Engineers from the University of California, Los Angeles (UCLA) have received a $1.5 million grant from the National Science Foundation (NSF) to develop environmentally-friendly 3D printable concrete.

As the most popular construction material in the world, developing a more sustainable alternative to concrete, and being able to apply it with new technology-driven methods, could help dramatically cut its carbon footprint.

“This grant allows us to leverage recent developments in artificial intelligence and machine learning to design a more sustainable product,” comments Mathieu Bauchy, a computational materials scientist and an assistant professor of civil and environmental engineering at the UCLA Samueli School of Engineering.

“We aim to help construction—a conservative, empiricism-based industry— evolve into a knowledge- and data-intensive industry of the 21st century.”

A concrete solution

According to Professor Bauchy, the principal investigator of the grant, the current process to make cement accounts for about 8% of global man-made carbon emissions. As part of NSF’s Designing Materials to Revolutionize and Engineer our Future program, this grant will enable the development of an alternative method that will reduce such pollution by approximately 60%.

The UCLA team will first work to understand and control how slurries of cement flow, and how to make this suitable for 3D printing. The process of maximizing the amount of carbon dioxide incorporated into cement will be then explored. In a third and final step, machine learning will be used to find lightweight 3D printed structures with high load-bearing capabilities.

Concrete’s carbon footprint

Other efforts to improve concrete’s carbon footprint have included a project by the U.S. Army Corps of Engineers (USACE). This patented concrete composition helps limit concrete wastage caused by the material’s tendency to clog in machinery. Pennsylvania State University (PSU) also recently received $75,000 to develop its 3D printing concrete system. Using their experience in NASA’s 3D Printed Mars Habitat Challenge, the PSU team are also designing high-performance, sustainable concrete with a new cement-based mixture to be used with their six-axis robotic additive manufacturing machine.

Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for more additive manufacturing news.

Join our 3D Printing Jobs to post a job or advance your career in 3D printing now.

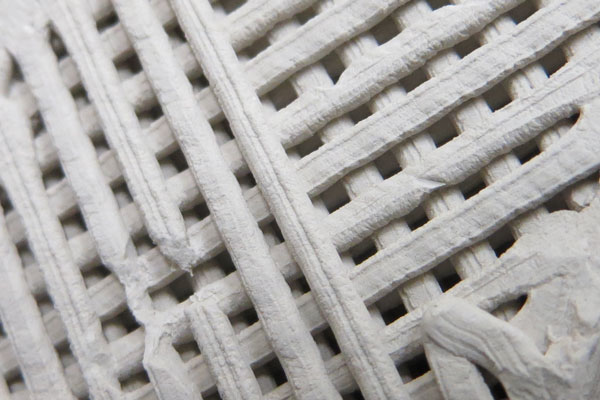

Featured image shows prototype samples of 3D printed concrete. The cube is about 1 square inch in volume. Photo via UCLA.