A team of researchers from UCLA has used 3D microprinting to produce what they are calling the early stages of a “lab-on-a-particle”.

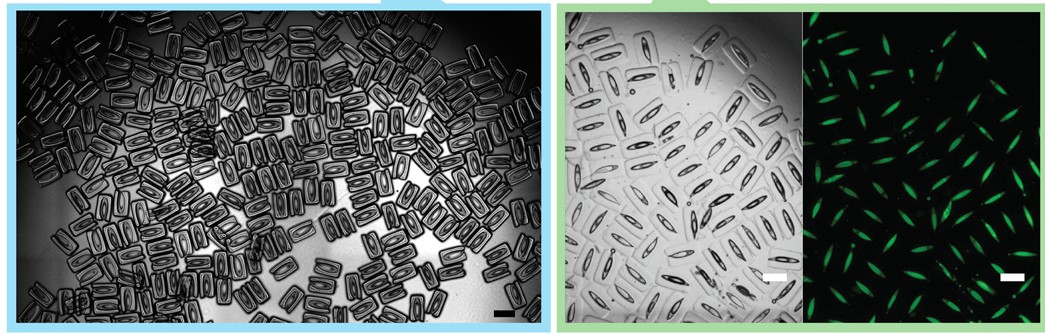

The printed structures resemble miniature U-shaped cups, or test tubes, and are only about half a millimeter in length. The UCLA researchers claim the cups can be used to facilitate parallel chemical reactions in a repeatable manner, as they can be reliably printed at the same size several times.

Dino Di Carlo, the lead author of the study, explains: “They’re like tiny test tubes, but thousands of times smaller than the ones currently used in laboratories. Unlike traditional test tubes, these ones automatically fill up to hold a volume of fluid about the size of a single cell. And as they’re uniform in size, they are ideal to carry out repeatable chemical reactions. This is a fundamental requirement in biological research and health diagnostics.”

Stable emulsion pods

An emulsion is the combination of two liquids that are unmixable, such as oil and water. When mixing oil and water, there may be a brief period of time where the two components are genuinely mixed (this is the emulsion phase), but they soon separate and the oil tends to clump together in pods rather than being uniformly distributed in the water. The 3D printed micro-test tubes are ultimately intended as “armored emulsions”, keeping otherwise unmixable components uniformly distributed within each other for extended periods of time.

Before any printing could take place, however, the team first had to mathematically model the geometry of the structures, their surface properties, and how these parameters interact with volumetric fluids. Then, using the team’s own UV-based microprinting approach, the structures were fabricated and put to the test.

Pharmaceutical and biological research applications

Each structure features a hydrophobic exterior and a hydrophilic interior, enabling it to capture individual emulsion fluid droplets. As such, the captured fluids allow for chemical reactions to occur in a constricted space, whereby individual cells can be kept alive and studied in their own pods. For example, cell samples can be observed to identify certain characteristics, such as enzyme production levels or drug resistances. Since the volume being observed is so small, reaction products can accumulate to significant levels in just a matter of hours, potentially speeding up drug trials or health diagnostic experiments.

Beyond just providing a stable shell for the emulsion within, the structures can also be used as identification tools themselves. Their surface chemistries can be modified to target certain disease markers, all while giving off unique chemical signals, almost like a barcode.

Di Carlo adds: “We think this new ‘lab-on-a-particle’ approach shows promise to leapfrog previous ‘lab-on-a-chip’ systems by eliminating the need for complex pumping and control systems. Making and using the armored emulsions are both quite easy with commonplace laboratory equipment like pipettes and centrifuges. This could allow more research labs around the world to conduct impactful research without significant investment in equipment.”

Further details of the study can be found in the paper titled ‘Monodisperse drops templated by 3D-structured microparticles’. It was written by Chueh-Yu Wu, Mengxing Ouyang, Bao Wang, Joseph de Rutte, Alexis Joo, Matthew Jacobs, Kyung Ha, Andrea L. Bertozzi, and Dino Di Carlo.

With the development of micro and nano-printing techniques, scientists have been able to gain insights and invent systems that would otherwise be impossible. A team of researchers from the University of Grenoble recently developed a new way of 3D printing microstructures with deformable magnetic fields. The team’s novel technique involves adding magnetic microbeads to a standard two-photon polymerization (2PP) 3D printed object, creating nano-tweezers that could only be operated using an external magnetic field.

Elsewhere, researchers from Leiden University recently used 3D printing to produce complex microswimmers and other structures at the micron scale. The structures, which resemble spiky spheres, boats, and spaceships, can be used to study the swimming mechanisms of various species of bacteria in water.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

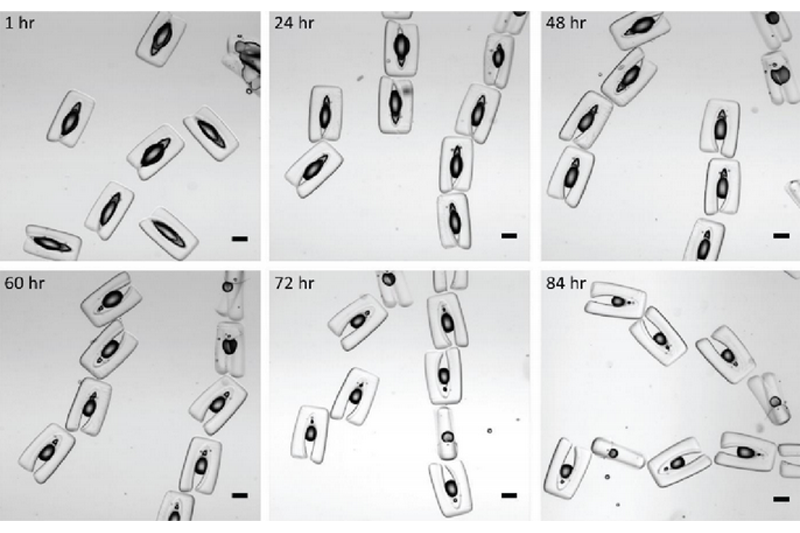

Featured image shows the level of emulsion fluid maintained in the 3D printed structures over time. Image via UCLA.