Researchers from the Pohang University of Science and Technology (POSTECH), and Kyungpook National University School of Medicine, South Korea, have 3D bioprinted an artificial cornea.

According to the research published on Biofabrication, there are approximately 2,000 patients waiting over six years for cornea donations in South Korea as of 2018. In an effort to find a faster treatment, the scientists integrated corneal tissue-derived ink (stroma) to emulate the transparency of a human cornea for possible implantation.

Professor Jinah Jang, Creative IT Convergence Engineering, POSTECH, said, “The suggested strategy can achieve the criteria for both transparency and safety of engineered cornea stroma. We believe it will give hope to many patients suffered from cornea related diseases.”

Replicating the human eye

The cornea is the thin outermost layer that covers the pupil which protects the human eye from the external environment. This layer is the first that admits light, thus it needs to be transparent and flexible. As stated by the study, because of its various functions, it is difficult to develop an artificial cornea using biocompatible materials such as synthetic polymers as it lacks transparency.

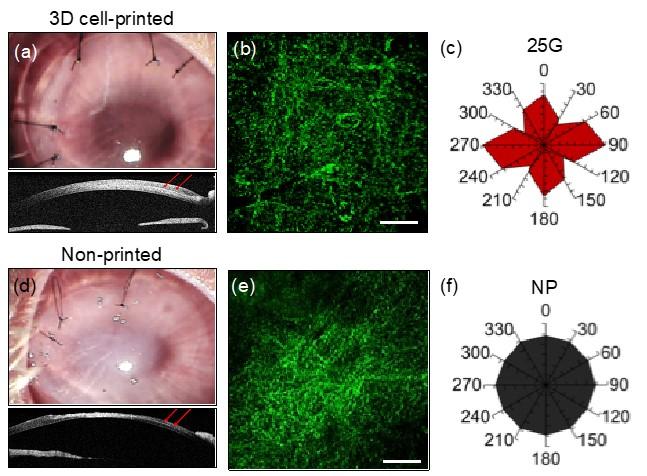

According to the researchers, “The human cornea is organized in a lattice pattern of collagen fibrils. The lattice pattern in the cornea is directly associated with the transparency of the cornea.” To recapitulate such a structure, a 3D bioprinting method using shear stress was generated.

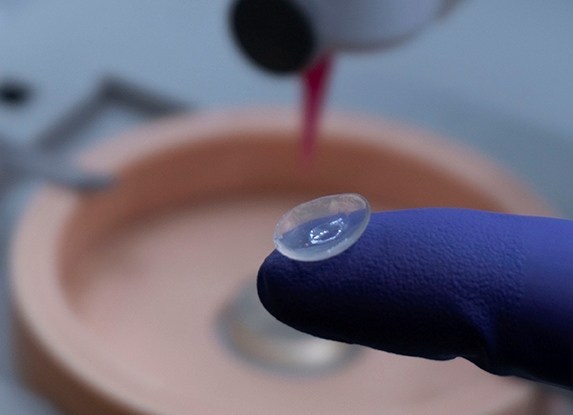

This meant that the diameter of the printing nozzles was adjusted on the scientist’s custom 3D bioprinter to obtain a flow that would best produce the desired lattice structure.

A 3D bioprinted cornea

Shear stress in 3D bioprinting takes into consideration the viscosity of the bioink, the flow rate, and the inner diameter of the nozzles. The bioink used in this experiment, corneal decellularized extracellular matrix bioink, has shear-thinning properties.

By regulating the shear stress to control the pattern of collagen fibrils, the researchers were successful in creating a 3D bioprinted cornea. The study concludes, “Because the alignment of collagen fibrils occurs along the shear force direction during extrusion, shear-related 3D printing parameters can be used to spatially control the orientation of collagen fibrils within the constructs.”

“Interestingly, the collagen fibrils remodeled along the printing path created a lattice pattern similar to the structure of native human cornea after 4 weeks in vivo.”

“Taken together, the capability of controlling collagen orientation opens a new avenue of engineered tissue design and optimization, in which composition and biomimicry within a 3D object can be integrated with component design to achieve a highly

optimized structure.”

Combatting blindness with 3D printing

Tackling blindness through 3D bioprinting-based corneal treatment has been a common interest from scientists worldwide. Since 2017, researchers from the University of Sydney’s Save Sight Institute and University of Wollongong have been developing the iFix Pen, a hand-held co-axial 3D printer, extruding bioink directly onto an eye to aid in the regeneration of cells on corneal ulcers.

In 2018, a team at Newcastle University (NCL) saw a breakthrough for eye treatments by successfully 3D printing a human cornea. Another NCL team then came up with the foundations for the next stage of 3D bioprinted corneas with the potential of self-curving, “4D” corneas.

Elsewhere, Dr. Song Hongxin, an ophthalmologist and researcher at the Beijing Tongren Hospital, China, 3D printed spectacles to help patients with deformed corneas. Most recently, Pandorum Technologies Pvt., a Bangalore-based biotechnology company, used 3D bioprinted cornea tissue to promote scarless healing of wounds in the eye.

“Shear-induced alignment of collagen fibrils using 3D cell printing for corneal stroma tissue engineering” is co-authored by Hyeonji Kim, Jinah Jang, Junshin Park, Kyoung-Pil Lee, Seunghun Lee, Dong-Mok Lee, Ki Hean Kim, Hong Kyun Kim, and Dong-Woo Cho.

It’s your last chance to tell us who you think are the leaders of additive manufacturing. Vote in the 2019 3D Printing Industry Awards.

Also for latest additive manufacturing news, subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a close-up of the human cornea. Photo via iStock.