The University of Akron, Ohio in collaboration with Airborne Maintenance & Engineering Services (AMES), is seeking approval from the Federal Aviation Administration for their additive manufacturing technology that could repair aircraft parts. AMES is an aircraft maintenance and repair company that is well versed with the requirements of the industry.

The collaborative project is exploring the use of ‘cold spray’ technology to repair metal parts and are now at the stage of applying for FAA approval. According to the university, this project has been running for two years, with funding from Ohio legislature. The overall goal for the group is to provide “faster, market competitive, and safer airplane repairs.”

Supersonic Particle Deposition

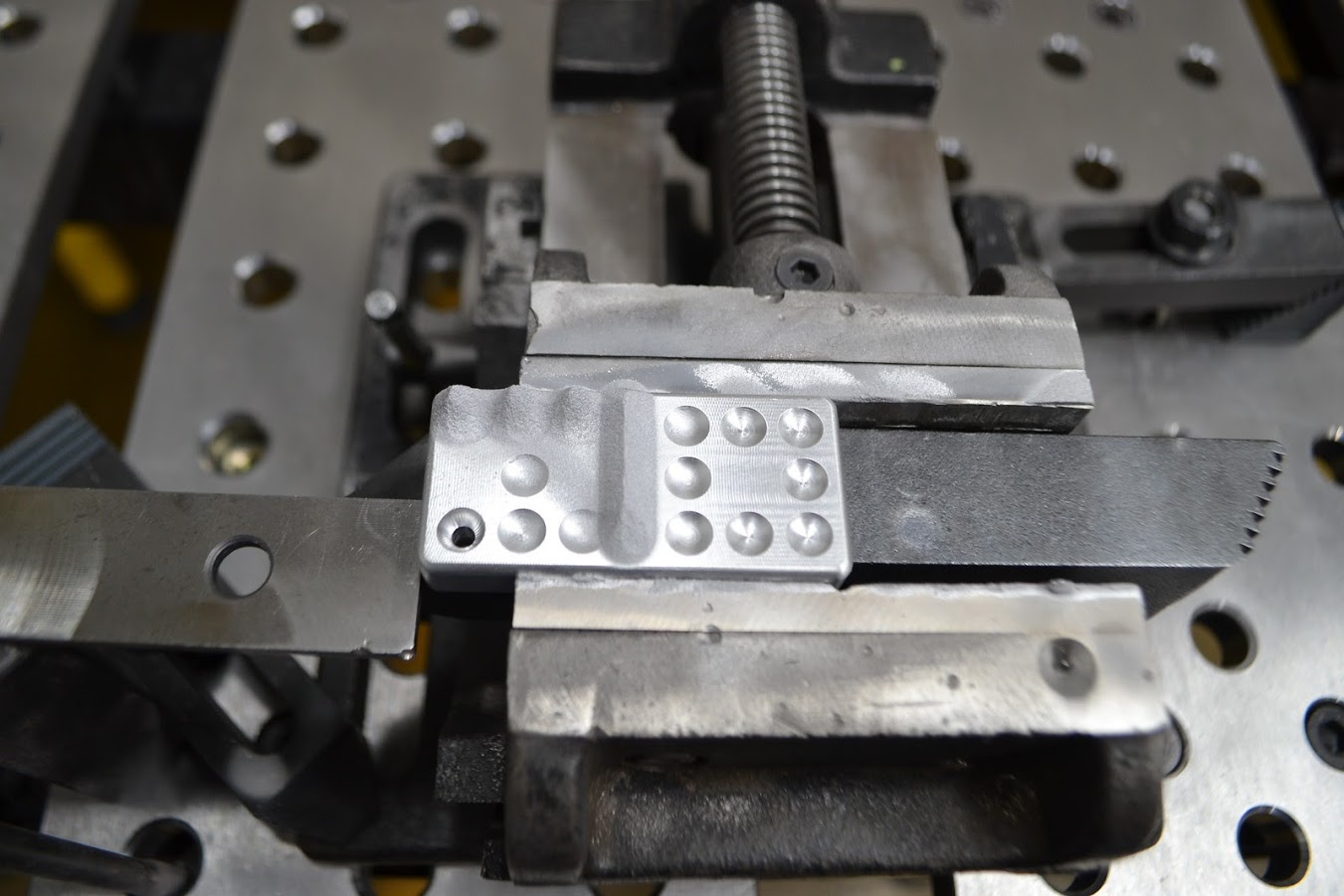

According to the university, the method – otherwise known as Supersonic Particle Deposition (SPD) – involves,

…a high pressure spraying process in which metal particles contained in a supersonic jet of an expanded gas impact a solid surface with sufficient energy to cause bonding with the surface.

