The 3D printing industry observes further maturation of metal additive manufacturing in Sigma Labs and Morf3D’s quality control alliance.

Headquartered in Santa Fe, New Mexico, 3D software developers Sigma Labs Inc. (NASDAQ:SGLB) has formed a strategic alliance with metal additive manufacturers Morf3D based in El Segundo, California. By joining forces, the two companies are strengthening the quality of services offered to their clients.

Mark Cola, President and CEO of Sigma Labs explains,

Due to the growth in demand for 3D printed metal components within the A&D [Aeropace & Defense] industry, we’ve decided to join forces to better serve a number of OEMs with their next-generation applications. Working together, we can design, engineer, manufacture, and assure the quality of AM components across a number of exciting A&D opportunities, and existing contracts are anticipated to dramatically impact Sigma Labs’ growth trajectory beginning this year.

Quality control of metal additive manufacturing for aerospace

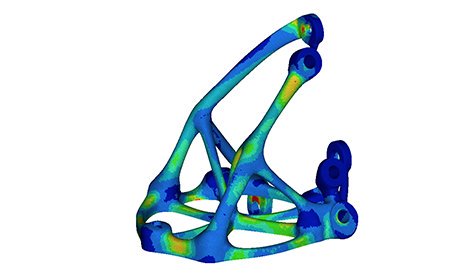

Sigma Labs will be adding their proprietary PrintRite3D software system to Morf3D’s expertise to enhance the process of quality control for 3D printed metal components.

PrintRite3D is a platform for analysing and inspecting all aspects of metal components from the design through to real-time 3D printing. It measures geometry of parts layer by layer, and collects information from machines to identify trends in manufacturing that may be causing a particular defect or finish.

Morf3D is an industrial 3D printing bureau that offers Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM, as provided by Swedish company ARCAM AB) services, alongside post-processing and subtractive manufacturing.

Morf3D is also backed by an Additive Manufacturing Innovation Center in El Segundo. First opened in 2015, the Innovation Center specialises in the research and development of materials, 3D design and training.

The collaboration advances a current trend in the 3D printing industry for consolidation of services. Earlier in February 2017, CNC milling and hybrid machining specialist DMG MORI became the majority shareholder of selective laser melting (SLM) 3D printing company REALIZER. The deal also adds to Morf3D existing non-exclusive aerospace partnership with Altair product designers, and Swiss technology company RUAG.

Featured image shows moveable Planetary Gears 3D printed using PrintRite3D inspection software. Features the motto “Quality Beyond Inspection” Photo via @Sigmalabsinc on Twitter