A 3D printed burner inside a Siemens SGT-700 gas turbine has reported one full year of operation. Installed at an E.ON combined cycle power plant in Hesse, Germany, the burner inside the turbine has been running for over 8,000 hours and shows no signs of slowing down.

3D printing for gas turbines

Siemens started investing in 3D printing as early as 2008, and has been implementing the technology specifically for power generation.

Its award winning 3D printed turbine blades for the SGT-400 gas turbine, a world-first validation, made their debut in 2017. As of this year, the SGT-A05 aerospace engine now features a metal 3D printed combustion component, and oil sealing rings recently became the first additively manufactured parts for Siemens industrial steam turbines.

The 3D printed burner now installed in the SGT-700, is the product of several years of investigation at the company, starting with an adapted EOS M280 SLM 3D printer for burner repairs. It has been produced as part of the Siemens intelligent burner manufacturing (IBUMA) in Finspång, Sweden, with the collaboration of E.ON Energy Projects.

Additive manufacturing proves to be “a game-changer”

Typically, a burner inside a turbine engine would be composed of 13 individual parts, welded together at 18 points. With 3D printing, the burner is now made in a single piece, reducing the risk of weaknesses that can occur in its joins.

According to the company’s fact sheet eighty SGT-700s, containing the 3D printed burners, have been sold worldwide, generating a total of more than 1.7 million equivalent operating hours.

Speaking of its 8,000 hour run at E.ON in Germany Vladimir Navrotsky, Chief Technology Officer for Siemens Power Generation Services, says:

“These early results from the IBUMA burner with E.ON validate our belief that this technology is a game-changer.”

Niklas Lange, project manager at E.ON Energy Projects, adds, “As an energy service provider, precision and consistency are an absolute requirement for us. Additive manufacturing not only delivers this, but in our experience it can even improve performance compared with older models.”

For all of the latest additive manufacturing news subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter. Looking for jobs in engineering? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

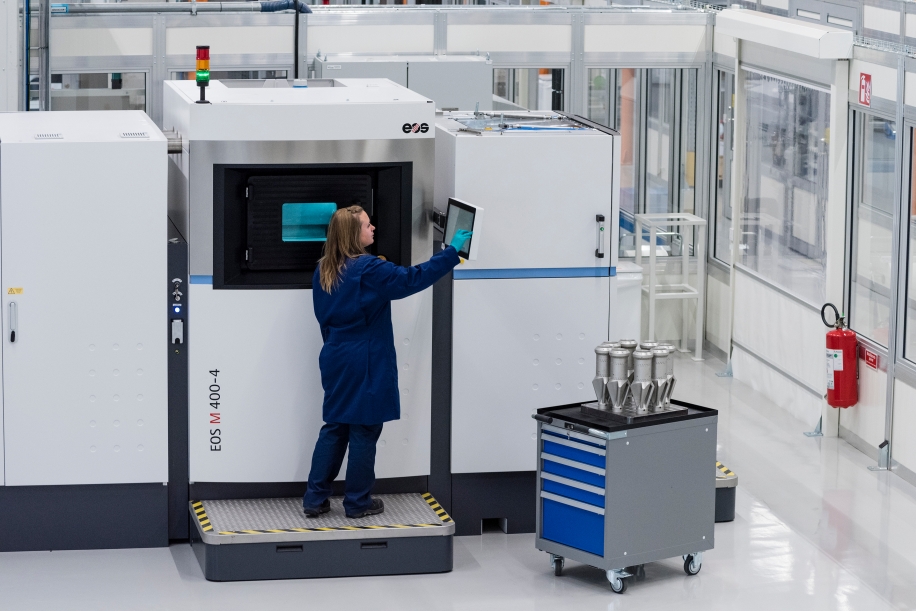

Featured image shows a Siemens SGT-700 industrial gas turbine. Image via Siemens