Well, today’s the day that the first smartphone 3D printer has hit Kickstarter. Will this be a day for the history e-books? Given the track record of 3D printing-related crowdfunding campaigns – Formlabs, the 3Doodler, and Wiivv Wearbles – I wouldn’t be surprised if the OLO campaign doesn’t reach its humble $80,000 goal in an hour, let alone a day. After all, the firm behind OLO, Solido3D, is asking $99 for a device that converts your phone into a 3D printer ($79 for early birds).

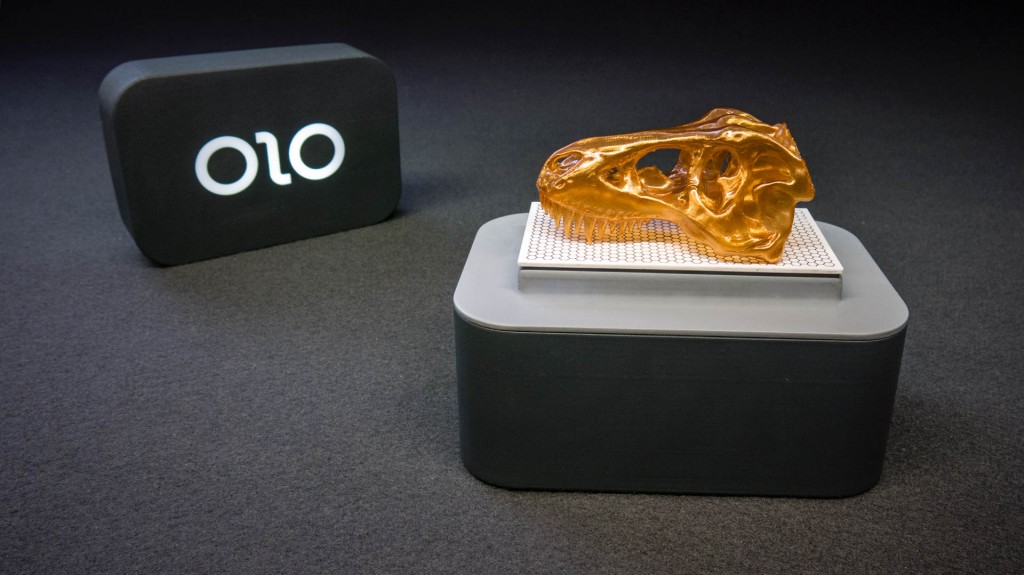

OLO is a uniquely elegant and powerful device. On the one hand, the 3D printer is simple in terms of actual mechanics. Seven components, including the injection molded shell and a single Z-axis motor, make up the printer itself. However, by relying on a user’s smartphone (iPhone, Android, or Windows Phone) as the soul of the system, OLO becomes incredibly powerful. Via the OLO smartphone app, masks of light are projected from the phone onto the printer’s resin tray, hardening each slice of an object as the OLO lifts it out of the vat layer by layer. In this way, OLO is almost like the Google Cardboard of 3D printing. It takes an ingenious tool that already exists, the smartphone, and uses it to power an entirely new application that opens up endless possibilities.

Why, then, hasn’t such a device hit the market before? Say, by using existing material for DLP or SLA 3D printers? The key ingredient that makes OLO possible is the resin. Unlike other photopolymer 3D printers, like the Form 2 or the Ember, OLO doesn’t rely on UV resin, which requires lasers or digital UV projectors to power the printing process. OLO relies on a new generation of resins that can be cured by ordinary white light. Developed by industry partners, OLO’s daylight-reactive material can be hardened into a 3D object using an ordinary smartphone.

