Fincantieri Australia, a localized branch of international shipbuilding company Fincantieri has signed a 12-month Memorandum of Understanding (MoU) with industrial metal additive manufacturing company Titomic.

Within this new MoU, Titomic will asses the potential of its Titomic Kinetic Fusion metal 3D printing process applied to Fincantieri’s existing manufacturing facilities.

“This agreement with Fincantieri marks a significant milestone for future shipbuilding and industrial scale additive manufacturing,” comments Jeff Lang, CEO and CTO of the Australian AM company.

“Titomic’s signing with Fincantieri to evaluate our Titomic Kinetic Fusion process will not only add value to existing manufacturing and repair activities, it will lead to the creation of next generation high tech vessels.”

Titomic Kinetic Fusion

Based in Australia, Titomic has the exclusive rights to a titanium cold-spray technique developed and patented by the Australian Government’s Commonwealth Scientific and Industrial Research Organisation (CSIRO).

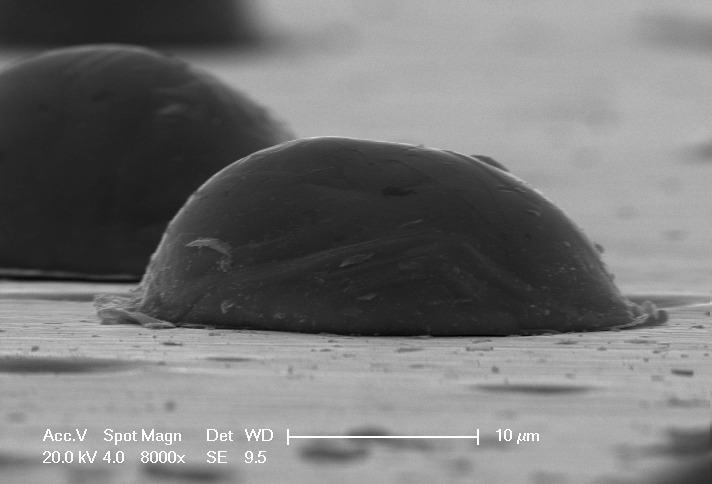

Unlike laser based technologies, in cold-spray metals are not melted in the deposition process. Instead, Titomic Kinetic Fusion relies on a supersonic gas jet to fire particles at high speed and fuse to a surface on impact. This makes it easier to combine dissimilar metals to make a part.

According to Titmoic the process can “Manufacture at 30x faster than commercial 3D printers without size constraints.”

SEM image of a cold sprayed titanium particle bonded to steel surface. Image via Wikimedia Commons/Thshoeb

Underwater additive

As of 2013, Fincantieri is the largest shipbuilder in Europe, and this year the Fincantieri group doubled in size to become the fourth largest in the world.

The company makes both commercial and military vessels and is on a shortlist alongside BAE Systems and Navantia to build a future class of frigates for the Royal Australian Navy. Scheduled to begin in 2020, the contenders are still undergoing competitive evaluation.

In the additive manufacturing sector, BAE has a great deal of experience, especially with aerospace applications. Navantia meanwhile has commenced trials of 3D printed parts for its supertankers.

With the industrial capabilities, Titomic and Fincantieri together could become contenders in the large-scale marine additive space, alongside the popular wire arc additive manufacturing (WAAM) process used by DAMEN Shipyards and Huisman.

Making the Australian Navy a high-tech world leader

Concluding the statement on the Titomic MoU Dario Deste, Chairman of Fincantieri Australia said, “We are pleased to partner with Titomic, an innovative advanced manufacturing company, to pursue new technological development, continuous improvement and value creation for all our stakeholders.”

“The significance of this partnership examines how we can introduce new manufacturing technologies to make Australia sovereign in advanced naval technology and improve our solutions on the world-wide market.”

Stay up to date with all the latest 3D printing business news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking to start your career in this new and rapidly changing industry? Sign up to 3D Printing Jobs here.

Featured image shows visuals used in the Australian Future Frigates SEA 5000 program. Image via Fincantieri