This week 3D Printing Industry visited King’s College London (KCL) in London Bridge for the SPARE PARTS: Rethinking Human Repair exhibition. Here, art, science, and new technologies meld together to explore methods of creating body parts and that can live independently from the human anatomy.

Located at KCL’s recently established Science Gallery London, the SPARE PARTS exhibition presents a 3D bioprinted voice box, additively manufactured hearts, as well as body part simulations as far as the artificial eye can see.

The following shows two art-pieces among the 16 designers which integrate 3D printing to convey continuous human life. Stéphanie Delcroix, the curator-producer for SPARE PARTS explained, “The thought-provoking artworks featured within SPARE PARTS attempt to challenge preconceptions around the repair of the human body.”

“This exhibition offers unexpected perspectives and striking visual metaphors that describe the technological and scientific advances that can restore our bodies and sustain human life.”

Big Heart Data

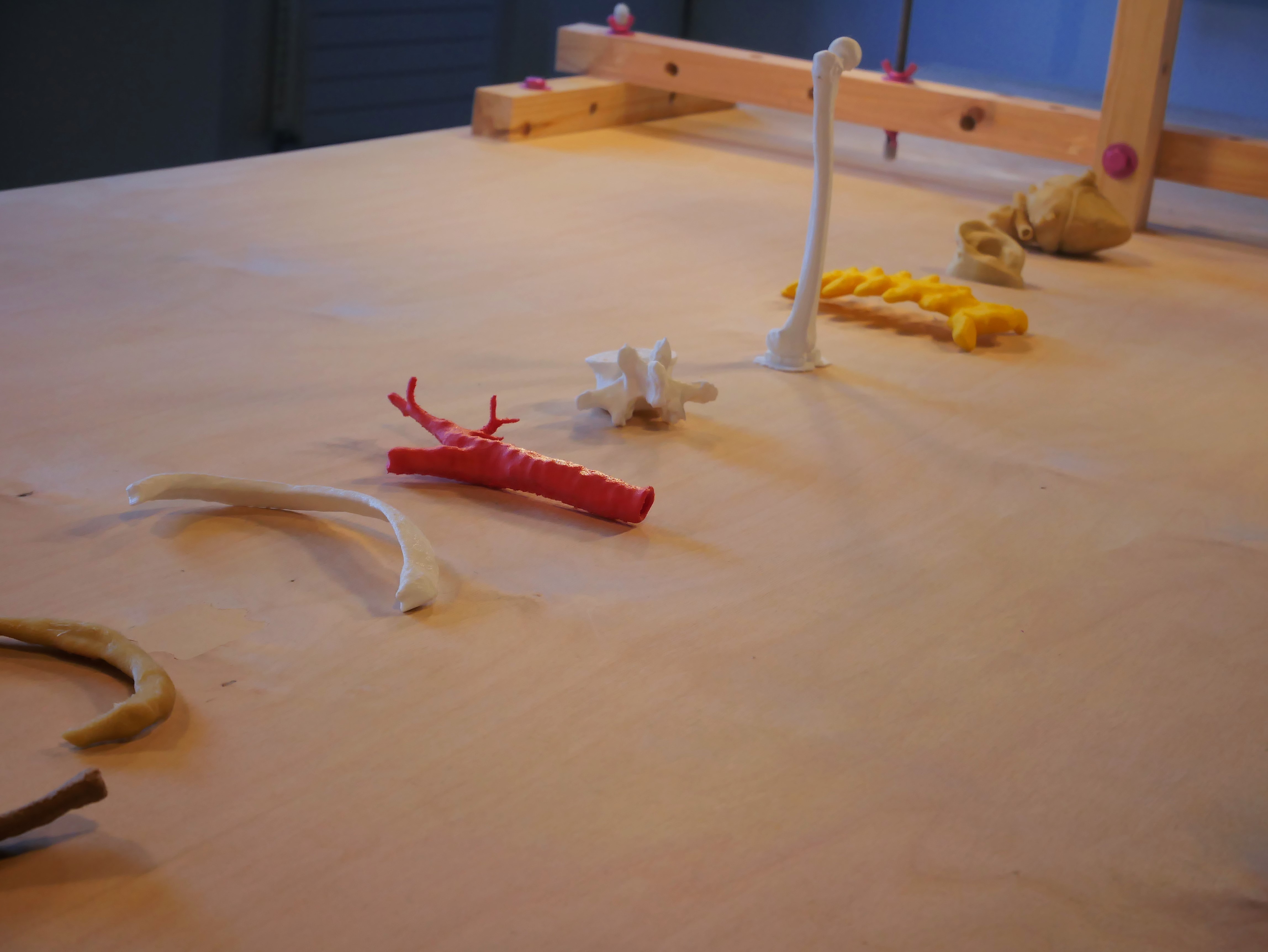

Salomé Bazin, a multi-disciplinary designer and founder of Cellule, a London-based collaborative design studio, and Pablo Lamata of KCL’s Department of Biomedical Engineering, have created the Big Heat Data exhibit which produces customized 3D printed hearts.

