Christmas has come late for the new owners of a couple of high-end additive manufacturing systems.

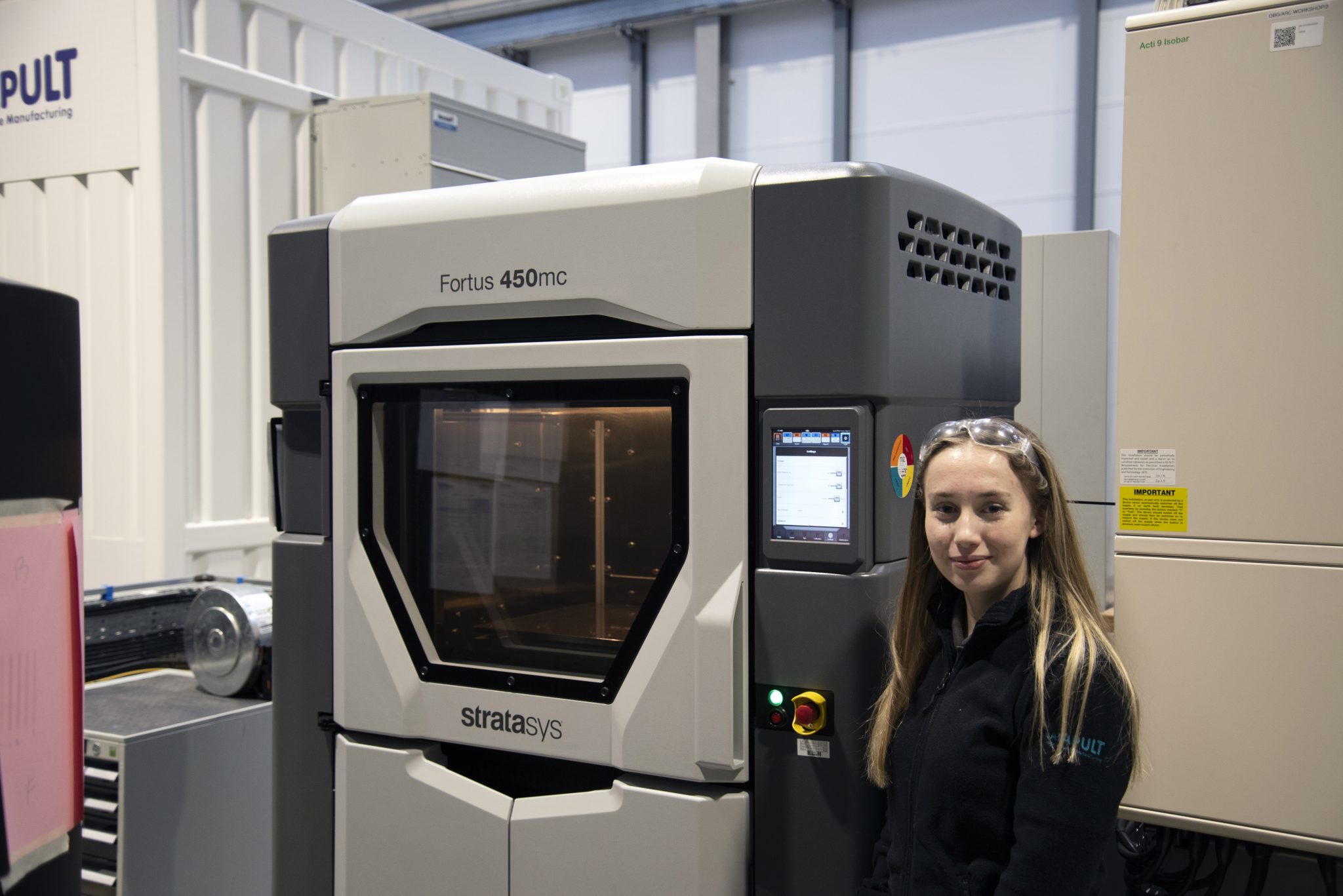

Firstly, the Manufacturing Technology Centre (MTC) in Coventry, UK, has installed a Fortus 450mc 3D printer from Stratasys to meet demanding production applications throughout the country. Hoda Amel, a Senior Research Engineer at the MTC, stated:

“Adding an FDM-based solution to the line-up is a natural evolution as we look to expand our production-grade additive manufacturing capability to develop early-stage new solutions for UK manufacturers that can then be passed on to the supply chain.

“We now have access to a wide range of high-performance thermoplastic materials that enable us to explore multi-composite parts and complex tooling for engineering applications.”

The MTC and Stratasys

In 2017, the MTC commenced its partnership with Stratasys in 2017 which enabled the center to utilize its portfolio of 3D printing technology for tooling and complex end-use parts, including the Objet1000. As the latest installation at the MTC’s National Centre for Additive Manufacturing, the F450mc is also supporting the replacement of aluminum tooling with rapid prototyping in the robotics and automation department.

Yann Rageul, Strategic Accounts Director at Stratasys, explained, “The MTC’s latest investment expands their ability to deliver more value when addressing specific demands across more and more traditional production applications on behalf of those operating at the coal-face of UK manufacturing.”

