of achieving such a transformation is through 3D printing, which the university has already used in applications such as artificial retinas and FormaSTEM vascular grafts for congenital heart disease.

In the A. James Clark Hall, optical laser and imaging laboratories will house 3D printers for research, while cross-disciplinary research between medics and engineers will be facilitated through a series of flexible classrooms and labs.

Additionally, the university’s student newspaper reported that a new Center for Engineering Complex Tissues, funded by the US National Institutes of Health will be located at the facility. The new center will be dedicated to researching 3D printing in the fields of regenerative medicine and reengineered tissue.

The disclosed list of donors includes the State of Maryland, alumnus and bio-engineer Robert E. Fischell, T.K. Patrick and Marguerite Sung, Lawrence C. and Melanie Franco Nussdorf, Ronald and Karen Lowman, Rajan and Sandhya Mittu, and Pepco Holdings.

For more information on upcoming bio-engineering and bio-printing facilities, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows exterior of A. James Clark Hall, University of Maryland, College Park. Photo via UMD.