3D printing marketplace and service bureau Shapeways has added new SLA materials to its portfolio. Customers will now be able to produce parts such prototypes and short-run production components, in three acrylate-based materials.

“At Shapeways, we want to ensure our customers are empowered with the tools to take their innovations and creativity to the next level, and with that comes the ability to scale,” said Greg Kress, CEO of Shapeways. “We’re excited to introduce SLA to further diversify our range of materials, so as to meet each product’s specific need.”

An expanding Shapeways portfolio

With an ethos to “redefine product creation”, Shapeways’ platform offers a wide range of on-demand 3D printing manufacturing services to its creators – which amount to over one million. Currently, such customers span across 140 countries.

Its services include EOS’ Selective Laser Sintering (SLS), Stratasys’ full-color, multi-material 3D printing, Carbon’s Digital Light Synthesis (DLS), and Multi-jet fusion technology from HP. Combined, these services offer more than 60 materials, enabling a variety of products from consumer to medical to be produced.

With new SLA capabilities the company adds to its vat polymerization portfolio. Specifically, the company has adopted the Accura range of resins made by 3D Systems.

Acrylate-based materials for 3D printing

The three new SLA materials selected by Shapeways are Accura 60, Xtreme and Xtreme 200.

Accura 60 is a clear, durable plastic for quickly producing rigid and strong parts with the aesthetics of molded polycarbonate (PC). It is suitable for general-use applications including tough prototypes, display models, lighting components and fluid flow visualization models. Compatible with the ProX 950 and ProX 800 3D systems machines.

Accura Xtreme is a tough grey plastic that resists breakage and handles challenging functional assemblies. Similar to polypropylene and ABS, it is impact resistant, durable and has good dimensional accuracy. Ideal applications include: snap-fit assemblies, enclosures for consumer and electronic products, master patterns for vacuum casting and general purpose prototyping. Compatible with the ProX 950, ProX 800, ProJet 7000 HD and ProJet 6000 HD 3D systems machines.

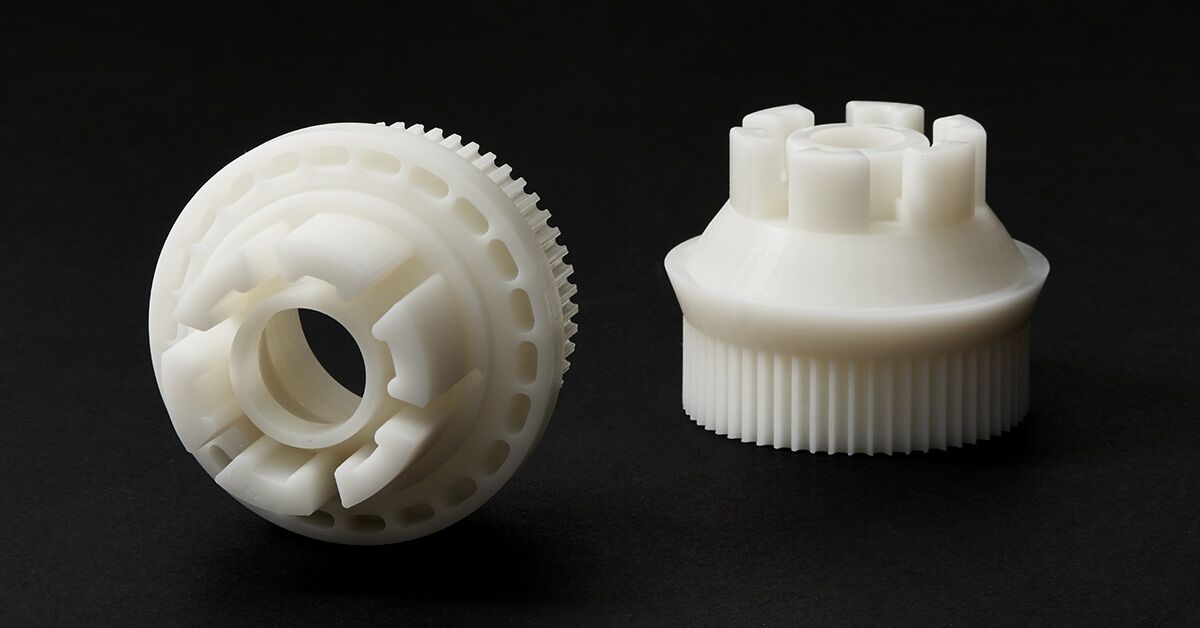

Lastly, Accura Xtreme 200 is a durable white plastic also with excellent dimensional accuracy and aesthetics to replace CNC-machined polypropylene and ABS. It offers high elongation at break, high impact strength and quality stiffness and durability. Similarly to Accura Xtreme it’s ideal for form, fit and function prototypes, enclosures for consumer electronic components, general purpose prototyping, master patterns for silicone molding. Compatible with the ProX 950, ProX 800, ProJet 7000 HD and ProJet 6000 HD 3D systems machines.

Subscribe to the 3D Printing Industry newsletter and follow us on Facebook and Twitter for the latest news in additive manufacturing.

Visit our 3D Printing Jobs board to find new opportunities in the 3D printing industry.

Featured image shows parts printed out of Accura Xtreme 200. Photo via Shapeways.