The DIY 3D printing community is a vital source for improvements and breakthroughs in the industry, and these heroes often share their innovations without a face or a name. One of these unsung Makers who frequents the hobbyist forum and idea-sharing RC Groups website, who goes by the alias Harcoreta on the forum, has developed an incredible 3D printed jet engine out of their home base in Madrid, Spain.

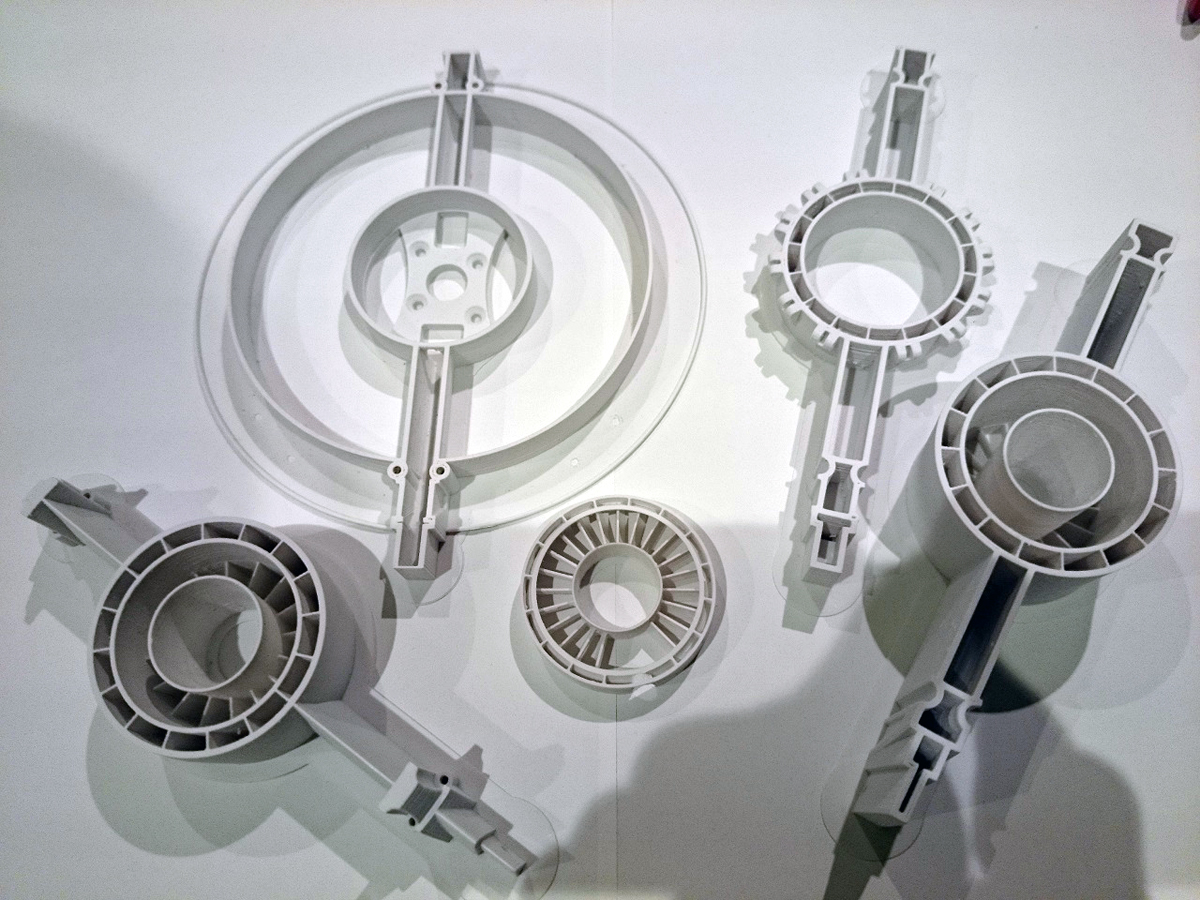

The 3D printed Boeing 787 jet engine doesn’t just look like an exact replica of its predecessor, it also functions similarly to the original model. Not to mention that the entire project was printed out of ABS plastic on a Prusa i3 3D desktop printer, proving that aerospace ingenuity can come from within our very own homes. Equipped with a working thrust reverser, the forum user Harcoreta went through the process of trial and error in order to bring the engine replica to life.

