Post-processing system manufacturer, Additive Manufacturing Technologies (AMT), has partnered up with blasting equipment manufacturer, Leering Hengelo, to launch two new de-powdering systems for 3D printed parts. The PostProDP and the larger-capacity PostProDP Pro are designed to automatically clean excess powder off laser powder bed fused parts.

Automated post-processing

According to UK-headquartered AMT, around 60% of the manufacturing costs of laser powder bed fused parts go toward the post-processing stage, which is currently highly manual. More often than not, a human is required to adequately de-powder a part before it can be used for its application, which can be costly and slow.

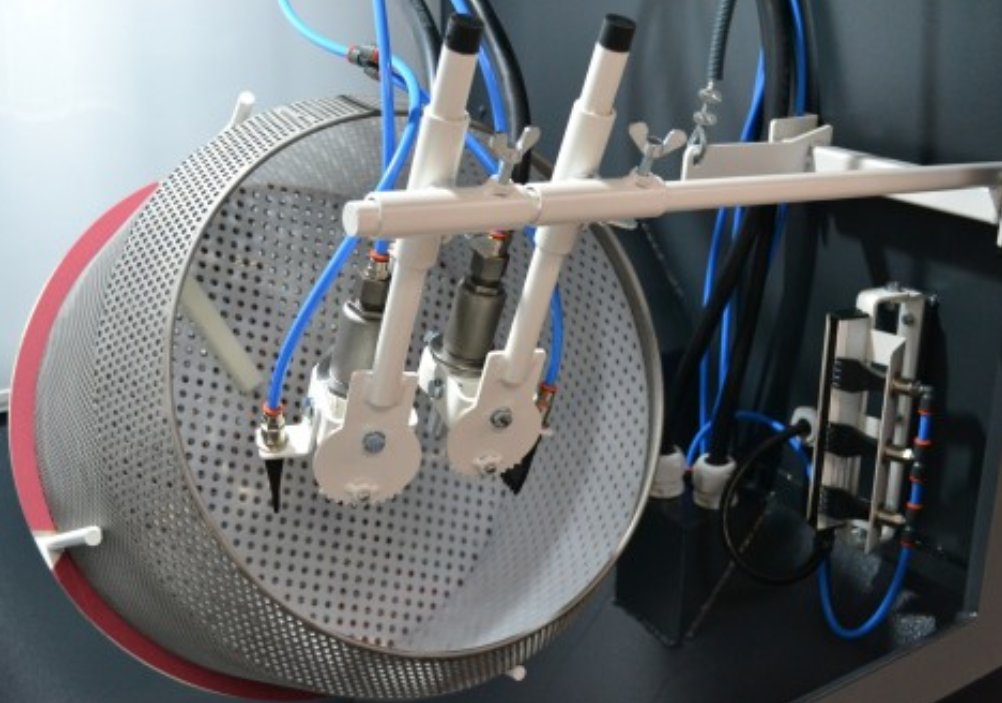

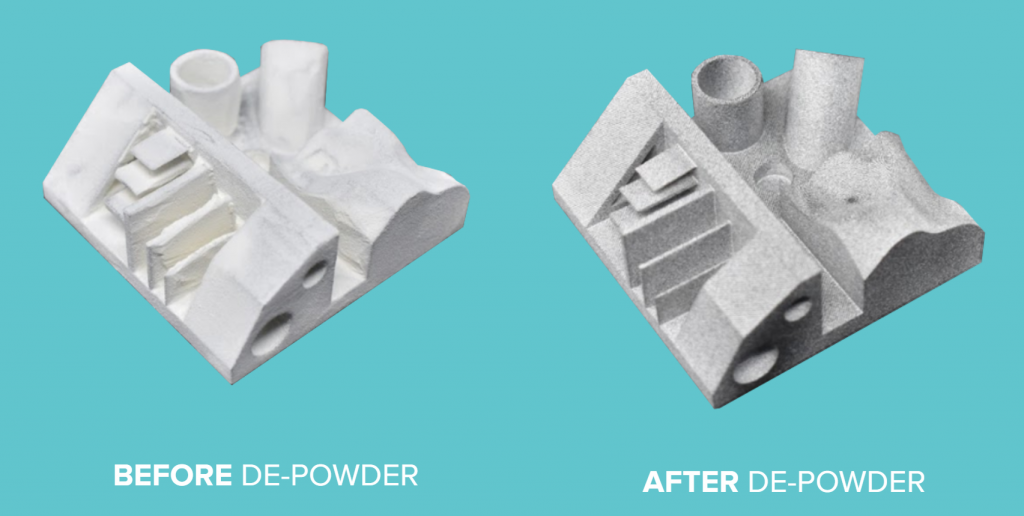

The PostProDP range aims to remedy the painstakingly inefficient process, providing a method of depowdering industrial parts with high throughput. The CE and ATEX certified systems are focused on user safety and an efficient user experience. An adjustable and removable internal tumble basket aims to minimize fine powder leakage while completely cleaning parts of excess powder. It is aided by a set of ionizing nozzles that blast parts in the chamber, ensuring every crevice is cleared out. Both systems also feature a “recipe-controlled” PLC controller which is preloaded with default parameters for a number of common materials, giving users the ‘plug and play’ option.

Joseph Crabtree, CEO of AMT, stated: “AMT’s vision is to develop fully automated safe and sustainable post-processing solutions to enable the industrial production of additively manufactured parts at scale. We first achieved this with the successful commercialization of the PostPro3D vapor smoothing system. De-powdering is the next key bottleneck in the post processing chain, and PostProDP goes a long way to mitigate many of the current issues with cleaning AM parts. We are delighted to be partnering with industry experts Leering on this industry critical mission.”

Adaptable and compatible

The PostProDP systems are feedstock adaptable, and work with all powder-based 3D printers including HP MJF systems, EOS systems, and 3D Systems machines. Additional material profiles also cover polyamides and elastomers. Both systems can operate with a range of abrasive blast media, including corundum, glass beads, ceramics, nut shells, plastic, and steel grains. The machines are able to completely clean excess powder off parts in ten minutes with no damage whatsoever. The PostProDP and the PostProDP Pro are available to order now from AMT.

André Gaalman, CEO of Leering, concluded: “Leering are experts in surface finishing with 80 years of experience in machine design and production for surface treatment. We export our machines, branded Normfinish, worldwide. The partnership with AMT will allow us to strengthen each other’s positions in additive manufacturing and offer our joint customers globally the best solution for their post-processing needs. We’re excited to offer our customers each other’s solutions and bring a next generation of postprocessing solutions to the market.”

The PostProDP is just the latest addition to AMT’s extensive portfolio of AM post-processing systems. Almost two years ago, the company launched its proprietary PostPro3D platform which sports an internal volume of 600 x 400 x 400mm. It is capable of processing 3D printed parts created using MJF, Laser Sintering, High Speed Sintering, and FDM technology. More recently, at Formnext 2019, AMT unveiled its large-scale comprehensive post-processing system, the Digital Manufacturing System (DMS).

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows AMT PostProDP systems. Image via AMT.