Brazilian petrochemical firm Braskem has announced the acquisition of 3D printing material developer and distributor taulman3D.

Braskem has gradually broadened its interest in additive manufacturing, first utilizing the technology to produce spares in-house, then launching its own filament range two years ago. Since then, the company has continued expanding its presence in the industry, bringing new eco-friendly materials to market, and it says its taulman3D acquisition could now further “accelerate its growth strategy.”

Braskem’s gradual AM expansion

Headquartered in São Paulo, Braskem is the largest producer of thermoplastic resins in the Americas, and though its activities span multiple industries, it has raised its stake in 3D printing in recent years. Working with the Redwire-owned Made in Space and NASA in 2019, for example, the firm helped develop the Braskem Recycler, a system on the International Space Station that facilitates polymer reuse.

Internally, Braskem opened its Innovation & Technology (I&T) center in Pennsylvania two years ago, complete with a dedicated 2,800 square-meter 3D printing lab, in a move that expanded its R&D capabilities. This was swiftly followed by the launch of Braskem’s first 3D printing materials, a set of polyolefin feedstocks, as well as another polymer developed with EOS subsidiary Advanced Laser Materials.

Working with Titan Robotics, which has since been bought by 3D Systems, Braskem then developed polypropylene pellets for the Atlas 3D printer. Specifically engineered for Titan’s system, the material was said to be optimized for the production of large-format end-use parts, including those with potential automotive, packaging, or live hinge applications.

More recently, the company has sought to expand its eco-friendly offering. At the Rapid+TCT 2022 tradeshow, Braskem’s first sustainable filaments were launched, including a bio-based EVA as well as a recycled PE and PP, all of which were designed to further its circular manufacturing goals.

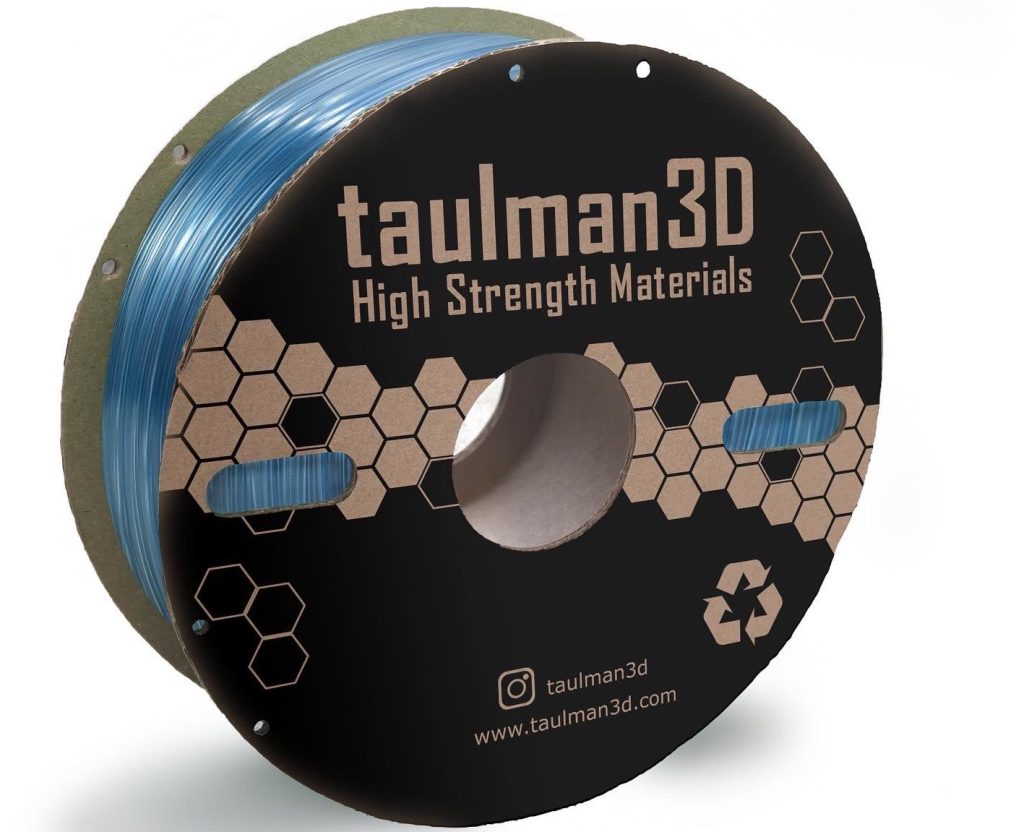

With its acquisition of taulman3D, developer of the 100% recycled Enviro PETG, Braskem now stands to boost its sustainablity credentials even further. For its part, taulman3D President Zach Lichaa says the deal will also provide his company with access to greater R&D resources, enabling it to meet growing demand.

“We’re extremely proud to have built one of the leading 3D printing businesses in the world over the last decade, with private and public sector clients in dozens of countries,” explained Lichaa. “Braskem’s significant research and development resources and their world-class production teams will enable us to serve our clients with even greater focus and product innovation as additive manufacturing becomes increasingly engrained in global supply chains.”

Gaining a greater slice of the 3D printing pie

Though Braskem hasn’t revealed the exact terms behind its taulman3D acquisition, it has provided an idea of the gains it expects to make from the deal. According to the company, taulman3D’s portfolio of nylon, recycled PETG, and PET filaments is “highly complementary” to its own, and is already available via distributors on six continents, broadening its reach.

Additionally, with more than a decade of experience in the industry, Braskem says its acquisition has had time to gain the trust of “thousands of professionals” around the world. These include firms working in aerospace, automotive, healthcare, industrial, and education, lucrative industries that Braskem’s 3D printing offering can now better address.

Perhaps more revealingly, Jason Vagnozzi, Global Commercial Director of Additive Manufacturing at Braskem, has also spoken of the growth opportunities opened up by trading in what he sees as a rapidly-expanding 3D printing space.

“Braskem’s acquisition of taulman3D brings a high-quality 3D filament producer with a globally diversified client list and a highly complementary product portfolio,” explained Vagnozzi. “With projections for the 3D printing industry expected to grow from $15 billion today to $78 billion by 2030 – growing at an estimated 20% CAGR – we see enhanced opportunities to serve this rapidly growing demand.”

“Today’s acquisition doubles Braskem’s market share in the additive manufacturing market and further accelerates our growth strategy.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a spool of taulman3D’s 100% recycled Enviro PETG 3D printing filament. Image via taulman3D.