The first GEFERTEC Arc403 metal 3D printer has been installed in Poland at the Institute of Non-Ferrous Metals (Instytut Metali Nieżelaznych/IMN).

With this system, GEFERTEC, the German-based developer and provider of 3DMP metal 3D printers and technology, will further IMN’s development and refinement of industrial additive manufacturing batch materials for the aerospace and automotive sectors.

“The arc403 machine and its 3DMP process provide us with an excellent opportunity to further investigate the AM process and to design new materials of controlled mechanical and physical properties,” said Barbara Juszczyk, Managing Director of the IMN.

The Institute of Non-Ferrous Metals

The IMN has been active for decades; its work covers all stages of metallic materials production. This begins includes ore treatment, the process of separating commercially valuable minerals from its rock or sediment, as well as technologies for the manufacturing of modern products.

The various solutions developed at the IMN were developed for industries using non-ferrous metals, i.e., metals including alloys that do not contain significant amounts of iron. The facility also includes modern testing and measurement instruments and has laboratories and pilot installations for material processes such as phase separation, enrichment, and synthesis and chemical analysis.

As the latest edition to IMN’s equipment, the Arc403, and its large-scale wire-arc additive manufacturing technology (known as 3DMP) will test the viability of new materials. Tobias Röhrich, CEO of GEFERTEC, stated:

“We are delighted to have won the IMN as a new client since their R&D of innovative batch materials is paramount to 3DMP and the broad range of industries it serves.”

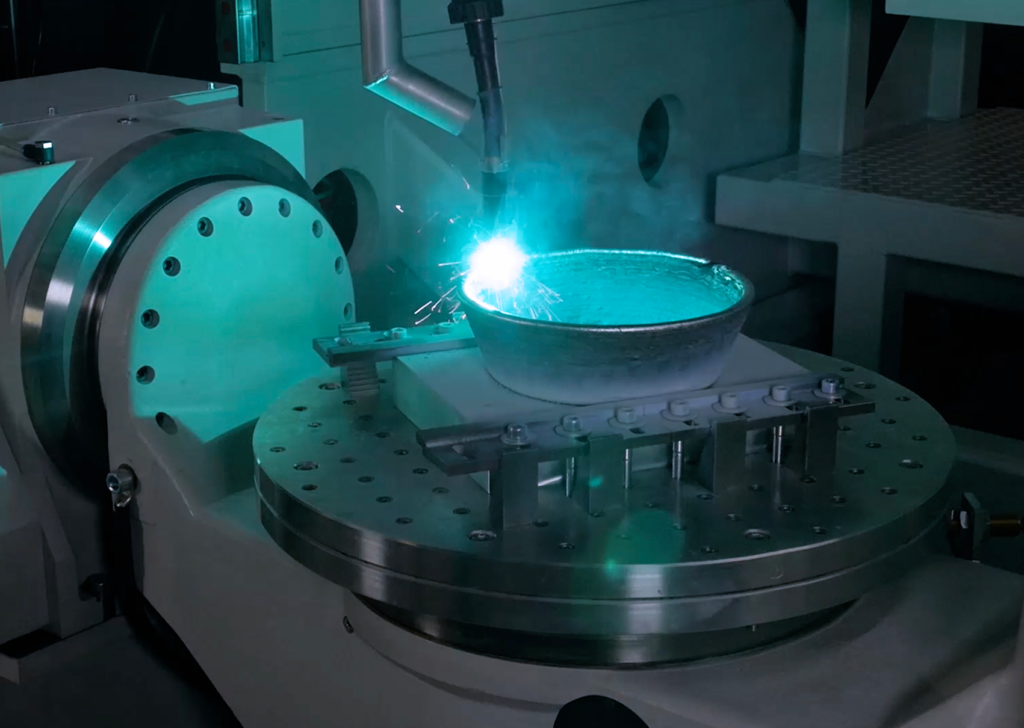

Wire-arc additive manufacturing

The Arc403 system enables five-axis processing for components of dimensions up to 800mm – 900mm -1000mm in x-y-z and 800 kg mass. Also in the company’s portfolio is the Arc603, a 3-axis machine capable of creating components up to 3 m³, with a maximum mass of 3000kg and the Arc605, a 5-axis machine with a maximum capacity of up to 0.8 m³ and 500 kg mass.

Operating with 3DMP, GEFERTEC states the technology promises to eradicate waste with “nearly 100% material utilization,” and cost savings of “up to 60% versus conventional manufacturing.”

Prior to this installation, the company partnered with Linde Group, a Munich-based chemical company, to investigate process gas and oxygen within metal additive manufacturing.

For more of the latest 3D printing news, subscribe to the 3D Printing Industry Newsletter, follow us on Twitter, like us on Facebook.

Furthermore, join 3D Printing Jobs for opportunities in additive manufacturing.

Featured image shows the GEFERTEC 3DMP additive manufacturing process. Photo via GEFERTEC.