Sigma Labs, the computer-aided inspection (CAI) software company behind PrintRite3D software, has received a Test and Evaluation Program contract from an undisclosed global materials and service provider in additive manufacturing.

Under this contract, Sigma Labs is installing its PrintRite3D INSPECT 4.0 in-process quality assurance software into several additive manufacturing systems in the customer’s German and U.S. facilities.

“Sigma Labs is deeply committed to our In-Process Quality Assurance tools, supporting and moving forward with them,” said John Rice, CEO of Sigma Labs.

“I am confident that this initiative, which marks our fifth customer signed from diverse industries in the past four months, will validate our PrintRite3D technology in commercial-industrial serial manufacturing settings.”

PrintRite3D INSPECT 4.0

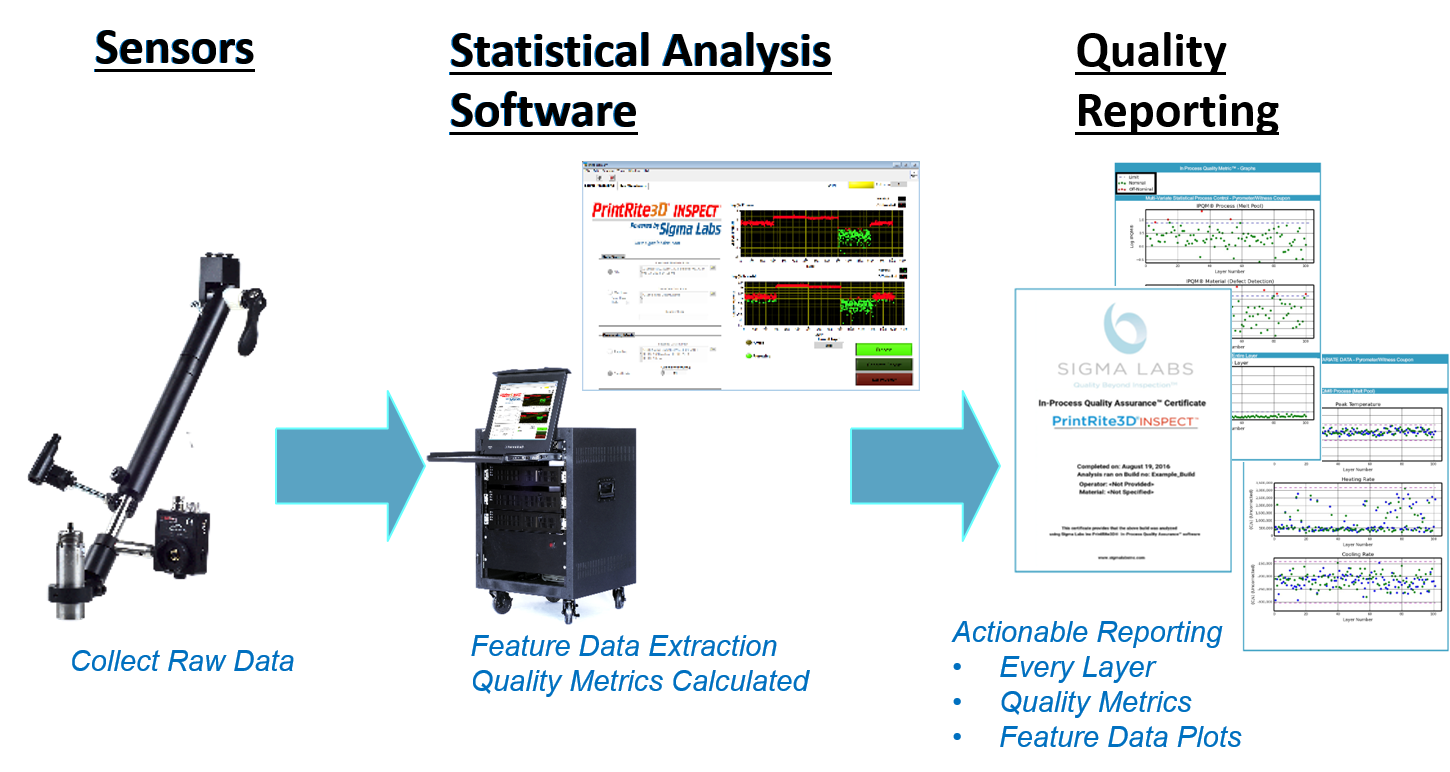

Launched last year at Formnext, PrintRite3D INSPECT 4.0 is the latest version of Sigma Labs’ In-Process Quality Assurance (IPQA) software. This technology works in tandem with the company’s SENSORPAK hardware, which features off-axis and on-axis in-process sensors to, collect real-time data on additive manufacturing processes.

Furthermore, some of PrintRite3D INSPECT 4.0 features include objective evidence of compliance to design intent; Early defect detection; Scrap reduction and increased yield; Melt pool spectral data evaluation; And tools for reporting melt pool relative temperature.

Rice adds, “We believe that going forward, AM technology will play an increasingly prominent role in the aerospace, medical, power generation/energy, automotive and tooling/general industries, all areas which are served by this customer.”

The Sigma Rapid Test and Evaluation Program

The Sigma Rapid Test and Evaluation Program aims to demonstrate the value of PrintRite3D. As such, the technology is assessed on its product capabilities and performance as well as its ability to validate and quantify the repeatability of industrial 3D printing processes.

As the fifth customer of the program, the undisclosed company will receive hardware, software, training, engineering and metallurgical consulting, and support services from Sigma Labs.

Prior to this, Sigma Labs has won contracts from Solar Turbines Incorporated, a subsidiary of Caterpillar Inc, and DARPA and Honeywell Aerospace to advance metal additive manufacturing. Furthermore, a strategic alliance with metal additive manufacturers Morf3D based in El Segundo, California was announced in February 2017.

Nominate for the upcoming 3D Printing Industry Awards 2019.

For more 3D printing software updates, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows planetary gears 3D printed using PrintRite3D inspection software. Photo via @Sigmalabsinc on Twitter.