Scientists at the University of Minnesota have produced a 3D printed transparent skull implant them to observe the inner workings of mouse-brains in real time. Named the See-Shell it could provide new insights for human brain conditions such as Alzheimer’s and Parkinson’s disease.

The study published in the journal Nature Communications states that non-human primates, in this case mice, share similar genetics, anatomy, physiology, and behaviour with humans and so provide a good substitute.

Timothy J. Ebner, University of Minnesota Professor and a co-author of the study commented, “These are studies we couldn’t do in humans, but they are extremely important in our understanding of how the brain works so we can improve treatments for people who experience brain injuries or diseases.”

A window into the brain

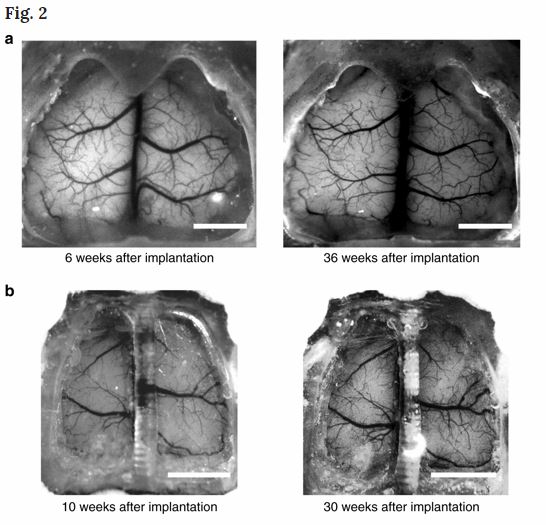

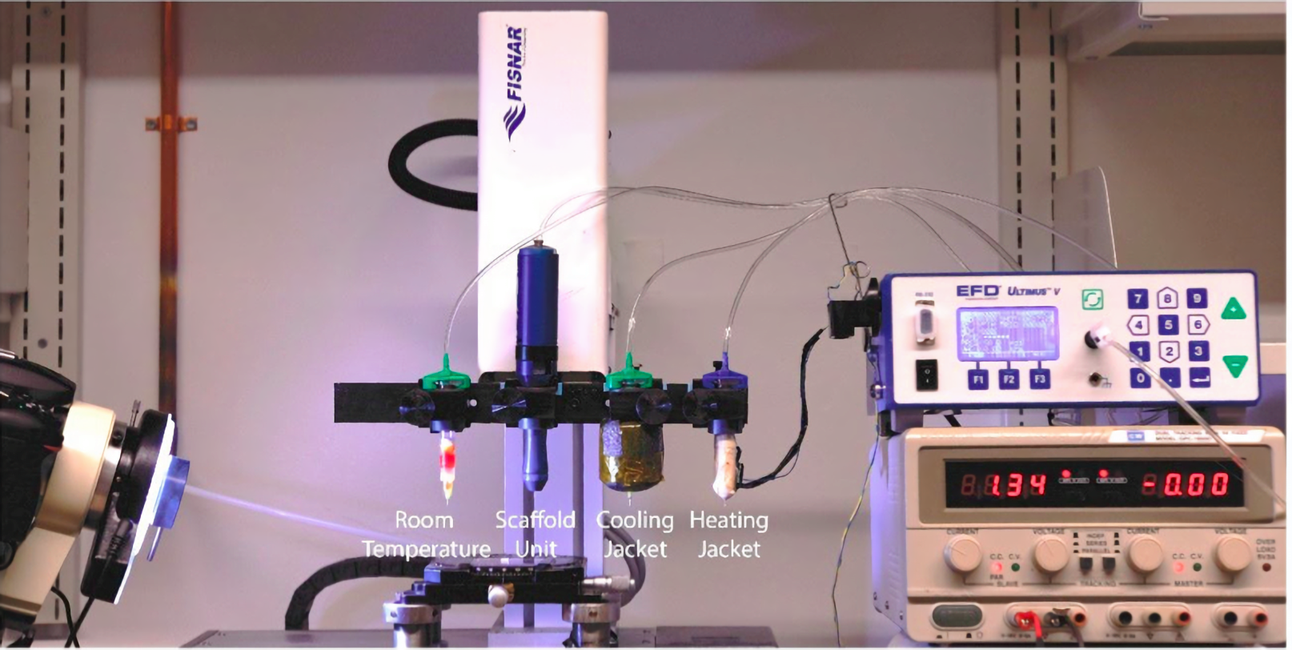

To make the See-Shell, researchers digitally scanned the surface of the mouse’s skull and imported this data into CAD software (Solidworks, Dassault Systèmes) to make a frame. This frame was then 3D printed out of polymethylmethacrylate (PMMA), commonly known as acrylic.

On to this surface a thin flexible and transparent polyethylene terephthalate (PET) film was attached, forming the window. The frame also included screw holes for fastening a custom-designed titanium head-plate which held the mouse’s head still during experiments.

PET was chosen for the transparent component as it has excellent optical properties and is biocompatible, meaning the body of the mouse is unlikely to reject the implant.

To attach the See-Shell they used a custom computer program to control the robot arm which removed a section of the mouse’s skull (craniotomy). The combined 3D printed frame and PET assembly was then attached to the skull.

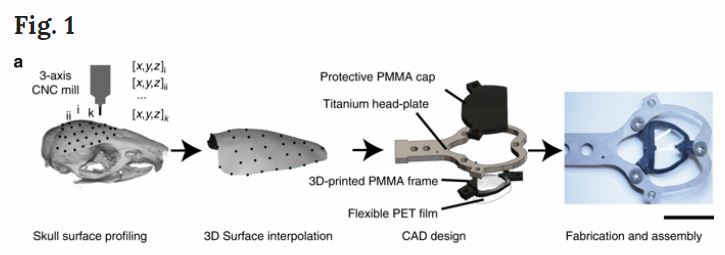

“This new device allows us to look at the brain activity at the smallest level zooming in on specific neurons while getting a big picture view of a large part of the brain surface over time,” said Suhasa Kodandaramaiah, Ph.D. a co-author of the study.