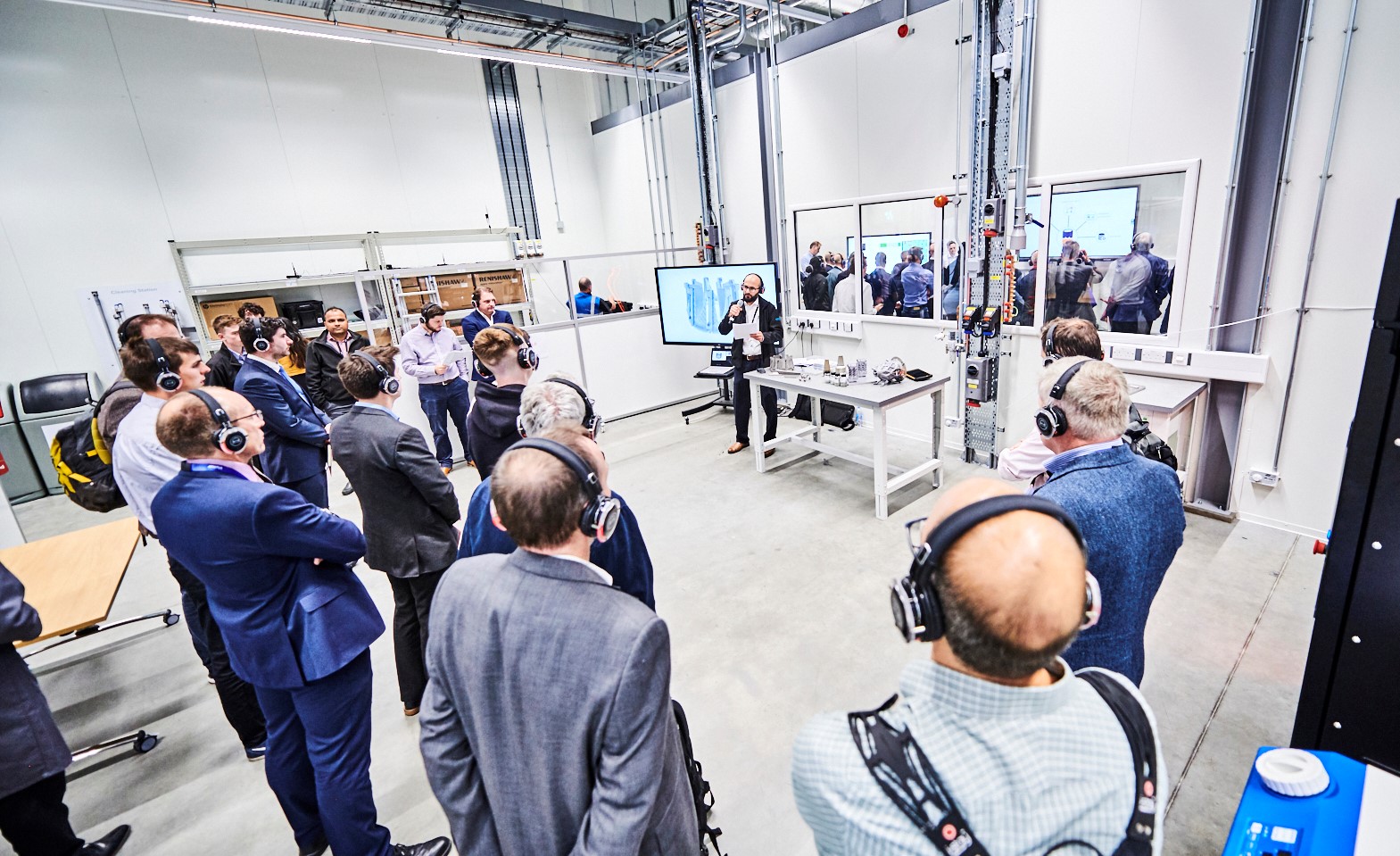

Prior to this, the MTC opened a new innovation hub for metal additive manufacturing. Marking a new stage for the award-winning DRAMA project, the facility acts as a physical testbed for the integration of full, digitally-linked, 3D printing process chains in the aerospace sector.

Nordmetall purchases GEFERTEC arc403

In Hamburg, Germany, Nordmetall, a metal, and electrical solutions provider, has purchased an arc403 additive manufacturing system from GEFERTEC, the developer and provider of 3DMP metal 3D printers and technology for dynamic material testing. This will advance the development of components made with high-strength steels.

Presently, the company is involved in several research and development projects aimed at advancing technologies using such parts. The arc403, which enables five-axis processing, will allow them to produce larger amounts of steel components at a lower cost for its customers.

“We work on many customer projects that include components made from high-strength steels – and build-up welding is one of our standard manufacturing techniques,” said Dr. Norman Herzig, CEO of Nordmetall. “Now, with our new arc403, we can automate this process instead of relying on manual operations.”

For more business updates in 3D printing, subscribe to our 3D printing newsletter and join us on Facebook and Twitter. Looking for a job? Visit our 3D Printing Jobs board.

Featured image shows the Nordmetall logo printed on a GEFERTEC arc 403. Photo via GEFERTEC.