Sigma Labs, the computer-aided inspection (CAI) software company behind the PrintRite3D software has announced that it has released Version 3.0.2 of its PrintRite3D INSPECT In-Process Quality Assurance (IPQA) software, which will now be available independently or as an upgrade to existing Sigma Labs customers.

“We are thrilled to achieve this milestone in our development lifecycle as we believe it is a real game-changer for the industry. This release represents a significant step forward towards “closing the loop” in process quality monitoring and control”, said John Rice, Sigma Labs’ CEO.

PrintRite3D and its role in part quality assurance

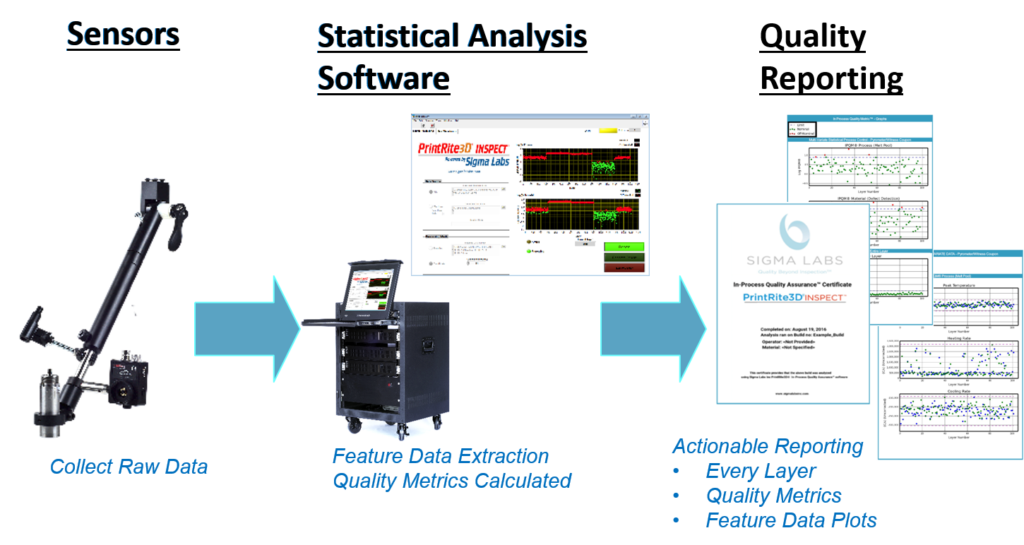

PrintRite3D INSPECT 3.0.2 follows version 3.0 of the software, which was launched at Formnext 2017. INSPECT analyzes the raw data from the PrintRite3D SENSORPAK multi-sensors and hardware installed inside a 3D printer.

Using an In-Process Quality Metric (IPQM) called Thermal Energy Density (TED) to monitor the 3D printing process, INSPECT quantitatively measures the melt pool (he pool of molten metal liquid produced while the laser is heating up the powder) and part quality of the metal additive manufacturing run.

INSPECT then feeds this data into further PrintRite3D CONTOUR and ANALYTICS software modules to produce quality reporting.

Sigma Labs has used PrintRite3D software package to certify aerospace components manufactured by Honeywell, and solar turbines from Caterpillar Inc.

A cost-saving software upgrade to Inspect 3.0

INSPECT 3.0.2 takes this further, by enabling process engineers to produce an alloy-specific process map using the TED data. This process map data can then be combined with customer-specific post-process quality to cost and establish operating processes for parts.

Also included in the INSPECT 3.0.2 software is a production-level package of statistical process control (SPC) software apps, which monitors the serial production quality at a build, part, layer or scan level to ensure continuous operation.

Finally, INSPECT 3.0.2 features enhanced TED technology, making it easier to correlate quantitative melt pool data with quantitative post-process quality metric data that can be measured during non-destructive tests (such as finite element method), metallography, or destructive tests.

Altogether, the upgrades to the INSPECT software enable rapid process qualification, which could result in increased production leads, and faster product to market times.

Want to design the trophy for year’s awards? Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design now to win a 3D printer.”

For more stories on 3D software, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

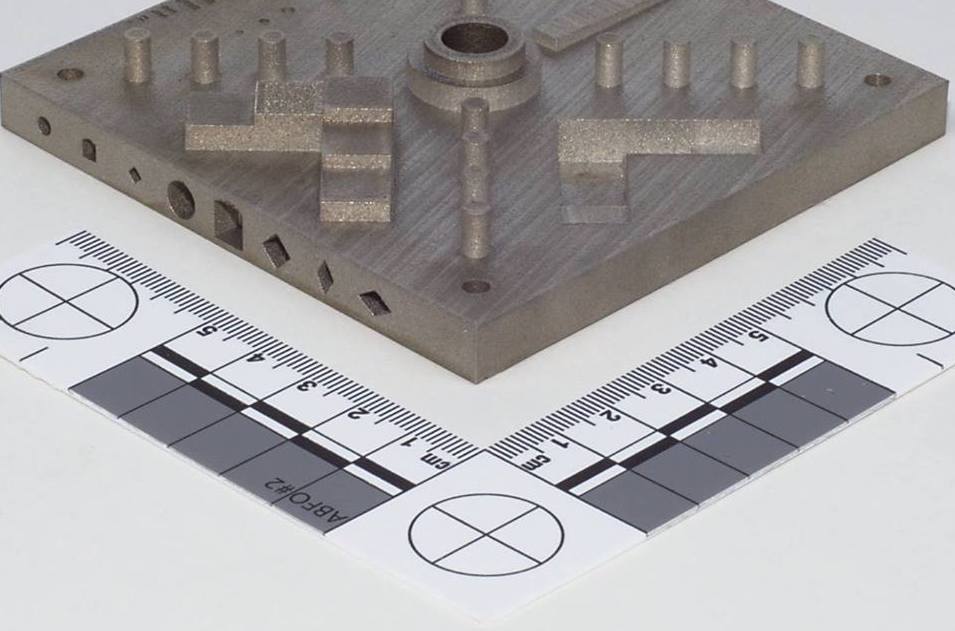

Featured image shows Planetary Gears 3D printed using PrintRite3D inspection software. Features the motto “Quality Beyond Inspection” Photo via @Sigmalabsinc on Twitter.