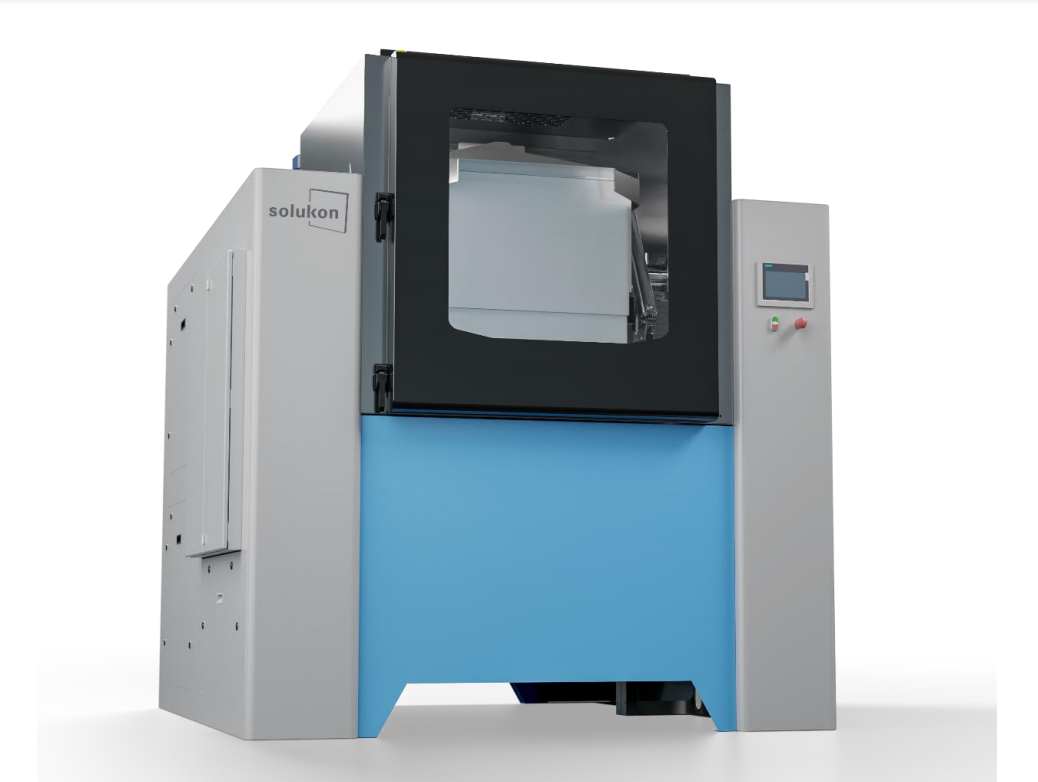

Post-processing system manufacturer Solukon Maschinenbau has announced the launch of its latest automated de-powdering machine for polymer parts fabricated on SLS systems. The new Solukon SFP770 will be demonstrated at the Formnext Connect online event, which is currently taking place. The Solukon team will also be live streaming virtual visits to their facilities, where the rest of the machines in the company’s portfolio will be on display.

Andreas Hartmann, Technical Director and Co-Founder of Solukon, explains: “Our latest system is an automated solution for industrial processing of powder-based AM parts. With the launch of the SFP770, we bring the benefit of years of experience in the depowdering and unpacking of metal AM parts to polymer AM applications. We look forward to presenting to the AM community our latest innovation in AM powder removal technology, this time for the removal of polymer powders.”

Powder removal with the SFP770

The SFP770 has two key functions – the first is to remove excess powder from a full build box (unpacking), and the second is to clean the remaining powder off individual printed parts (cleaning). Unpacking can be done with or without cleaning, and a fully loaded build box (up to 150 liters) can be post-processed in 30 minutes. The machine also features its own powder recycling system, enabling users to reuse any unfused powder that is reclaimed.

The system has the capability to do all of this in a hand-free manner, without exposing the user to any loose powder. Additionally, the two functions of the machine are completely programmable, whereby the time, drum revolution speed, tumbler angle, and air jet velocity are all closely controllable.

The benefits of automation

The manual depowdering process is undoubtedly a major bottleneck in the industrial 3D printing workflow. It is not only time-consuming, but labor-intensive as well, as it requires experienced technicians to painstakingly clean parts of any fine residue. Even then, there is the issue of human error, as it is very likely that over a large number of parts, there will be inconsistencies in the cleaning results.

The SFP770 claims to remedy these issues, all while doing so in a safe manner. A high level of digitization also means the machine is able to interface easily with other robots and guided vehicles on the shop floor, improving workflow efficiency.

Michael Sattler, Global Sales Director at Solukon, adds: “The SFP770 offers significant benefits for customers looking to industrialize their AM operations, such as labor cost savings and health and safety concerns. We are confident that our solution is an important milestone that will meet the needs of customers seeking to take their AM manufacturing operations to the next level.”

Automated post-printing system manufacturer PostProcess Technologies also recently announced the launch of a new technology family. Dubbed Variable Acoustic Displacement (VAD), the patent-pending polymer powder removal technology is specially designed for use with SLS and MJF 3D printed parts.

Similarly, post-processing system manufacturer Additive Manufacturing Technologies (AMT), together with blasting equipment manufacturer Leering Hengelo, also launched two new de-powdering systems specifically for 3D printed parts. The PostProDP and the larger-capacity PostProDP Pro operate with a range of abrasive blast media, including corundum, glass beads, ceramics, nut shells, plastic, and steel grains.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Solukon SFP770. Image via Solukon.