3D printed titanium components are favored in aerospace, medical and automotive industries for their high strength to weight ratio. However, a new metal powder composition from the Russian National University of Science and Technology (NUST) MISiS aims to match these properties with components made from aluminum.

In a recent study, published online in the journal Sustainable Materials and Technologies, NUST MISiS researchers detail the production of an ultrahigh-purity alumina (UHPA), that doubles the strength of 3D printed aluminum composites.

Additive manufacturing using ultrahigh-purity alumina

The NUST MISiS team’s research uses aluminum granules with a purity of 99.7%. Via oxidation, alkali and acid treatment and thermal calcination at 1450 °C, the granules are turned into an aluminum hydroxide.

At each stage of the process, researchers take a reading of the oxide’s impurities, particularly iron and potassium impurities which proved to be the most problematic. With this data, the team then modify chemical treatments, washing and calcination, resulting in a UHPA with purity 99.99% and 99.999%.

Double the strength

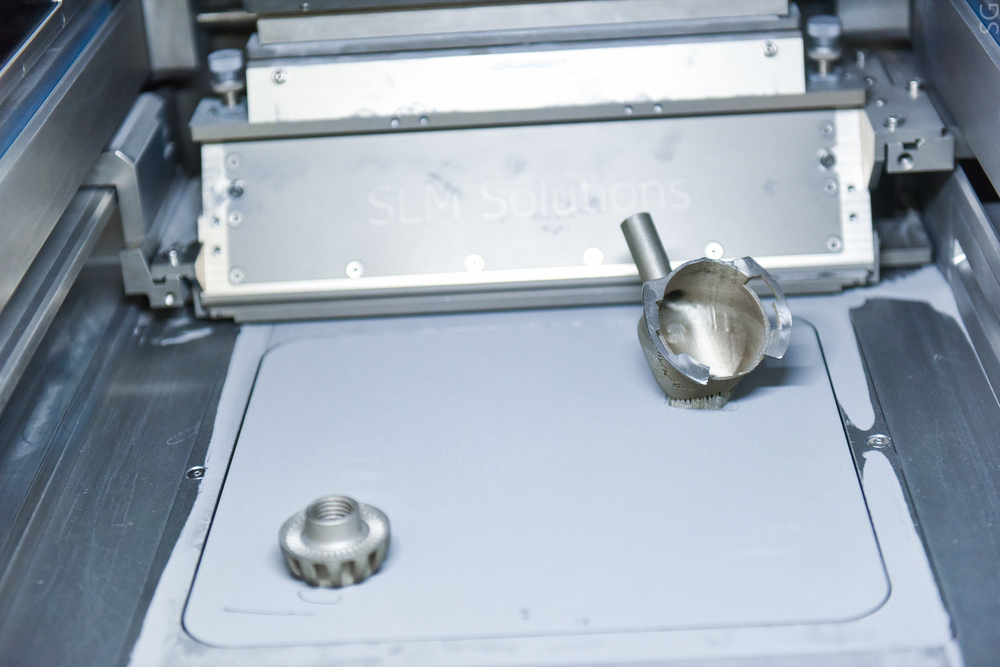

While optimal processing conditions are still to be determined for the powder, the NUST MISiS team is already using the material to develop 3D printed prototypes using selective laser melting.

“We have developed a technology to strengthen the aluminum-matrix composites obtained by 3D printing, and we have obtained innovative precursor-modifiers by burning aluminum powders,” explains Professor Alexander Gromov, research team led from the NUST MISiS Department for Non-Ferrous Metals and Gold.

“It is the special properties and structure of the surface that allows the particles to be firmly attached to the aluminum matrix and, as a result, [doubles] the strength of the obtained composites.”

Titanium is roughly 6 times stronger than aluminum, so this process produces composite a third of the superior metal’s strength.

Low-cost metal 3D printing

One of the main advantages of this UHPA powder production method is that it is low cost, maintaining a great deal of profitability when applying the material. While material cost is not the primary concern around the industrialization of AM – this is not to say reduced input costs are not worthy of attention.

Metalysis’ patented Fray, Farthing, Chen (FFC) process is one approach to reducing the cost of titanium/aluminum alloys, also in development is scandium processing. And, covering materials, processes, automation and the process chain, Germany’s Fraunhofer Society has launched the futureAM project “to significantly accelerate” and reduce the cost of metal 3D printing.

“Advanced manufacturing process of ultrahigh-purity α-Al2O3” as discussed in this article, is published online in Sustainable Materials and Technologies. It is co-authored by G.N. Ambaryan, M.S. Vlaskin, O. A. Buryakovskaya, S.A. Kislenko, A. Z. Zhuk, E.I. Shkolnikov, A. N. Arnautov, S.V. Zmanovsky. A.A. Osipenkova, V.P. Tarasov and A.A. Gromov.

As a footnote the NUST MISiS website has this to say about the use of Titanium in additive manufacturing, “Titanium is the optimal metal for manufacturing products for the aerospace industry, however it cannot be used in 3D printing because of the fire and explosion hazards of powders.” Surely some mistake?

For all the latest additive manufacturing materials research subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in academia? Create a free profile on 3D Printing Jobs, or advertise (for free) to find expertise in your area.

Featured image shows a knot sample 3D printed prom UHPA powder. Photo via NUST MISiS.