Brazilian petrochemical company Braskem, will add polyolefin-based filament, powder, and pellets for 3D printing, to its material portfolio.

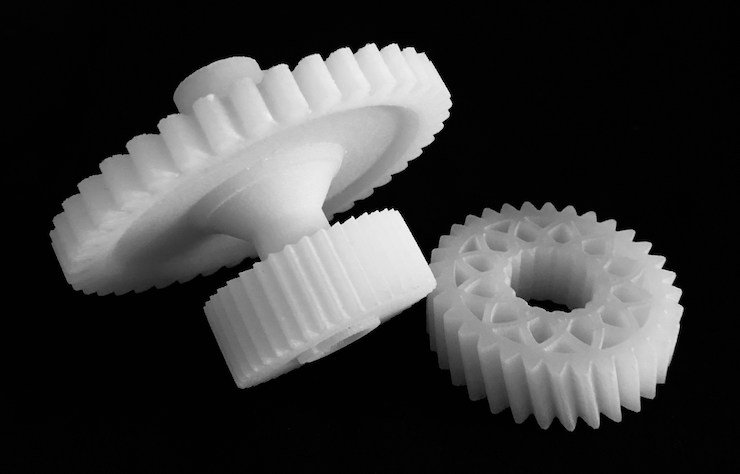

Polypropylene (PP) is a recyclable thermoplastic that displays high impact strength and durability, making it suitable for 3D printing applications such as creating functional prototypes and models.

“We are excited about the capabilities our polypropylene has over other materials, and we believe the variety of formats we have launched today are helping further strengthen the great potential we see for the global additive manufacturing market,” said Jason Vagnozzi, Braskem Commercial’s Director of Additive Manufacturing.

