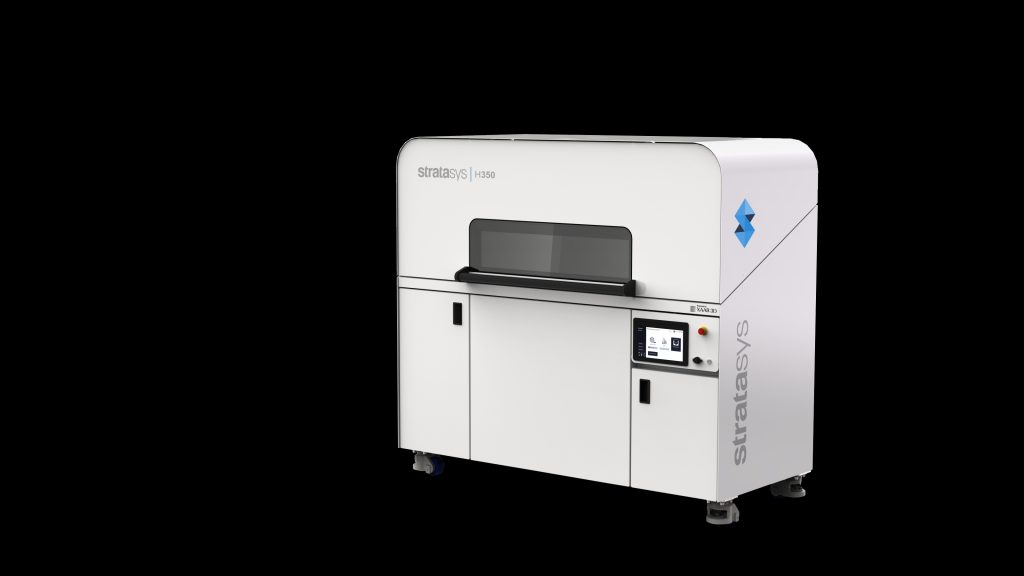

Industrial 3D printer manufacturer Stratasys has made a whole slew of announcements at the RAPID + TCT show, signifying an accelerated shift towards ‘additive manufacturing at scale’.

The announcements include new 3D printing materials for the Stratasys H350 and Stratasys Origin One systems, and a new addition to the GrabCAD Software Partner Program: additive manufacturing software developer AMFG.

Rich Garrity, President of Stratasys Americas, said, “We are at the forefront of the shift to full-scale additive manufacturing, powered by 3D printing, with our best-in-class solutions for the entire product value chain.”

High-Yield PA11 and PA12 for the H350

The H350 operates on Stratasys’ recently launched selective absorption fusion (SAF) 3D printing technology. Designed for production-level throughput and end-use polymer parts, the system will now be able to utilize High-Yield PA11, a sustainable nylon material made of 100% bio-based castor beans.

Additionally, 2022 will see the launch of PA12, a nylon 12 powder characterized by its dimensional stability, chemical resistance, and impact strength. The offering is expected to be used across various industries for jigs and fixtures, tooling, and functional end-use components.

Dura56 and 3D IND405 Clear for the Origin One

Following the acquisition of DLP machine manufacturer Origin at the end of last year, Stratasys launched its own Stratasys Origin One 3D printer. The high-speed programmable photopolymerization (P3) technology ecosystem has now been expanded with two new resins developed in collaboration with chemicals company Henkel.

Stratasys Dura56 is defined by its excellent durability and impact resistance, offering high-quality surface finishes and a low cost per part. Designed for high material use applications and parts where aesthetics and robustness are paramount, Dura56 has use cases in class A surfaces, housings, and parts with mating features.

On the other hand, 3D IND405 Clear is a semi-rigid 3D printing resin that ensures smooth part surfaces, high impact resistance, and excellent elongation. The material is clear in nature but can be machined, tapped, and polished further for applications such as microfluidic devices and guide overlays.

Cindy Deekitwong, Global Head of Marketing at Henkel’s Loctite, adds, “Together we will continue to drive innovation and deliver high-performance photopolymers that will allow engineers to realize the full potential of using additive manufacturing for end-use parts across a wide range of industries.”

Furthermore, Stratasys has also introduced the Origin Open Material License (OML), a software toolkit set to ship this year. With Origin OML, users will be able to experiment with custom workflows on the Origin One, modifying parameters such as light, temperatures, force, velocity, and pressure for full control of the build process.

Expanding the GrabCAD Software Partner Program

The year 2021 has already seen eight software partners added to the GrabCAD Software Partner Program, the latest being AMFG.

The firm is a specialist in Manufacturing Execution System (MES) and workflow automation software for the 3D printing sector, enabling organizations to centralize their operations and streamline processes across departments. Partnering with Stratasys, AMFG’s workflow optimization expertise will now be combined with the GrabCAD software and Stratasys’ systems. As such, the companies’ customers will be able to leverage fully automated order management, routing, and production scheduling.

“The combination of Stratasys hardware, GrabCAD software, and AMFG’s market-leading additive MES platform is a game-changer for AM operations looking to scale through automation, while increasing overall traceability, utilization, and quality,” said Danny Winn, Vice President of Growth and Innovation at AMFG. “The ability to pull data from AM systems into a centralized software solution is not just a nice to have – it’s critical for the future of scalable end-part manufacturing.”

Earlier this month, Stratasys was awarded a $20 million U.S. Navy contract, the largest of its kind that the company has ever received. Set to be fulfilled over the next five years, the deal will see Stratasys supply up to 25 F900 3D printers to the U.S. Navy, in addition to the materials, support, and training needed to run them.

Elsewhere, Stratasys recently became the first Founding Partner of Germany-based venture builder nFrontier’s new Emerging Technologies Center (EmTeCe) in Berlin. The EmTeCe aims to become one of Europe’s leading emerging technology innovation facilities, an R&D center of sorts where creative hardware and software applications will be developed for clients.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Stratasys Origin One 3D printer. Photo via Stratasys.