AM UK, an independent, government-backed collaboration, has published a new Additive Manufacturing National Strategy. Over 44 pages a vision to bring together industry, academia, government and finance bodies and ensure the UK remains a leading high value manufacturing nation is set out.

With contributions from over 100 3D printing industry experts, the document provides substantial insights into the roadblocks around industrial digitisation and how to ensure opportunities in high value manufacturing are not squandered.

The strategy document notes that the UK, “has world-class additive manufacturing experience in research, design and manufacturing expertise.” However, “many UK companies, especially within the SME community, lack the awareness, resources or confidence to apply additive manufacturing as a core and integral part of their manufacturing toolkit.”

According to the authors of the UK Additive Manufacturing National Strategy document such deficits are likely to lead to an erosion of the country’s high value manufacturing (HVM) sector.

Dr. Paul Unwin, Chairman of AM UK, says, “This strategy is about communication; that AM is here to stay, well-proven and will make a huge difference.”

“As we head into Brexit, additive manufacturing can make a real change in the UK and we will be devising the training and education programmes needed to provide the additive manufacturing engineers of the future.”

High value manufacturing

In the UK, high value manufacturing is forecast to generate £3.5 billion per year by 2025. This gross value added (GVA) figure will support 60,000 jobs. By comparison, the report states that in 2015 high value manufacturing contributed a GVA of £235 million with under 5,000 jobs. The wider manufacturing industry in the UK employs 2.6 million people and earns £168 billion GVA.

The strategy presents a full set of recommendations, developed by work-groups responsible for particular themes. The focus areas are divided into three groups.

The technology group concentrates on the full and broad value chain of additive manufacturing – running from raw materials to final part qualification. The domain of skills and training includes apprenticeships, on-line training courses, reskilling programmes and further education. The final focus area is business support and supply chain development – examples of capital grants for investment in machinery and the development of a knowledge sharing platform are included here.

Within these groups, the barriers, market failures and burdens holding back the “full and rapid commercialisation” of additive manufacturing in the UK are identified. The strategy also identifies the public funding requirement – a figure of £225 million over the coming five years.

The vision is to, “drive the UK to the forefront of commercialised additive manufacturing”, this is supported by 10 specific aims:

- Address identified technology and market barriers that impede the rapid commercialisation, competitiveness and productivity of the whole additive manufacturing supply chain.

- Devise and deliver the training and education programmes needed to provide additive manufacturing engineers for today and the for the future.

- Help industry to exploit the competitive advantage to be gained by using additive manufacturing for prototypes, tooling and end-use parts.

- Develop additive manufacturing techniques, materials, inspection processes and standards to deliver outstanding results at industry-leading quality at scale.

- Provide the necessary infrastructure to help industry obtain commercial benefits from additive manufacturing.

- Create a ‘showcase’ for additive manufacturing to demonstrate how well it works in practice, supported by regional support as appropriate.

- Develop a strong network of additive experts in the UK and support knowledge transfer.

- Help industry access public funding and grants.

- Continue to undertake detailed market analysis to identify the opportunities, barriers and impacts.

- Attract funding, leveraging both private and public sources, to pursue opportunities enabled by research and innovation.

The UK Additive Manufacturing National Strategy makes 28 recommendations, these are grouped by working area.

Recommendations include

- Commissioning a study to classify additive manufacturing design guidelines.

- Funding R&D activity around creation of online tools to educate potential users

- Development of a material properties and standards database.

- Commission and publish case studies including data on the economics of additive manufacturing and related business models.

- Develop skills of current and future workforce.

- Support the development of an expert UK additive manufacturing User Group, similar to the successful U.S. model.

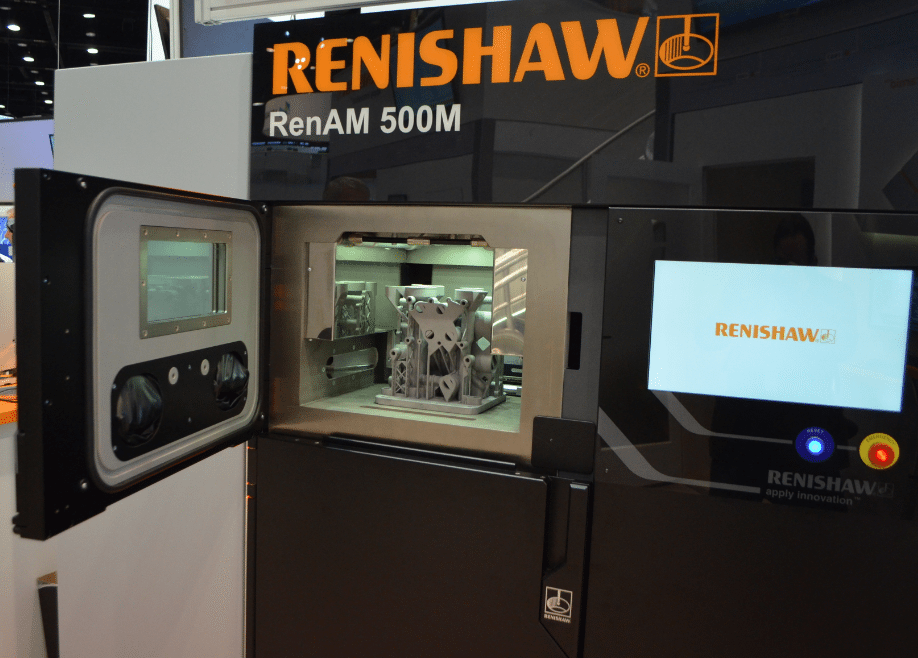

The report was prepared by the UK Additive Manufacturing Steering Group and supported by industrial leaders. Included in the acknowledgements are Philip Dell’Orco, (GlaxoSmithKline Research and Development), Rob Sharman (GKN Aerospace Services Ltd.), David S Holmes (BAE Systems), Sir David R McMurtry (Renishaw plc.), and Sir James Dyson.

Globally, a number of funded initiatives with additive manufacturing at their center are already up and running. The most well known of these is probably America Makes in the U.S.

Other initiatives include:

Australia – Advanced Manufacturing Fund

China – Made in China 2025

Germany – Fraunhofer Additive Manufacturing Alliance

India – Make in India

Russia – National Technology Initiative

Singapore – National Additive Manufacturing Cluster

South Africa – The Rapid Product Development Association

Dr. Unwin, adds, “Integrating AM into manufacturing is not easy, and a huge cost. AM has been the most exciting change-maker in medical technology, but we need more facilities around the UK to try out AM to realise its huge potential. The skills base is crucial. We need to equip our designers and engineers across the spectrum with the skills they require to take AM forward in order to catch up with the rest of the world and establish more UK businesses as major players in the global market.”

“There are currently a small number of well-trained, experienced AM experts who are leading the way. We need our students of today – and those of tomorrow – to grow up with the knowledge of this technology if we are to really make headway.”

The Additive Manufacturing UK National Strategy 2018-25 document is available to download here.

For all the latest news about additive manufacturing, follow our social media accounts and subscribe to our free newsletter.

Featured image shows the Additive Manufacturing UK National Strategy 2018-25 document. Photo by Michael Petch.