The technology has application in the aviation industry as it, “repairs the surface of the metal part without creating a heat-affected zone that would occur during welding or high temperature thermal spray.” The idea is to repair corroded or worn parts by essentially spraying new layers of metal on to them, at supersonic speeds. SPD can direct the particles in to specific areas in order to allow for certain shapes. Cold spray technology has been explored by other projects in the past, such as the European Space Agency. However, it seems the University of Akron, together with AMES, may have made a breakthrough since they are at this approval stage.

National Center for Education and Research on Corrosion and Materials Performance

The University of Akron has a dedicated department that has led this project with AMES, the National Center for Education and Research on Corrosion and Materials Performance (NCERCAMP). The NCERCAMP was set up in 2010 by Congress and the U.S Department of Defense to address the cost of material corrosion on the economy which, they state, is estimated at $400 billion annually.

Rex Ramsier, University of Akron’s senior vice president and provost, spoke about the project,

This partnership brings together the University’s expertise in corrosion and materials science with the extensive experience that our partners have in aviation and technology to create an exciting opportunity for job creation and technological advancement in Ohio.

3D Printing Industry has reported on another advancement from the University recently, as they published research into a new Stereolithography method.

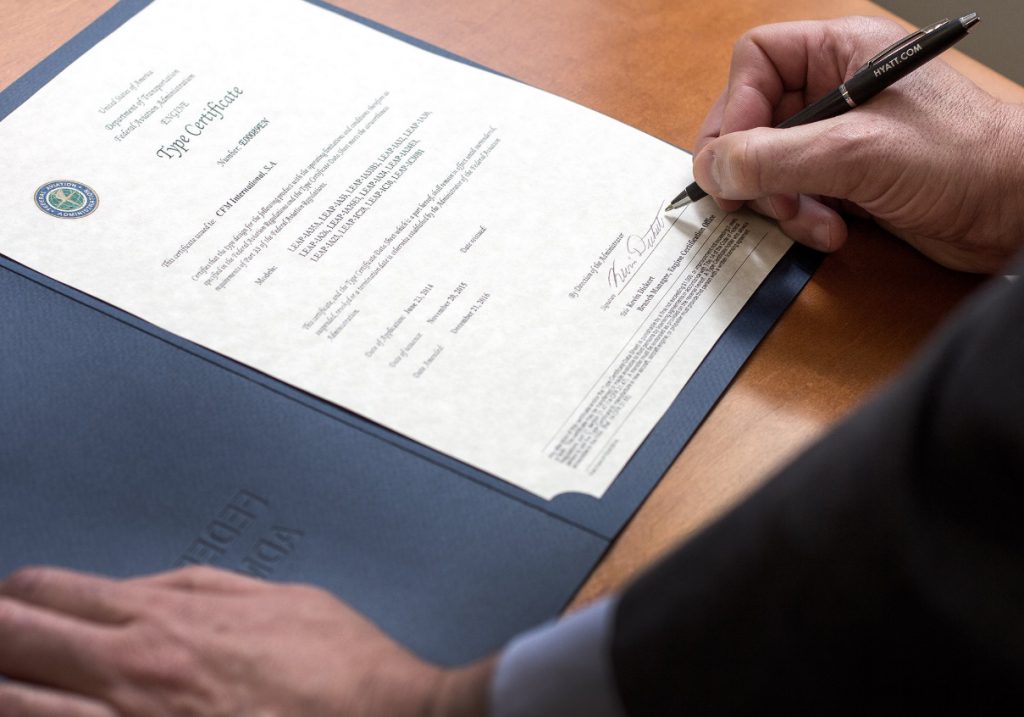

Federal Aviation Administration

Gaining FAA approval is essential to bring this process to market and doing so will simultaneously prove its validity in repairing the parts. GE has done just that recently with their, now famous, 3D printed fuel nozzle. GE, along with CFM, has gained certification for use of the LEAP nozzle.

Remember to cast your vote in the upcoming 3D Printing Industry Awards.

For the latest additive manufacturing news, sign up to our newsletter and follow us on twitter.

Featured image shows metal aircraft components.