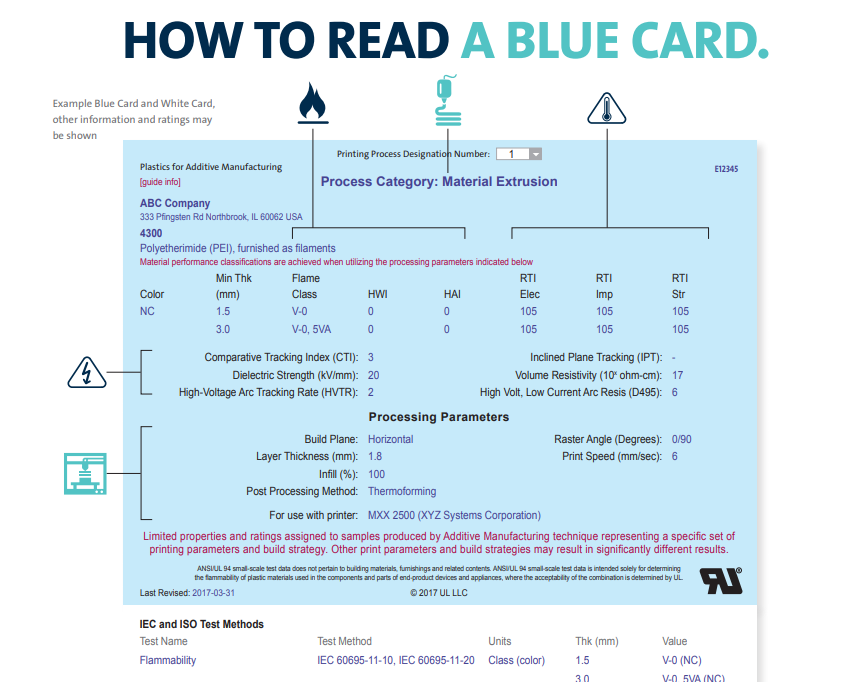

Underwriters Laboratories, or UL, the company responsible for thorough studies into the safety of desktop 3D printing and various other certification documents, has launched a Blue Card for additive manufacturing materials.

This card, also known as the Plastics for Additive Manufacturing Program, has been introduced by UL to help materials manufacturers reach their potential customers. Materials listed through the program are supported by independent testing and certification from UL, giving further product transparency and quality assurance.

According to the company, “The Plastics for Additive Manufacturing Program (Blue Card Program) is a UL service that enables customers to have published data that facilitates pre-selection of 3D printed materials and components for use in various end products,”

“It defines the requirements necessary to recognize plastics intended for 3D printing, proving the safety, integrity and usefulness of materials.”

Made for 3D printing

UL has over a century of experience in the development of industry standards and safety regulations. Headquartered in Northbrook, Illinois, the company works from offices in 46 countries around the world.

In traditional manufacturing, e.g. injection molding and vacuum forming, the UL Yellow Card for Plastics is a well established safety standard, particularly in the U.S. and Canada. The new Blue Card is an extension of this service, catering to the specific and varied requirements of 3D printing technologies.

Low-maintenance material marketing

Participation in the UL Blue Card program is linked to a product’s receipt of a UL Recognized Component Mark, a stamp of quality used to certify parts of a finished product before they reach the end stage.

Once a Recognized Component Mark is acquired, the material is given a Blue Card and automatically listed om UL iQTM and Prospector® databases, exposing it to the thousands of professionals and suppliers on the UL’s client list. In this way, the Blue Card works as a type of low-maintenance marketing for material manufacturers, which can be enhanced by the addition of a White Card highlighting the material’s best properties.

Saving time and money in certification

UL Blue Cards are available for polymers produced for seven 3D printing technologies, including: Material Extrusion, Powder Bed Fusion, VAT Polymerization, Material Jetting, Binder Jetting and Sheet Lamination.

For component and end-product manufacturers, the Blue Cards ensure that the materials they use have already been tried and tested saving time and money in the certification process after manufacturing. Follow-Up Services also ensure that the materials continue to meet UL standards of safety and performance.

To stay up to date with all the latest legal and regulatory challenges in the industry, subscribe to our newsletter, like us on Facebook and follow 3D Printing Industry on Twitter.

Get your voice heard in the 2019 3D Printing Industry Awards – nominations are open now. For career opportunities, search 3D Printing Jobs.

Featured image shows the UL Blue Card Plastics for Additive Manufacturing Program. Image via UL