Canadian plasma specialist PyroGenesis and French metal processing specialist Albert & Duval have agreed on terms to establish the production of powdered titanium 3D printer feedstock.

In a multi-step strategy outlined by the two parties at the beginning of January 2019, the companies have reached a mutually exclusive deal aiming to impact the additive manufacturing market in Europe.

P. Peter Pascali, President and CEO of PyroGenesis, asserts, “This Agreement establishes the framework within which Aubert & Duval and PyroGenesis shall work together to distribute the titanium powders manufactured by PyroGenesis to the Market. There are provisions for the expansion of the Market upon mutual agreement by the Parties,”

“This relationship will undoubtedly accelerate our growth in our AM business line and complements our corporate strategy to team up with established players who have an impeccable reputation and a strong balance sheet, to accelerate our growth.”

Finer powders for high quality 3D prints

PyroGenesis is one of only a handful of metal powder producers in the world to process materials using the plasma atomization process (PAP) – a method that the company originally patented in 1995.

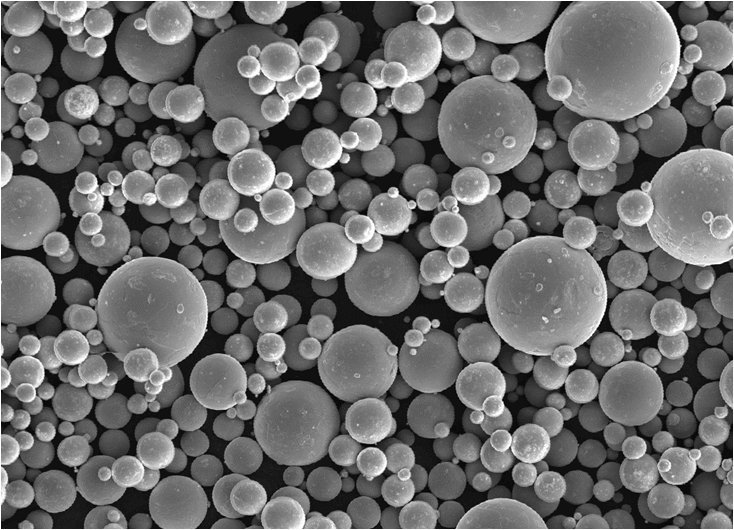

Applied to powder for additive manufacturing, PAP is capable of acutely controlling particle size distribution and making “small, uniform, fully dense and spherical metal powders that flow like water” – a quality which is transferred to the end products.

At present, PyroGenesis’ standard powder offering covers titanium pure CPTi, Ti 6Al-4V and grade 1, 5 and 23) and Inconel, though custom powders can be made on request.

Now in the midst of a round-the-clock production industrialization plan, the company recently opened a new metal powder facility focusing on its Ti-6Al-4V output. In December 2018, PyroGenesis also confirmed that a governmental body had placed an order for its products.

A 15% share of European titanium powder

Founded in 1902, Aubert & Duval is a subsidiary of French multinational mining and metallurgy company Eramet. Alongside Erasteel, Aubert & Duval constitutes the Eramet Group’s entire alloy range, with specialty in high-performance steel, super alloy, aluminum and titanium alloy production.

With PyroGenesis’ help, the Eramet Group is hoping to attain a 15% share in the European titanium powders market by 2020. According Jérôme Fabre, Eramet Group’s Deputy CEO in charge of alloys, “With our metallurgical expertise for demanding markets such as aeronautics and energy, this partnership with PyroGenesis allows us to complete our offer of metal powders for additive manufacturing, including 3D printing, a growing market of the industry of the future.”

PyroGenesis’ P. Peter Pascali concludes, “This is a very significant milestone not only for PyroGenesis and Aubert & Duval, but for the industry as a whole. This strategic partnership speaks to the Parties’ complementary strengths: PyroGenesis’ extensive plasma expertise as the inventor of Plasma Atomization, and Aubert & Duval’s large network of customers, strong balance sheet, and extensive knowledge of the market.”

Nominate your Materials Company of the Year and more in the 2019 3D Printing Industry Awards.

Subscribe to our free newsletter, follow us on Twitter and like us on Facebook for all the latest news updates. Find 3D printing jobs near you now.

Featured image shows firing on all plasma jets: Gas plasma jets as used in the atomization process. Photo via PyroGenesis.