“guideline” is an answer to those in the medical and clinical 3D Printing community that are constantly asking us for a ISO 10993 class of 3D Printing material.

Unique features over std PETG:

1. Already registered with the FDA

2. Higher Printing temperature than all other PETG’s

3. Very low shrinkage.

4. A thermal profile that accomodates very small printed features without the standard Heat Build-up that distorts most fine details.

5. The thermal profile allows the user to easily print hollow tubes that can be water tight.

6. A manufacturing process that maintains ORP and pH to acceptable levels.

7. excellent use as a support material for medical grade Nylons.

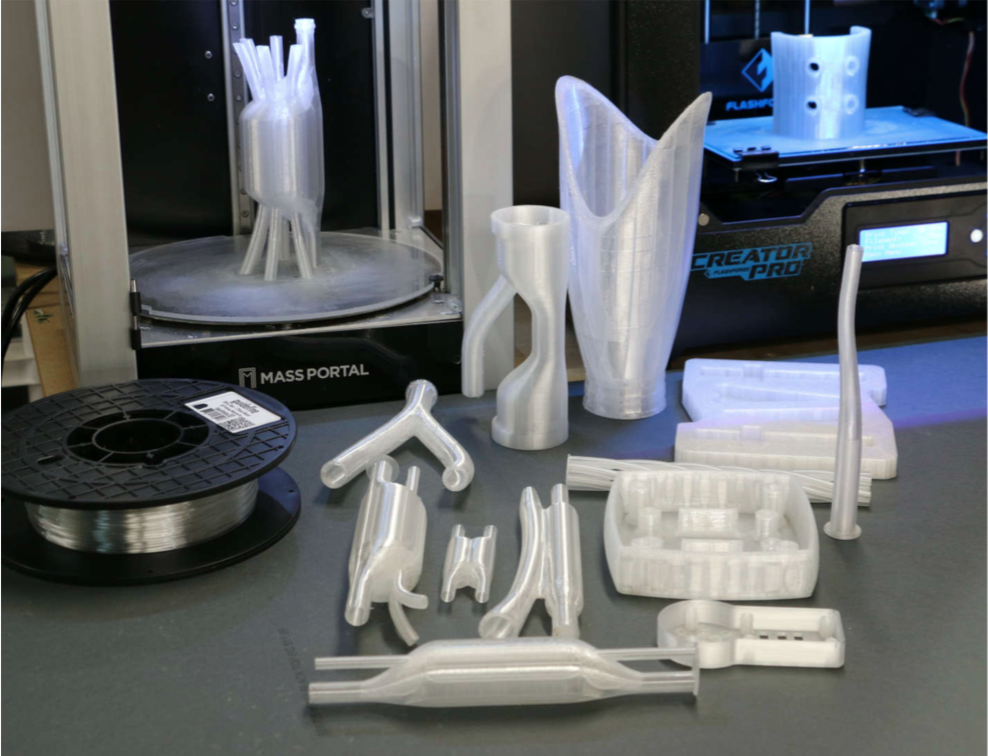

Guidel!ne is a unique high strength PETG based material with excellent high temperature printing capabilities. Users know that printing small features of some parts can be difficult due to thermal build-up. guidel!ne is much less susceptible to these thermal issues allowing for finer detail without distortion. guidel!ne is also released as a starting point for individuals and companies wishing to obtain eventual FDA/CE certification for a device knowing that the raw material itself is listed with the FDA and has already passed specific FDA testing. guidel!ne is sold as a raw material modified in form only into 3d printing line and most important, extruded in a manner that keeps contaminates out of the material during the cooling process, where contaminates and bacteria could be embedded in the soft extrusion. In addition, pH and ORP levels are monitored and adjusted to maintain acceptable levels.

Of course, printing an item with guidel!ne does not mean the item is certified. The certification process for medical/surgical equipment and components is on a part by part/usage certification process with the applicable agency.

Information provided to the user will be in sync with the FDA’s “Technical Considerations for Additive Manufactured Devices Draft Guidance for Industry and Food and Drug Administration Staff”. Section “C” “Material Controls”. While COA’s will be the responsibility of the end user, taulman3D will provide information to support such efforts.

guidel!ne comes on 1 pound spools in either 2.85mm or 1.75mm round. guidel!ne is labeled with a QR code that provides a “traceability and batch key”. Each spool has a Identification number, comes vacuum sealed and ships in its own box. End users will be able to “register” their spool/s with taulman3D. As with other materials from taulman3D, the clarity of guidel!ne allows for visual non- destructive evaluation of the printed part.

3D Printing:

When 3D Printed, guidel!ne has a tensile strength higher than our strongest TECH-G, coming in at 6,850PSI. Elongation is 5.9 and a modulus of 281,469PSI. Heat distortion temp is 70C. Softening temperature is 100C

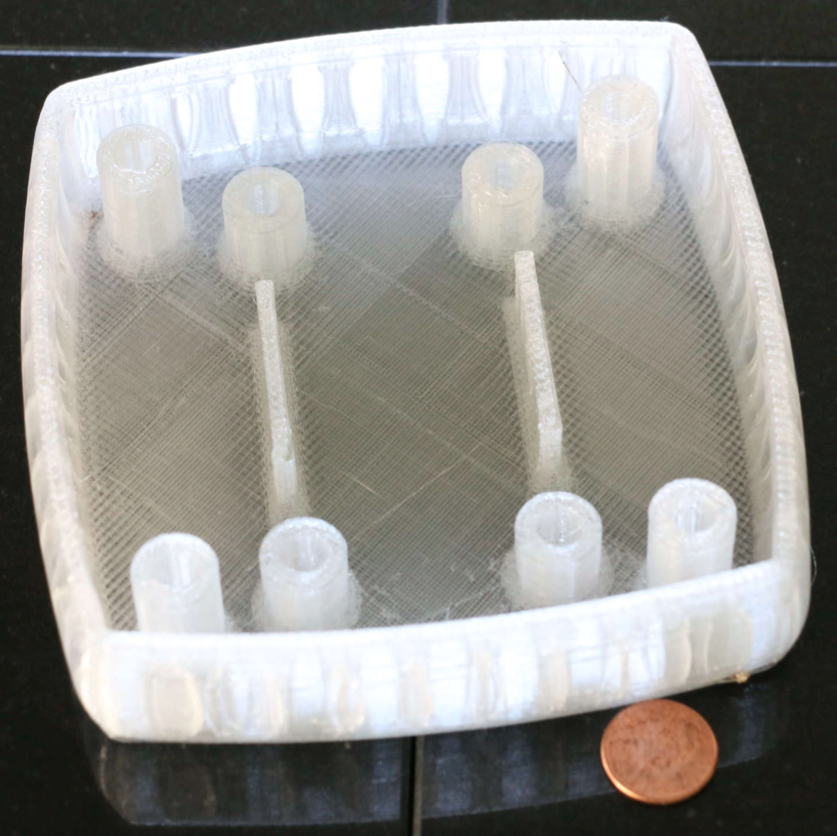

guidel!ne is a clear PETG based polymer that prints at 250C. guidel!ne is very easy to print needing only a small amount of retraction. A key feature of guidel!ne is that one can easily print small hollow tubes without the issue of heat build-up deforming the tube.

guidel!ne’s use as a Support Material:

Another feature of guidel!ne is that it’s higher print temperature allow it to be used as a support material for medical grade Nylon. guidel!ne used as a zero-gap support material works extremely well on Nylon with just enough adhesion to form mechanical support yet easy to remove from parts where mechanical removal is accessible.

guidel!ne is available now at www.taulman3d.com