Braskem and sustainability in additive manufacturing

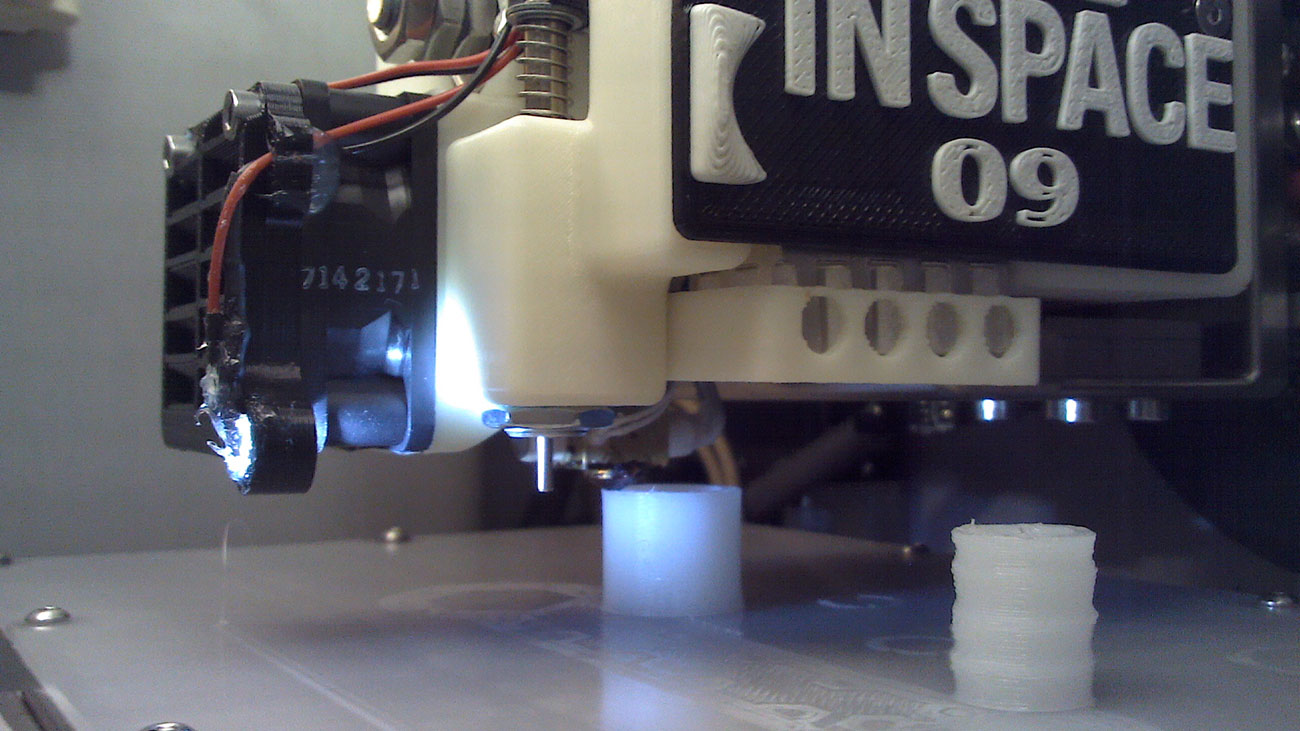

Founded in 2002, and headquartered in Sao Paulo, Braskem utilizes additive manufacturing to reduce the environmental impact of used plastics and chemicals in the aerospace sector. In 2016, the company partnered with US aerospace firm Made in Space (MIS) and NASA, to enable astronauts to 3D print in space using polymers made from sugarcane.

Working with MIS again in October 2019, Braskem developed a plastic recycling facility for 3D printed parts, which will be sent to the International Space Station (ISS) in an upcoming resupply mission. The ‘Braskem Recycler’ project aims to establish a closed-loop manufacturing system, reducing the station’s reliance on resupply missions from Earth.

In December 2018, the petrochemical company expanded its Innovation & Technology (I&T) Center in Pittsburgh, Pennsylvania, and built a dedicated lab for additive manufacturing. The new 2,800-square-meter building houses polymer characterization laboratories for chromatography and microscopy analyses, as well as quality control.

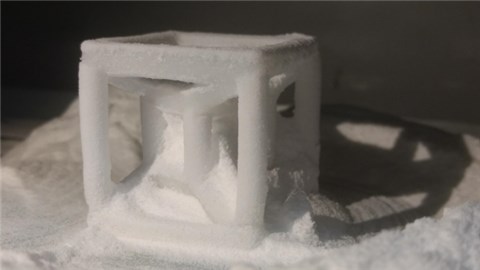

Braskem announced a collaboration with Advanced Laser Materials (ALM), a subsidiary of the EOS company, in 2018. The partnership has focused on developing polyolefin-based powders for Selective Laser Sintering (SLS), and culminated in the launch of their first PP materials.

The new Polypropylene 3D printing materials

The filament format of the polymer is designed for Fused Filament Fabrication (FFF) 3D printers and is available in two grades.

According to Braskem, 3D printed components produced using the filament display similar qualities to those manufactured using Polylactic Acid (PLA), but with improved dimensional stability, chemical resistance and impact strength.

The SLS powders will be co-marketed and sold as part of the ALM product portfolio. Having announced that the thermoplastics were the first to be compatible with its ATLAS pellet extrusion system, Titan Robotics will also act as a redistributor going forward.

Polypropylene in additive manufacturing

PP is the second most widely produced commodity plastic in the world, and a number 3D printing material companies have developed their own versions.

In April 2020, Spanish feedstock manufacturer Recreus launched its PP3D thermoplastic filament. The company released its polymer with a primer, claiming that it allows the material to be printed with ease, delivering “maximum adhesion to the bed”.

German 3D printer manufacturer Apium Additive Technologies, released its low temperature, high resistance PP materials in October 2018. The thermoplastic was designed for use in Apium’s P Series printers, alongside other compatible materials including PEEK, carbon fiber, POM-C, PVDF, and PEI 9085.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the production process used by Braskem and Made in Space to 3D print plastic components in Space in 2016. Photo via Braskem.