3D Printing Industry is taking an in depth look at how additive manufacturing is moving to production. Over the coming weeks the results of interviews with industry leading practitioners will be published.

This article is part of a series examining Trends in Additive Manufacturing for End-Use Production.

Ramon Pastor is vice president and general manager, HP Multi Jet Fusion. HP Jet Fusion 3D 4200/3200 award winning 3D printing solutions are designed for industrial prototyping and final part production environments.

3DPI: What is your percentage estimate of how much your printers are used for production versus other applications?

Ramon Pastor: Currently, Multi Jet Fusion printers are used for production over 50% of the time vs. prototyping only, a figure we expect to grow significantly. For example, companies like Forecast 3D, one of the largest privately-held printing service providers in the U.S., are already using Multi Jet Fusion for full-scale 3D production, with a process that’s 10x faster and half the cost of traditional methods. Well over 500,000 parts have been produced with Multi Jet Fusion since its launch.

3DPI: Do you have an estimate of the addressable market for AM in production?

RP: 3D printing is spearheading a digital industrial revolution that will completely transform the $12 trillion global manufacturing industry, forever changing the way we conceive, design, produce, distribute nearly everything.

3DPI: Which industries/verticals are leading in the use of AM for production?

RP: We see accelerating adoption of 3D printing across all major industries, most notably automotive, aerospace, consumer goods, and medical technology, with great promise in additional sectors like heavy industry.

3DPI: What barriers does AM face for production and how are these surmountable?

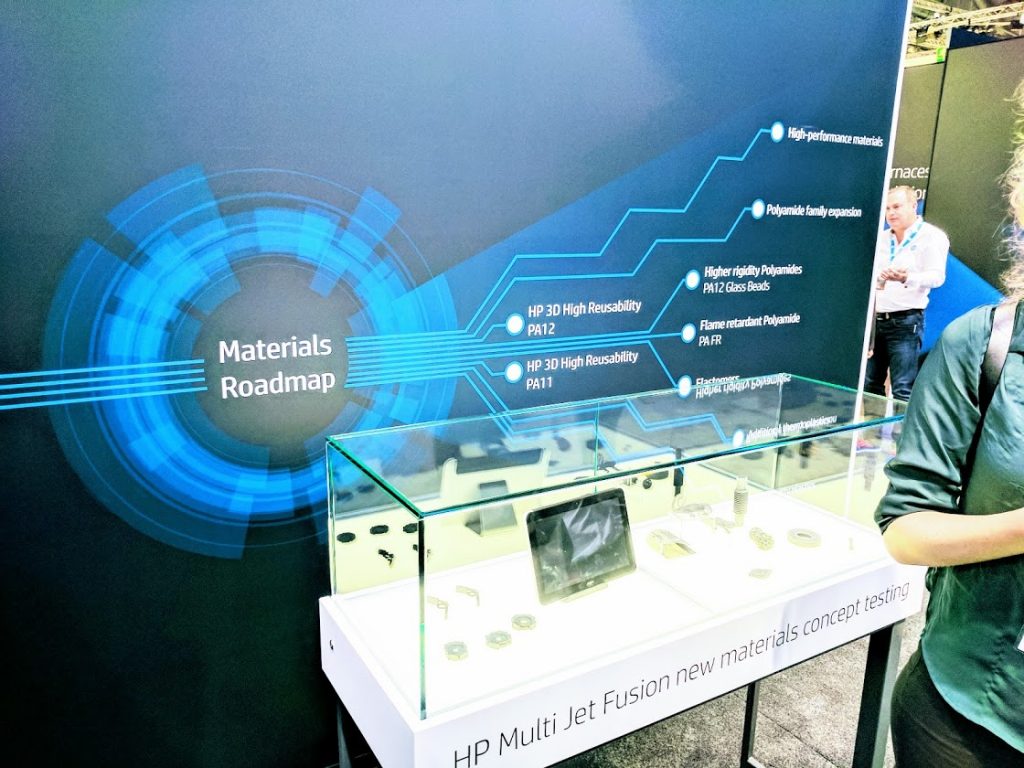

RP: We see six keys to unlocking the full potential of 3D printing to transform the $12 trillion global manufacturing industry: World Class Product and Technology Capabilities, Open Materials Platform to Drive Down Costs, Materials Diversity, New Design Methods for Additive, Reinvention of Supply Chains, and Regulations and Standards.

At HP, we’ve already made big advancements on all fronts, particularly in lowering costs and accelerating innovation with our unique open materials platform model, but this digital manufacturing revolution has only just begun.

3DPI: Are there any notable trends in AM for end use production?

RP: Currently: personalization, last moment differentiation, distributed manufacturing, shorter response time and flexibility to changes in design, forecast or mix.

3DPI: Can you name any specific case studies where AM is used for end use production?

RP: Specific use cases are confidential to our customers, but Multi Jet Fusion is used extensively to produce HP’s own 3D printers. And as previously mentioned, Forecast 3D recently became the first service bureau to offer full-run, high-volume 3D production manufacturing with the volume installation of 12 Multi Jet Fusion printing units.

This article is part of a series examining Trends in Additive Manufacturing for End-Use Production.

You can read more about HP Multi Jet Fusion here.

If you found this insight useful, then subscribe to our newsletter and follow us on social media.