Argentinian biotechnology firm Stämm Biotech has reportedly closed a $17 million Series A funding round which will help the company accelerate the development of its next-generation 3D printed bioreactor.

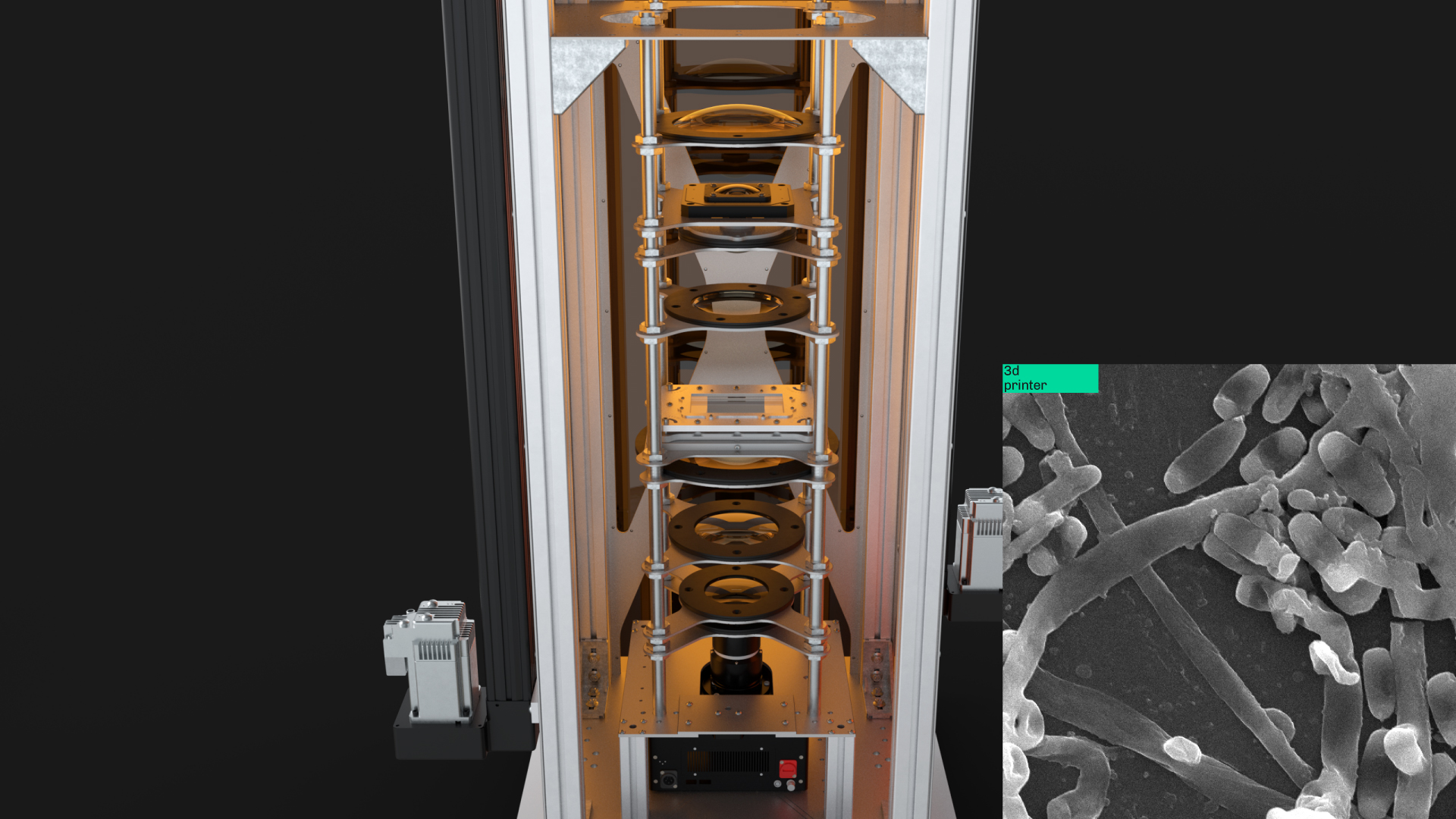

The firm is developing its microfluidics-based bioreactor using its proprietary self-developed Brick Printing Technology which powers its Sclereid 3D printer. According to Stämm, the 3D printer’s capabilities could extend to building the installed capacity of bioreactors worldwide for biopharma in just one year.

