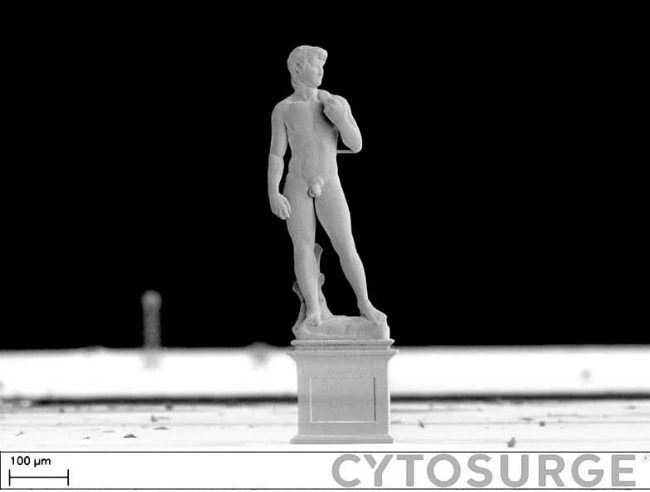

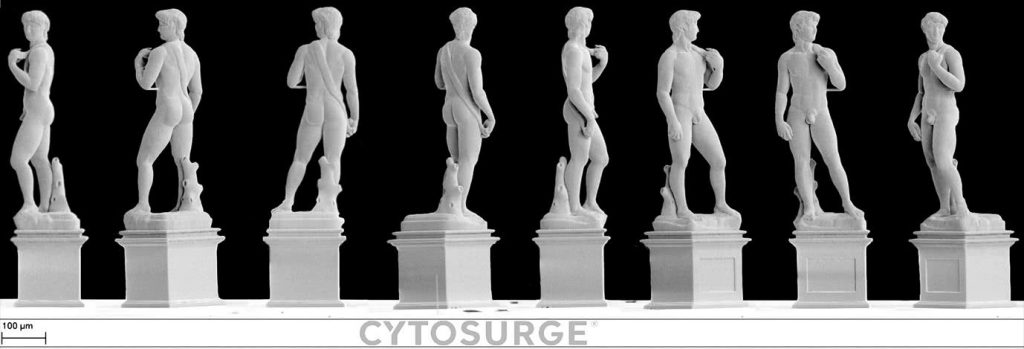

Swiss micro 3D printing company Cytosurge has recreated Michelangelo’s David at a scale comparable to the width of just seven human hairs. Measuring approximately 200 x 200 x 700 µm (L x W x H), this micro masterpiece is actually the largest object the company has ever 3D printed.

It was made to test the abilities of the Cytosurge FluidFM® µ3Dprinter, and has led to some important discoveries for the 3D file preparation process at the company.

Dr. Giorgio Ercolano, R&D Process Engineer of 3D Printing at Cytosurge AG and Microlangelo architect, says:

“It is more than just a copy and downsized model of Michelangelo’s David.”

David vs Goliath

Cytosurge FluidFM® 3D printing technology is primarily used to 3D print using metal. It is a type of electrodeposition process, relying on a chemical reaction between inks containing metallic particles and their contact with the print bed, which acts as an electrode. The method was invented by a team of researchers at ETH Zurich, who span out to create the commercial entity Cytosurge in 2009.

Theoretically, FluidFM® technology can also be applied to create minute polymer and composite material structures. Thanks to a recent upgrade, in addition to creating entirely new structures, the µ3Dprinter can be leveraged to add new structures to pre-fabricated parts.

Cytosurge’s David homage is made from copper. It is hollow, and took just under 12 hours to build. The original David, by helpful comparison to its tiny tribute, is carved from solid marble, and took Michelangelo around 4 years to complete. It stands 5.17 m tall, making the micro version around 0.014% the size of the original, and weighs 6,000 kg, compared to dinky David’s 10 µg (1×10-5 g).

Making of Microlangelo’s David

The digital model used to make Microlangelo’s David was sourced by Cytosurge from gabrielmda on Blend Swap, under public domain and creative commons licensing. As an opensource file, and not created by the Cytosurge team itself, the model could have proved challenging to print on the company’s advanced hardware. As Dr. Ercolano explains however, “Our deep understanding of the printing process has led to a new way of processing the 3D computer model of the statue and then converting it into machine code. That’s what makes the new David statue so extraordinary.”

“This object has been sliced from an open-source CAD file and afterwards was sent directly to the printer. This slicing method enables an entirely new way to print designs with the FluidFM µ3Dprinter.”

Another creative idea recently explored by Cytosurge was Professor Kokichi Sugihara’s “impossible objects.” Optical illusions, the smallest of these objects is smaller than 100µm long.

Vote now for your Creative Application of the Year and more in the 2019 3D Printing Industry Awards. For all of the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Join 3D Printing Jobs to find your next opportunity.

Featured image shows a 360 view of Micro David. Photo via Cytosurge