This piece aims to physically realize the changes in both healthy and ailing hearts. Bazin told 3D Printing Industry:

“I think we really underestimate the importance of a patients readiness before heart surgery. 3D printed anatomical models seem to be only produced for extreme cases with the surgeon’s use at the forefront.”

“I wanted to create a system where the individuality of organs is presented to the patients themselves. They will be able to hold, frame, and keep their own heart – whereas before, they could only keep an image or sketch from a hospital. That’s why we chose the accessible technology – FDM 3D printing.”

According to Bazin, each heart took three hours to 3D print using PLA. Furthermore, Batch.Works, a London-based 3D printing service bureau, was commissioned to produce the models.

“The medical research team had the CT scans and data, then, I had to do the surface modeling for the hearts. We also had to get creative with the slicing to get the aesthetic we wanted,” added Bazin. “Our software also allows the visualization of a growing heart. The patient can see how their heart would look with certain variables such as age and muscle thickness. This shows the heart’s potential progression from birth to adulthood.”

New organs of creation

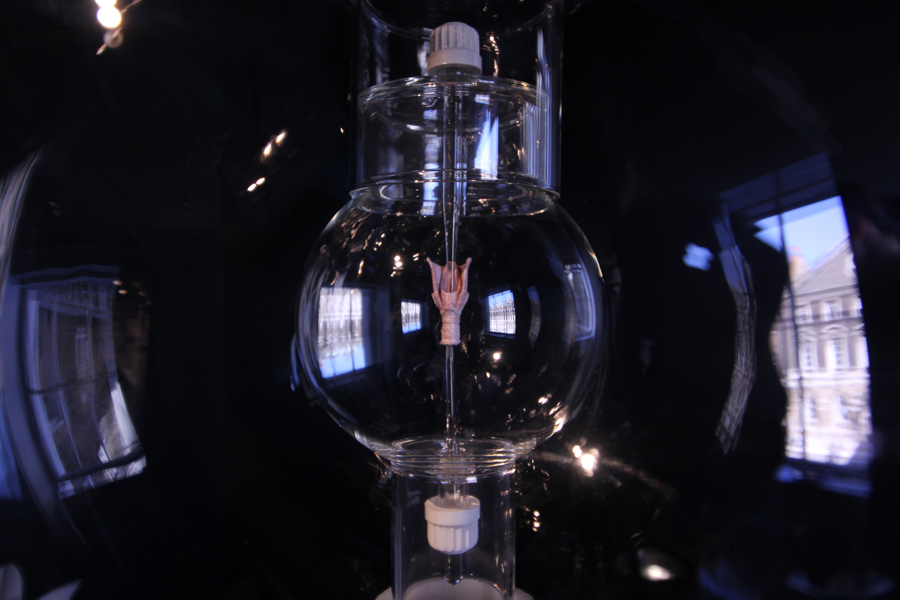

Another London-based art and design studio, Burton Nitta, collaborated with Lucy Di-Silvio, Professor of Tissue Engineering and her team at the Department of Tissue Engineering and Biophotonics, KCL, for the New Organs of Creation exhibit.

This piece presents a hypothetical human larynx, or voice box, designed to have low sound frequencies in the range of 50Hz to 100Hz. Professor Di-Silvio explained that this range “can encourage the formation of stem cells for tissue regeneration.”

“We took inspiration from the koala; it appears a to just be a small animal but many are not aware of its animalistic call which uses very low pitch vocalizations. This is done as koalas possess an extra pair of vocal folds outside of the larynx, where the oral and nasal cavities connect.”

Impressed at the 3D bioprinted model, Professor Di-Silvio made sure to clarify that this model was 3D printed using FDM/FFF, then covered with the cells and colored to depict the larynx.

“3D bioprinting is an exciting task for us, but the scaffold of the larynx was 3D printed in plastic with Dr. Trevor Coward from the Faculty of Dentistry, Oral & Craniofacial Sciences at King’s College London. We’ve been anticipating the arrival of our ROKIT INVIVO bioprinter from Korea, which will push our research even further.”

A 3D printing anatomical workshop

KCL students are also hosting a 3D print open source body parts workshop within the SPARE PARTS exhibition. Dubbed as the Synthetic Anatomy & Biotechnology exhibition, this workshop is not only educating other KCL students on how to 3D print but showing how it can be applied within bioengineering.

Science Gallery London‘s SPARE PARTS exhibition is open to all until May 12th, 2019.

Remember, time is running out; Nominate for the upcoming 2019 3D Printing Industry Awards.

For further awards updates and ideas for who to nominate this year, subscribe to the 3D Printing Industry newsletter, follow us on Facebook and like us on Twitter.

Seeking 3D Printing Jobs? Join and advertise on our dedicated site now to reach professionals in this industry.

Featured image shows the exterior of the Spare Parts Exhibition in London. Photo by Tia Vialva.