Alongside refining its microfluidic bioreactors and associated tools, the company also plans to use the new funds to double its headcount to around 200, and expand its international presence.

Stämm’s novel bioreactor

Industrial-scale bioreactors are large, sterilized tanks filled with a medium within which a specific type of cell or organism can grow. Within most bioreactors, the cell cultures are stirred using a motorized instrument, kept at the desired temperature using coolants, and are supplied with the right amount of oxygen to support their growth.

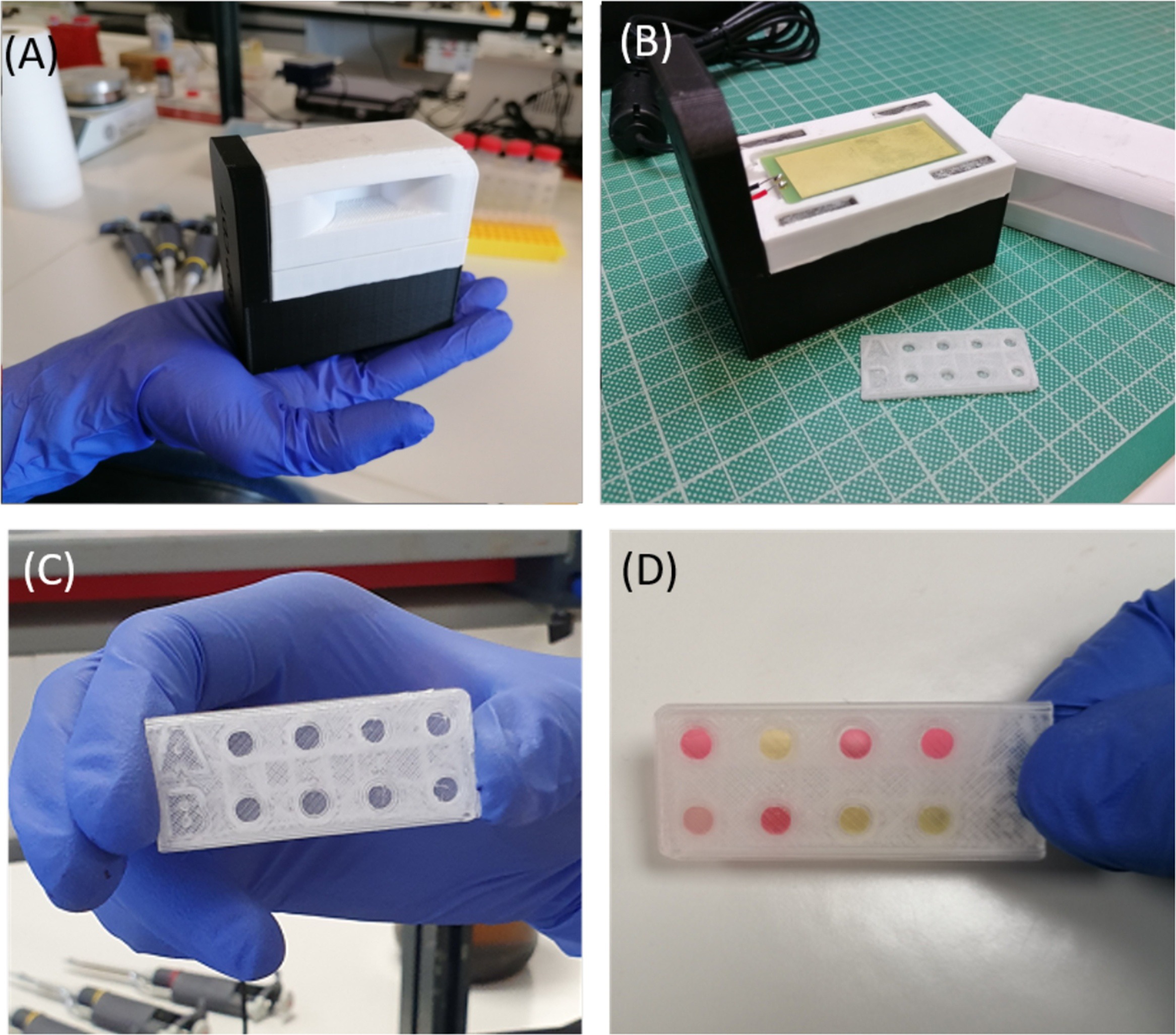

Stämm is seeking to downsize such biomanufacturing facilities into a desktop-sized all-in-one plug-and-play unit, composed of three microfluidic devices. The firm’s bioreactor contains Cell line-on-a-chip to provide a constant flow of available cells to initiate the reaction process, a Bioreactor-on-a-chip function to calibrate parameters like culture medium, PH, dissolved oxygen and cell density, and a bubble-free microbioreactor printed with porous materials.

For the microbioreactor, the firm is deploying 3D printing to fabricate a complex network of microchannels that pass cells through the nutrients and oxygen they need, therefore eliminating the need for tanks, stirring, and tubes. The microchannels keep cells in a continuous, unidirectional, laminar flow and enable the desired mixing of cells, media, and gases to ensure optimal conditions at all times.

The complex nature of the microfluidic channels meant 3D printing was the only technology identified by the firm as being suitable for the task. However, available additive manufacturing processes on the market could not deliver the large surface areas without compromising the size of the pixels. To overcome this, the company decided to build its own machine that could.

Stämm’s Sclereid 3D printer is powered by the firm’s proprietary Brick Printing Technology, which leverages the benefits of printing millions of dots simultaneously with the precision and versatility of laser-based printers. Equipped with a 29-liter printing volume, the Scleroid is capable of printing 590 million pixels per second of six microns in size and up to 983 million pixels per layer.