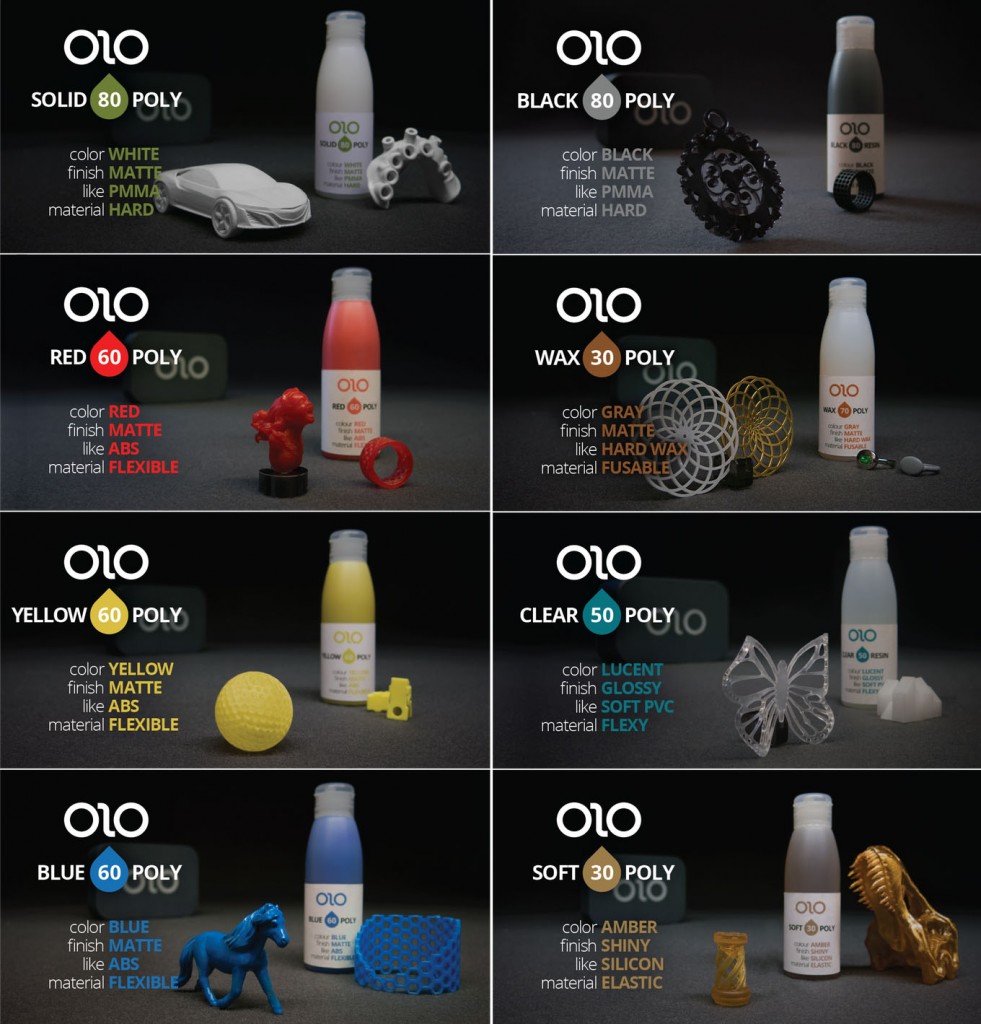

Now, customers can head over to the OLO Kickstarter campaign and purchase OLO, along with packages of this specialty resin, to begin 3D printing in a surprisingly wide variety of materials and colors: hard, white Solid 80 Poly; flexible Red 60 Poly; flexible Yellow 60 Poly; flexible Blue 60 Poly; hard Black 80 Poly; castable, grey Wax 30 Poly; translucent Clear 50 Poly; and the amber, elastic Soft 30 Poly resins. All of the materials can be rinsed under running water to be removed from the print bed. And, as you can tell from these names, OLO already has a pretty large materials portfolio, giving it a number of applications right out of the box, such as creating castable jewelry or flexible prototypes.

Though these industrial applications give OLO the ability to rival high-end machines in the jewelry, dental, and electronics markets, its proposed user friendliness has consumers in mind, as well. OLO runs on four AA batteries and requires no external computer, other than a smartphone, making it completely wireless. Solido3D has even invented the idea of a 3D telegram, in which users can send files to one another that aren’t revealed until they’ve been printed. And its petite size of 6.8” x 4.5” x 5.8” make it portable.

The print volume, though small, is nothing to balk at, however. At 3” x 5” x 2”, OLO prints objects only a bit smaller than the Autodesk Ember, which has a volume of about 2.5” x 1.6” x 5.3”. And it can achieve layer thicknesses as fine as 36 microns (0.036mm), with a resolution of 42 microns (0.042 mm). OLO’s makers say that the device also features auto-leveling and that the flexible build plate makes for easy print removal.

In response to our last article on OLO, readers had some concerns about some of the details about the project, for instance, related to the bottles of resin and the animated .gif used in the marketing materials. I reached out to the the makers of OLO, Filippo Moroni and Pietro Gabriele of Solido3D, to ask them why they had used a translucent bottles in their promos if their resin is daylight-sensitive. As it turns out, this was a marketing choice to showcase the colors of the resins. I learned that, in order to harden the material, the resin must be in close proximity to the light source. Keeping it in a translucent bottle posed no real problem for the video shoot, but for long-term preservation, OLO’s resins will actually be packaged in aluminum canisters.

The animated .gif I used in the previous article also made not have been depicting the 3D printing process as accurately as it should have. The OLO team has since made public a video of OLO actually working with an iPhone 6. Clearly less stylistic than the animated .gif, the video features a cutaway of OLO 3D printing an object and, from the looks of it, there really is no reason to believe that this isn’t the real deal.

Their credibility is further validated by the fact that Solid03D is a part of the larger Fonderie Digitali, a network of Italian businesses that also includes such important and reputable businesses as WASP and D-Shape. So far, it seems like the Solido3D team has been pretty open about the technology, for the most part, so, if you have any questions, I’m sure they’d be happy to answer them.

To me, the most exciting aspect of the technology is the fact that about one-third of the world’s population is already carrying a smartphone around in their pocket. 3D printing has been scoffed at by the likes of Terry Gou, CEO of Foxconn, and others who have called the technology a gimmick and assumed that it won’t make it into every home any day soon. OLO proves, however, that, for just $99, it could very well end up in the homes of anyone who owns a smartphone. As a result, OLO could be among the most democratizing 3D printers to have hit the market recently. Now, we’ll just have to wait for it to leap off of the pages of Kickstarter and into the pages of history.

Update 3/21/2016, 10:26 am PST: As I write this update, about 6 minutes after the project went live, it has already achieved half of its Kickstarter goal. I watched it reach $30K in just three minutes.

Update 3/21/2016, 10:38 am PST: The campaign is almost at its goal with about $15K left to go.

Update 3/21/2016, 10:51 am PST: Ok, so I was wrong about how long it would take for them to fulfill their goal. I’d said an hour when, in reality, it was actually thirty minutes. I have to look into this further, but, I would say that this was the fastest-fulfilled Kickstarter campaign in history? And, if it keeps going like this, I wouldn’t be surprised if it becomes the most fulfilled in history, too.