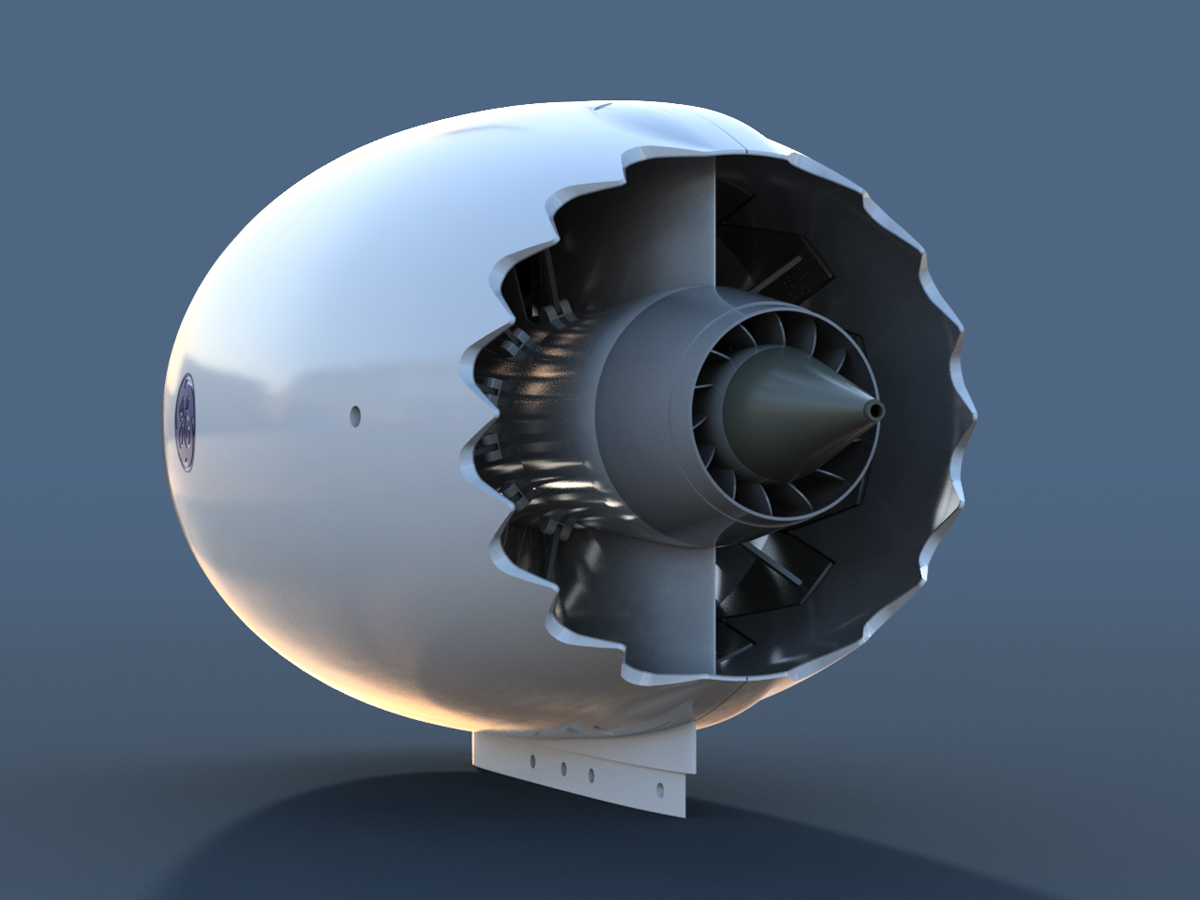

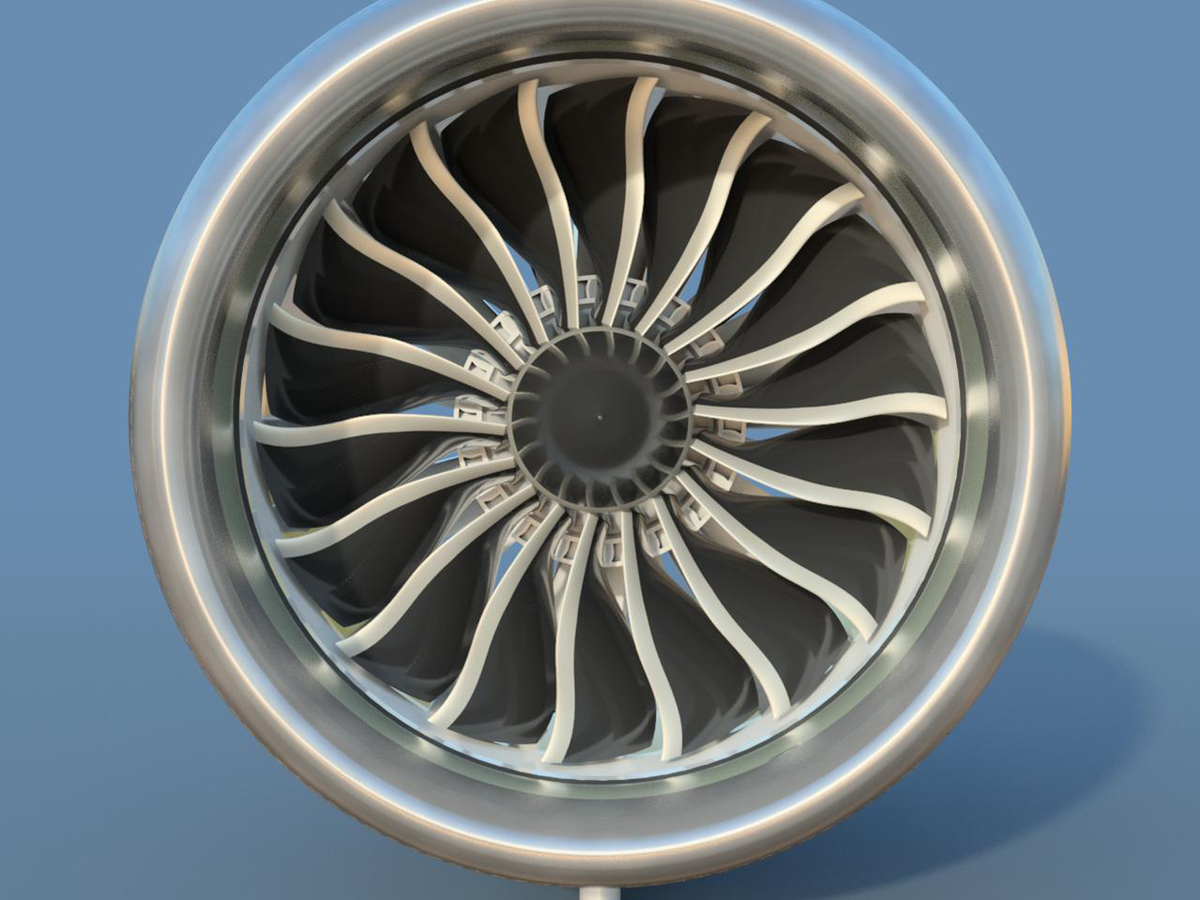

Harcoreta built the first prototype last year, an 18-blade electric ducted fan (EDF), which initially functioned well, but the overwhelmed stock motor attached to the EDF eventually overheated, causing Harcoreta to remodel with the help of his RC Group forum peers. The outcome was indeed a success! Deciding to replicate the General Electric GEnx turbofan design, scaled for the Boeing 787 jet plane, this Maker was certainly aiming to keep the high quality of the design at a fraction of the cost.

The newly designed 3D printed replica of a Boeing 787 turbofan is still equipped with the 18 blade set up, but now includes an internal turbine to cool the engine, a thrust reverser, and a more simplified engine pylon too. The numerous parts to this turbofan are beautifully rendered, and it seems as though only the motor was not created through the 3D printing process. Once the design is completed and fully printed, Harcoreta will proceed to test the turbofan by mounting it on the topside of a Bixler RC plane and giving it a test flight.

What this innovation proves is that anyone with access to a 3D printer has the opportunity to replicate and build upon our industrial production from days of the past. The most important factor, aside from self-motivation, is having a strong community like RC Groups to bounce ideas around with. After taking advice from forum members to make the first prototype even better, Harcoreta is still seeking feedback for the next go around. Projects like this remind us of why 3D printing is such a unique and accessible method to create almost anything, and thanks to one RC Group user from Spain, we will hopefully be able to watch the additive manufacturing industry soar higher and higher up into the sky of 3D innovation.