“Developing the device and showing that it works is just the beginning of what we will be able to do to advance brain research.”

A 3D printed translucent skull for everyone?

The paper also claims that several aspects of the design and fabrication of the See-Shell can be widely adopted, and co opted, in labs to further our understanding of the brain. The paper states that “See-Shells can be fabricated using desktop tools and are inexpensive (<$20 each). Once the individual components are fabricated (or procured from commercial fabrication services), the implant can be assembled in <15 min. Therefore, this is a tool that can be readily adopted by most laboratories.”

The technology is not limited to skulls either. The authors claim that See-Shells could also be engineered for use on complex and movable parts of the body, such as spines. “The 3D-printed frame can be modified to incorporate mounting features to precisely attach miniaturized microscopes and wirelessly controlled devices for infusing pharmacological agents or performing optogenetic stimulations.”

This latest advance adds to the University of Minnesota’s growing portfolio of 3D printed anatomical expertise, which includes a 3D printed bionic eye prototype and a 3D printed implant that restores functions in spinal cords.

A full explanation of this procedure, titled “Cortex-wide neural interfacing via transparent polymer skulls“is published online in Nature Communications. It is co-authored by Leila Ghanbari, Russell E. Carter, Mathew L. Rynes, Judith Dominguez, Gang Chen, Anant Naik, Jia Hu, Md Abdul Kader Sagar, Lenora Haltom, Nahom Mossazghi, Madelyn M. Gray, Sarah L. West, Kevin W. Eliceiri, Timothy J. Ebner & Suhasa B. Kodandaramaiah.

Submit your trophy design and cast your vote for the 2019 3D Printing Industry Awards now.

For the latest additive manufacturing news, subscribe to our 3D printing newsletterand follow us Facebook and Twitter. Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a small experimental mouse. Image via Shutterstock.