3F Studio, a German-based design studio, is developing a 3D printed façade destined to serve as the new entrance of the Deutsches Museum in Munich.

As a spin-off from the Technical University of Munich (TUM), the founding members of 3F Studio, Moritz Mungenast, Oliver Tessin and Luc Morroni, implemented traits of the research project, Fluid Morphology, a multifunctional, translucent 3D printed façade application, developed at the Associate Professorship of Architectural Design and Building Envelope.

The computational-based design process allows for “environmentally informed architectural design” and integrates functions such as ventilation, insulation, and shading.

3D printing low-tech building façades

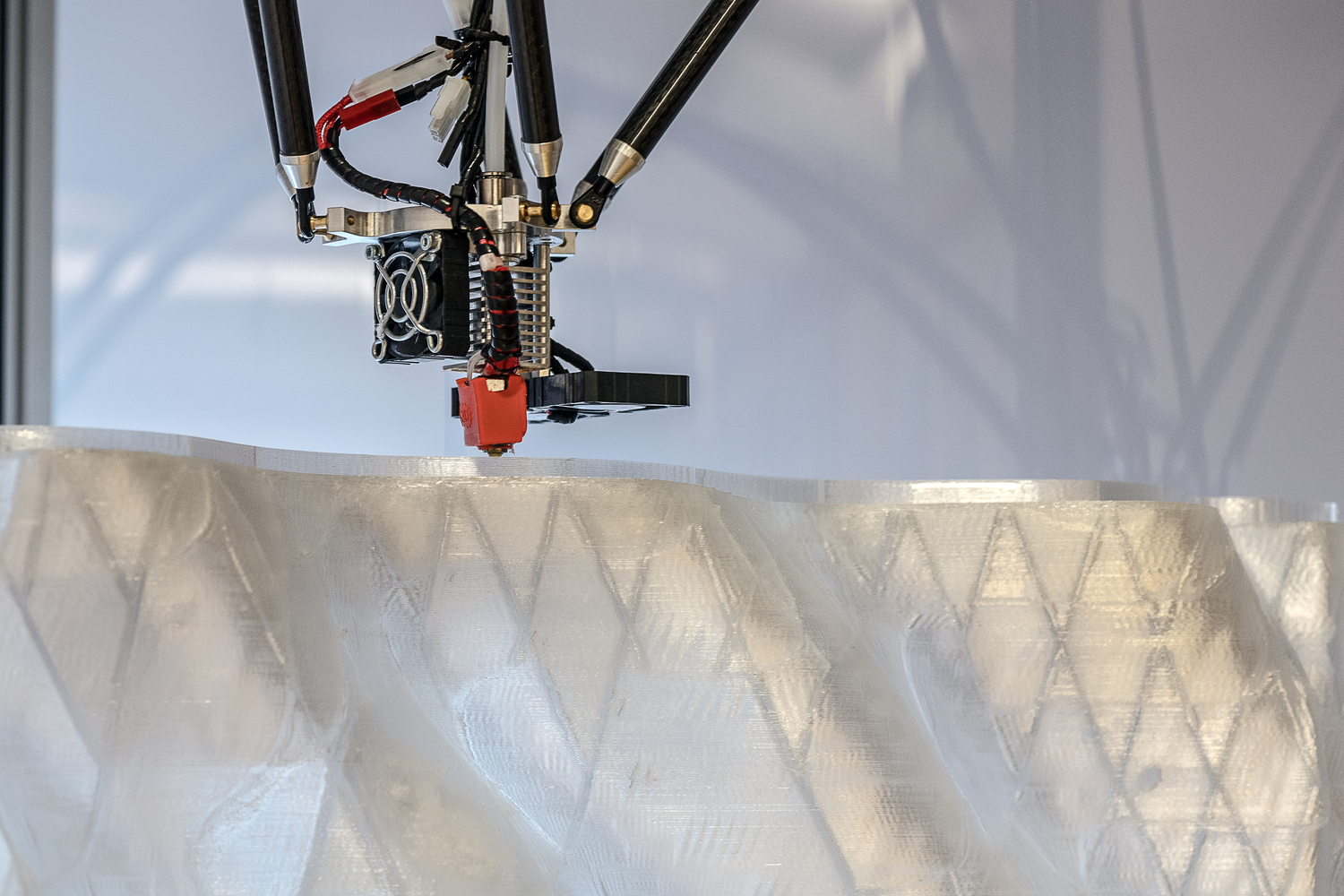

According to Tessin, “One façade element, measuring approximately 1x1m, strikes a snow-white, delicate aesthetic with light shining diffusely through the surface. Within the material, elongated cells provide stability and air-filled cavities for insulation, while thin tubes circulate air for ventilation.” Furthermore, the structure’s wave-like form generates bulges to provide shade, while a microstructured surface ensures optimal acoustics.

When incorporated in real life, the low-tech, plastic 3D printed façade is designed to be soft, airy cloth surrounding the building. “Like water waves, the overlapping corrugated surface alternates between bulges and setbacks, varying in thickness to create a wave pattern.”

“The molding of the façade is also open to manipulation depending on the context, with waves arranged to protect the façade from the heat in summer and allow optimum light in winter.”

A 1.6 x 2.8-meter section of the façade is being tested at the main building of the TUM in Munich, where for one year, sensors will collect data to help architects improve the design before making another prototype in polycarbonate.

A world first?

When applied to the Deutsches Museum’s architecture, the whole façade will measure approximately 45m long and 15m high, with a total weight between 8000 to 12,000 kg. It will also be made from recyclable PETG.

3F Studio imagines the future application of the material in specialist buildings such as museums, libraries, shopping malls, or meeting rooms. At the moment, the studio is planning for the 3D printed façade to be used at the interim entrance for the Deutsches Museum as well as the planning of the entrance building behind the envelope of David Wolferstetter Architektur (DWA) and Architekten Schmidt-Schicketanz und Partner GmbH.

Wolfgang M. Heckl, Director General of the Deutsches Museum comments, “3D printing has always fascinated me personally. Also because it allows you to create completely new, surprising shapes and parts.”

“With Earth’s first 3D printed façade, we could even make the latest technologies widely visible.”

In January 2019, the museum was awaiting the approval and the support of sponsors for the construction of the gateway.

To stay updated with the latest additive manufacturing news, subscribe to the 3D Printing Industry Newsletter, follow us on Twitter, like us on Facebook.

Furthermore, for the latest opportunities in the additive manufacturing sector, join 3D Printing Jobs.

Featured image shows an illustration of a finished building facade. Image via TUM.