Having developed the Sclereid, Stämm then used the machine to 3D print the microbioreactor for its desktop biomanufacturing facility. Not only is the bioreactor up to 200 times smaller than many of its traditional industrial counterparts, but it also claims to increase productivity by an estimated 70 times.

The $17 million Series A funding round

The $17 million raised through Stämm’s Series A funding round brings the company’s total funding to date to $20 million. The firm will use the funds to continue the development of its 3D printed bioreactor and enter the early stages of commercializing the technology.

Stämm will allocate a portion of the funds to doubling its headcount to around 200 employees and to expanding its international presence. The capital injection will also help the firm to further refine and develop the tools required to control its biomanufacturing facility.

The latest funding round was led by asset management firm Varana, and saw participation from new investors Vista, New Abundance, Trillian, Serenity Traders, Teramips, and Decarbonization Consortium. Stämm’s existing investors Draper Associates, SOSV, Grid Exponential, VistaEnergy, Cygnus Draper, and Dragones VC also supported the round.

Stämm told TechCrunch it has five potential new partners in pipeline, and plans to enter “pilot scale” for its bioreactor later this year.

Advances in 3D printing bioreactors

Additive manufacturing has been leveraged for various bioreactor designs in the past, for instance by scientists from the Massachussetts Institute of Technology (MIT) and the Indian Institute of Technology Madras. The team developed a novel 3D printed microfluidic bioreactor capable of growing self-organizing human brain tissue for a cost of just $5, which could provide a low-cost alternative for drug testing and developing treatments for illnesses like dementia.

Elsewhere, researchers from the University of Crete have previously 3D printed bioreactors for DNA amplification purposes, while Cornell University scientists have 3D printed a microscopic bioreactor capable of fabricating synthetic intestines.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Stämm Biotech’s Bioprocessor, containing the firm’s 3D printed microbioreactor. Image via Stämm Biotech.